Maximum flexibility for facing market demands

Beckhoff and Syntegon together with a new range of modular packaging solutions.

Syntegon’s British subsidiary, global supplier of process and packaging technologies for the food and pharmaceutical industry, has teamed up with the automations specialist, Beckhoff, to extend its portfolio of modular packaging solutions. The partnership aims at the development of a cartoning machine for the food industry that integrates flexibly and anywhere in a production line, without occupying space with bulky control cabinets.

BEC cartoning machine with AMP8000 servo drive

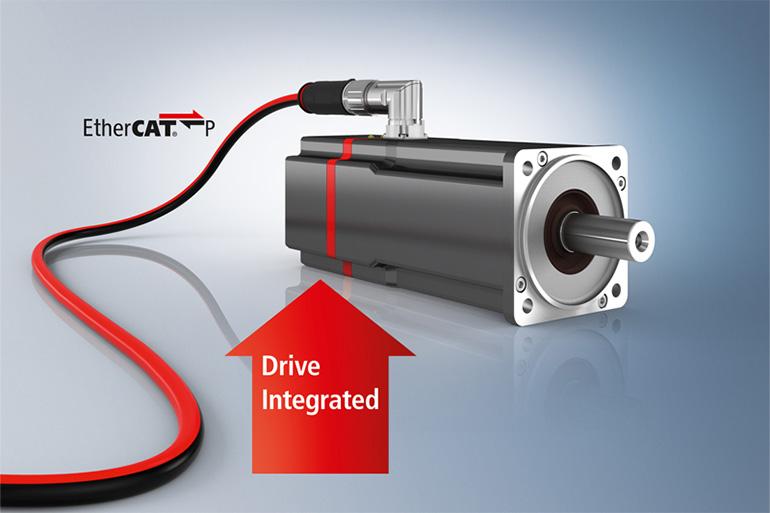

The BEC cartoning machine uses the AMP8000 system, which makes it possible to shift the servo drive from the traditional electrical panel to the machine. The AMP8000 distributed servo drive system consists of a combination of tried-and-tested AM8000 servomotors with a highly efficient servo drive and power electronics with cold switch technology which limits loss of power to levels never seen before.

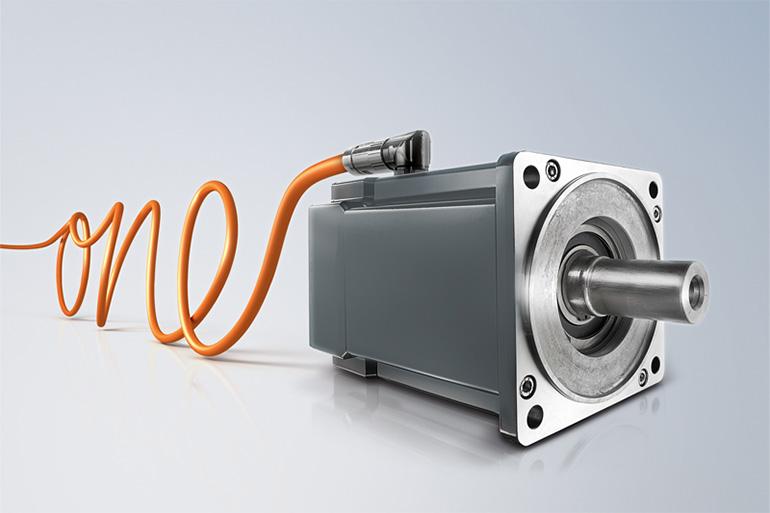

In addition, it reduces the space necessary for electronics assembly to a minimum. At the same time, the motor maintains almost all its original dimensions, avoiding the need for a bigger transmission and obtaining almost the same performance levels as a comparable motor/servo drive combination without connected power electronics.

The integrated single-turn or multi-turn encoders make it possible to use the AMP8000 in applications in which functional safety is required. In most cases, moreover, it’s possible to do without a mechanical limit switch. The AMP8000 is connected with a EtherCAT P cable; other connections are not necessary for operation.

Efficiency and flexibility with systems integration

With the support of the AMP8000 system, designers can fully integrate the drive technology into the machine design. Various servo systems can therefore be connected together to allow for a significant energy exchange. The shift to servo technology has also made it possible to ideally synchronize the different drive components, ensuring a repeatable positioning of the products and obtaining a high level of flexibility and reliability of the equipment produced.