Carton sleeving sector: the evolution

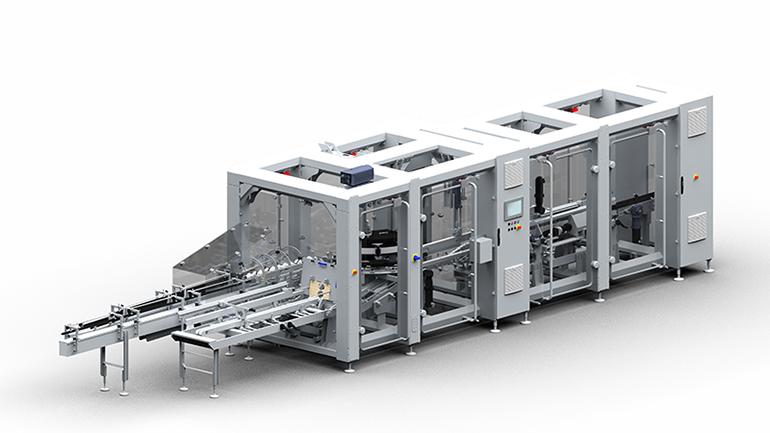

Cama Group proposes the MP series of cardboard sleevers for the packaging in cardboard of multiple products, that stand out for their technological innovation and high added value, including accessibility, ergonomic design, performance and functionality.

Devised for the packaging of bottles, cups, jars, bricks, tins/cans and thermoformed containers from single and/or double lane in up to three product layers in cardboard sleeves, the various electronic models of the series guarantee a high workability without encumbering hindrances.

- Sleeving machines for complete folding sleeve bottom closing MP 91-136. Electronic cardboard sleeving machines for packing bottles, cups, jars, bricks, tins/cans and thermoformed containers from single and/or double lane in up to three product layers. These machines are suitable for complete carton folding sleeves with product neck in and/or neck out. Cardboard sleeve closing is accomplished by means of hot-melt gluing on the bottom of the packs.

- Sleeving machines for pass through and wrap-around sleeve top closing MP 106. Electronic cardboard sleeving machines for packing bottles, cups, jars, bricks, tins/cans and thermoformed containers from single and/or double lane in up to three product layers. These machines are suitable for pass through carton sleeves as well as for complete folding sleeves with upper pack closing by means of hot-melt gluing.

- Sleeving machines for bridge or clip type sleeves MP 103-104. Electronic cardboard sleeving machines for packing bottles, cups, jars, bricks, tins/cans and thermoformed containers from single and/or double lane in one layer. These machines are suitable for clip type carton sleeves as well as for bridge sleeves with upper pack closing by means of hot-melt gluing.

Cama’s patented cardboard sleeve design is available.

Find out more information about the companies mentioned in this article and published in the Buyers' Guide - PackBook by ItaliaImballaggio

Cama Group