Food: meeting standards and preventing foreign contamination

Checkweighers, metal detectors, weighing platforms, X-ray inspection systems, and recipe management tools for all formulation processes: Minebea Intec provides advanced technologies designed to ensure quality and increase productivity.

Strict international regulations such as HACCP, ISO 22000, and NSF set high standards for hygiene and quality in food production. To meet these standards, while also coping with rising costs of raw materials, energy and labour, manufacturers must depend on technologies that combine reliability and precision. Minebea Intec provides customised technological solutions designed to meet these needs, as summarised below.

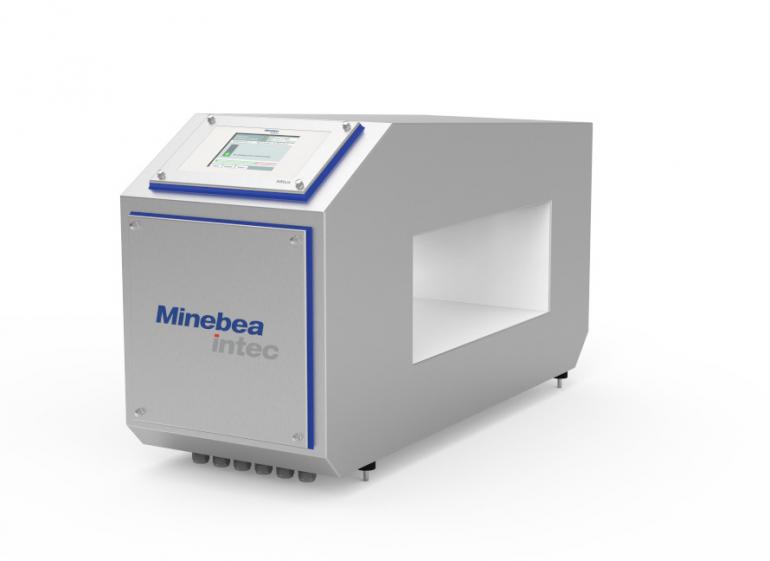

Technologies for HACCP. The HACCP preventive food safety system requires manufacturers to identify potential hazards (biological, chemical, physical) and define critical control points (CCPs) to eliminate them. Minebea Intec's Mitus® metal detector, featuring MiWave technology, is ideal for monitoring these critical points. Its high sensitivity allows it to detect even the smallest metal particles, contributing to product safety.

In addition, X-ray inspection systems, such as those in the Dymond series, not only detect metal contaminants but also other foreign bodies, including glass, stones, plastics, and bones. These systems also check packaging completeness and product quality, enabling manufacturers to meet international hygiene standards.

ISO 22000 standards and traceability. ISO 22000 outlines the requirements for food safety management and works in conjunction with HACCP to ensure safe and traceable production of food. Minebea Intec's dynamic checkweighers support compliance with these standards by monitoring product weight in real time. In addition, the new Blue HMI simplifies the interface of the scales, enhancing efficiency and optimising traceability and production.

Software for traceability and recipe management. Minebea Intec also provides software solutions, such as SPC@Enterprise and ProRecipe XT®. SPC@Enterprise collects and stores quality and production data, enabling rapid identification of products in the event of an issue. ProRecipe XT® supports formulation processes by ensuring accurate dosing of ingredients, which is particularly useful in highly regulated industries such as food production.

NSF certification and the MiNexx 3000. NSF certification ensures that Minebea Intec's weighing and inspection systems meet the highest standards of hygiene. In fact, the NSF-certified MiNexx 3000® weighing platform is specifically designed for the food industry. Its hygienic design reduces the risk of contamination and makes cleaning easier. Its high level of precision ensures that products meet the required fill quantities.