CEFLEX recommends use of recyclable mono-materials for flexible packaging

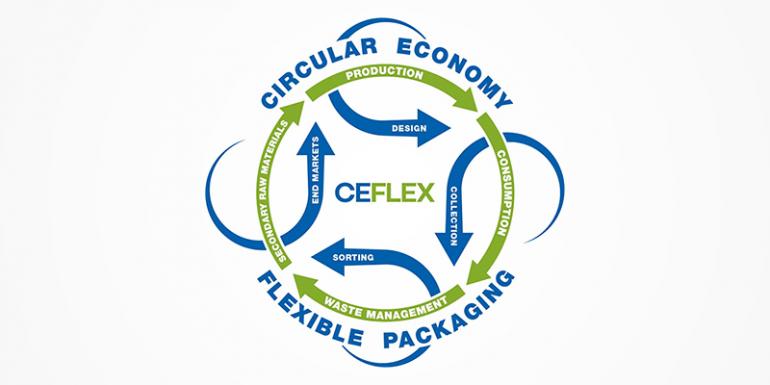

As part of its ‘Issue Alignment’ process CEFLEX stakeholders are working with Swiss University ETH to collect and assess topics which are essential to realising a circular economy for flexible packaging. The result has been its first Position Paper on ways to achieve this goal entitled ‘Accelerating the circular economy for flexible packaging – a recommendation for recyclable mono-materials’ is now being made available.

Taking into account the current best-practice technologies established in Europe, CEFLEX strongly recommends the use of flexible packaging made from recyclable mono-materials.

The paper clearly states the need to evaluate functional requirements of packaging and, when possible, to redesign existing flexible packaging to a recyclable mono-material. This recommendation chimes with the recently released CEFLEX ‘Designing for a Circular Economy’ guidelines, which gives practical advice and clarity on how to deliver significant environmental improvements without compromising functionality.

“Ensuring packaging is designed to be recycled into new, valuable materials, or flows back into the economy, is a cornerstone condition for creating a circular economy,” explained CEFLEX project coordinator Graham Houlder. “More than 80% of flexible packaging is mono-material Polyethylene (PE) or Polypropylene (PP) and we can grow this further; which will improve conditions for investment in infrastructure and help create sustainable end markets for the recycled materials.”

The next priority for CEFLEX stakeholders is to examine collection models for flexible packaging in a circular economy and produce another position paper, after analysis of separate collection and post sorting of residual waste.