Ecodesign: key to the circular economy

Insights from the Spring Circular Economy Summit. Trends, policies and benchmarks in environmental sustainability. The role of education and legislation.

Maurizio Cacciamani

The “Circular Economy Summit - Artificial Intelligence and Circular Economy Models: towards a regenerative industrial ecosystem” was organized by Business International, a division of Fiera Milano, last March.

From the various speeches, the role of planning, training (to spread more culture and awareness) and that of national and European legislation (to establish common rules) clearly emerges, so as to transform the criticality of waste and production waste into an economic opportunity.

International testimonies

More circularity = less risk. New industrial models arising from regenerative industrial ecosystems were discussed by Alice Bodreau, Strategic Partners Manager at Ellen MacArthur Foundation. According to Bodreau, the circular economy is key to combating climate change and offers new and improved opportunities for growth and reduced risk profile. An analysis of 222 European companies from 14 different sectors found that the higher a company’s level of circularity, the lower the risk of debt default at 1 year and 5 years.

The rules need to be common

For Rob Dellink, Senior Economist at OECD, circularity must be a common goal globally; therefore, international cooperation is essential, standardizing criteria for resource use, aligning the production framework and legislative framework. It is essential to develop common rules that incentivize recycling. Out of 50 countries analyzed today, unfortunately, only 13 incentivize recycling activity.

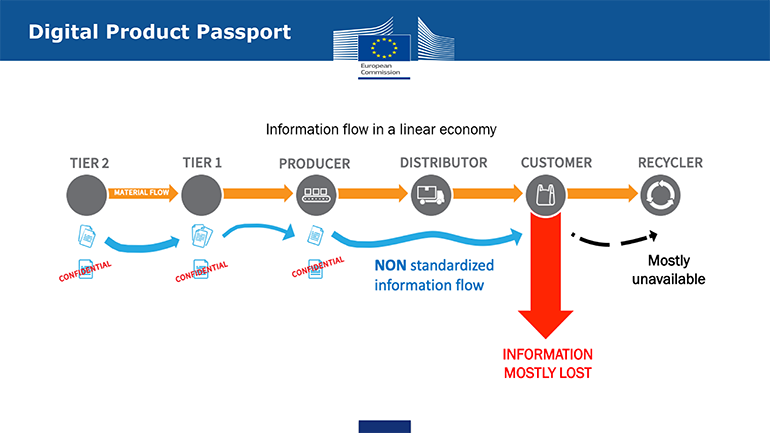

The digital product passport

William Neale, DG Environment’s Directorate B-Circular Economy at the European Commission, spoke about the European action plan, the second edition of which will be available soon, which will focus on the value chain. For Neale, in Europe, sustainable products must become the norm not the exception; therefore, minimum requirements must be established for a product to be placed on EU markets. Hence the design of the digital product passport that can be consulted online, which will allow all product data to be tracked, encouraging its recycling or repair and increasing its average life.

With the NRP 2.5 billion for the circular economy

Of the economic incentives aimed at promoting shared policies, pushing recycling and monitoring waste management told Laura D’Aprile, Head of Department of Ecological Transition and Green Investment at the Ministry of Ecological Transition. Tied to the funds are two structural reforms: the “National Strategy on Circular Economy” and the “National Plan for Waste Management” with the aim of closing the gap between Italian regions. 600 million euros are earmarked to create specific disposal hubs for e-waste, paper and cardboard, plastics, textiles.

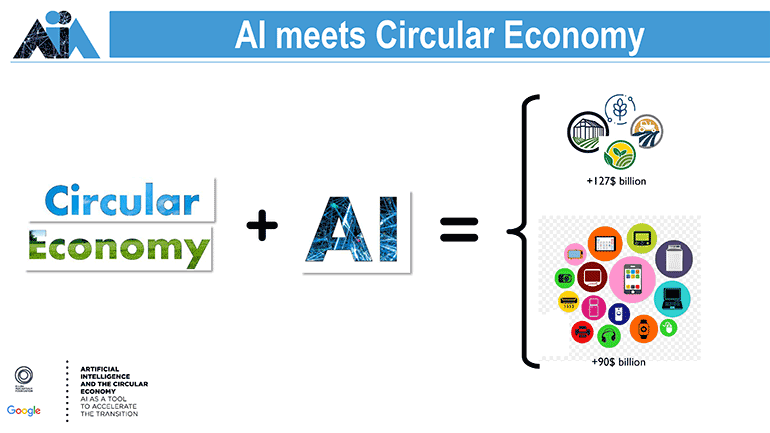

Artificial intelligence to accelerate development

The talk by Gianluigi Greco, Full Professor in Computer Science and Engineering at the University of Calabria, President of AIxIA- Italian Association for Artificial Intelligence and member of EurAI, delved into the interaction between circular economy and artificial intelligence and the role of AI as an accelerator of a new business model. Three areas in which AI can make a concrete contribution are:

- automated design, which makes it possible to design products and materials with specific characteristics, automating extremely complicated work, helping, for example, to produce low-toxicity alloys and materials;

- predictive maintenance, which makes it possible to understand what the residual life of a product is and prospect for a possible second life;

- robotics and vision for automatic detection and separation of materials.

CEO testimonies

The second part of the Summit featured a panel discussion, which was addressed by CEOs of numerous companies, who showed projects and solutions for the circular economy. We will focus on those applications related to the world of packaging.

Sustainability starts with design

For Giulio Bonazzi, CEO of Aquafil, we need to focus on legislation, in terms of waste management and trade also at the international level. Education is very important, because where there is “culture” there will be better recycling management and informed people are more willing to spend for the environment.

Finally, ecodesign: the sustainability of a product starts from the conception, because the design will take into account the life of the products, aiming for longer life, their reusability, reparability and the use of processing waste.

Recovering 25 t of CO2

Christophe Rabatel, CEO of Carrefour, explained the strategy put in place back in 2013 in collaboration with all stakeholders (employees, shareholders, suppliers, institutional partners) to reuse packaging. Carrefour’s Italian subsidiary has done very well, developing projects for packaging savings, food waste reduction, and consumer awareness.

By 2025, 100% of private label products will be either reusable or compostable, thus recovering 25 t of CO2. With local suppliers Carrefour has plans in place for new circularity models in organic waste and packaging. Fundamental then is the fight against food waste, which goes hand in hand with initiatives to raise awareness among users-and producers-to make the right choices in the area of circularity.

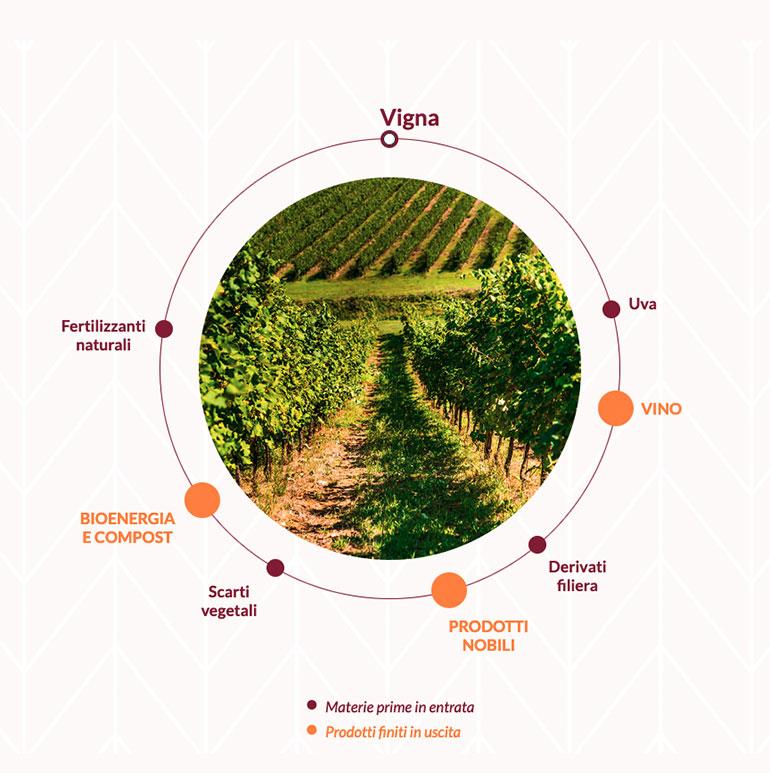

In addition to wine, thermal and electrical energy

Simon Pietro Felice, CEO & General Director of CAVIRO Group (an Italian producer of wines also marketed abroad), told how other products such as alcohol, natural dyes, polyphenols, and bioenergy can be obtained from pomace or pruning waste. The company also produces the thermal and electrical energy it consumes only 50%, and is the first Italian producer of biomethane. Among the newly developed products, Felice mentioned natural fertilizers that are reused in vineyards. Together with the Port of Ravenna, Caviro is developing biohydrogen studies that should be completed in 3-4 years.

Sustainability and social impact

Sara Scrittore, Vice President and General Manager, Southern Europe Hub at Colgate-Palmolive remarked that Colgate has, right now, 11 initiatives to eliminate plastics waste and reduce the consumption of new plastics by 1/3: by 2025, all products will have to use only recyclable plastic.

Each year 22 billion toothpaste tubes are made that are not recyclable therefore destined for landfill. In partnership with recycling companies, Colgate has developed an HDPE plastic tube that can be recycled while retaining all the characteristics that distinguish the tubes now in use.

From plant to mouth

“Control chocolate from plant to mouth!” this is the secret revealed by Lamberto Vallarino Gancia, CEO of Domori - Illy Group. By controlling the entire supply chain, Domori achieves a circular economy as it reuses raw materials discarded in the production of chocolate (Criollo of very high quality) for alcohol production and animal feed, but also for the production of cellulose-free paper by Favini. The project also includes training courses for farmers who, thanks to special economic incentives, are enticed to take part.

A holistic view of packaging

Francesco Pintucci, CEO of Isem Group, pointed out that paper packaging is a major cause of pollution even though it makes extensive use of a natural product such as cellulose, of which Isem Group is a producer. During the pandemic, with the boom in e-commerce, paper packaging experienced a surge.

Isem is working to give packaging a second and even a third life: easy said but not done, as production processes need to be changed. In addition to mentioning the need to develop new materials for packaging, Pintucci pointed out that packaging is a marketing tool for which a contradiction is in place: we talk about sustainable packaging but not sustainable marketing.

The circular economy will only materialize when there is a balance between user needs, sustainable packaging and marketing that is also sustainable.

Gasifying plastics

Pierroberto Folgiero, CEO & Managing Director of Maire Tecnimont, addressed the topic of upcycling: mechanical upcycling has the limitation of decaying the performance of plastics that, after multiple cycles, must be sent to landfill (the absolute evil for the circular economy!). Gasification of plastics that are difficult to recycle makes it possible to obtain other plastics from the source plastics turned into gas. Unfortunately, few technical solutions to the problem are available on an industrial scale.

Has the product been stored well?

The label tells you so. Valentina Pasqui, Owner & Managing Director of Pasqui Coating Converting Printing Company, in recalling that the group’s companies have been ISO 14001 certified since 2008 while since 2011 it has been SFC certified (the main mechanism for guaranteeing the origin of wood and paper), explained the company’s policy of using materials from renewables to the exclusion of fossil fuels, reducing waste and scrap, and increasing energy efficiency. Of note are the patented label that ensures the product has been stored at the right temperature and studies to make it easier to remove the label from bottles for less water consumption.

New packaging materials

For Giuseppe Di Martino, CEO of Pasta Di Martino, anything that is not circular has a higher cost. Hence the choice made 25 years ago to participate in Slow Food, to keep the carbon footprint under control, to eliminate unconsumed food waste (in collaboration with Massimo Bottura), to monitor energy consumption quarterly, the study of new packaging materials (paper or polypropylene), and the establishment of decentralized warehouses to overcome delayed deliveries.

The problem of food monoportions

Massimo Zonca, Board member of Poplast, explained the Competence Center founded by the company specializing in flexible packaging where experts in packaging, materials, and compostability work in a circular perspective. The first results were the development of new materials for compostable food monoportions and new toothpaste tubes. It is complex to recycle food monoportions, as they are soiled with food residues, and that is why Poplast preferred compostability, studies of which were also developed with the help of universities.