Smart solutions at the service of the digital transition

Specialist in motion plastics, Igus offers innovative technology and solutions for automation, summed up in the “Enjoyneering” concept.

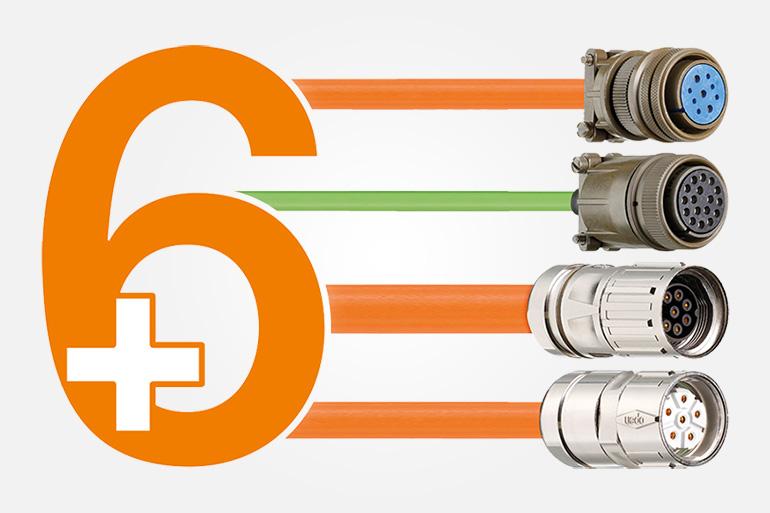

At the SPS in Parma, Igus is presenting new sample programmes provided free of charge to accelerate the setting up of drylin motor control systems and connection to higher-level PLCs. There is also a wide range of online instruments developed to simplify design and engineering works. A new release of Sistema Esperto, which makes it possible to configure and order a system for cable chains ready for connection in only three passages, which integrates, directly online, the exclusive i.Sense EC.W sensor for monitoring conditions and wear, is also being previewed at SPS. Igus’s offer of pre-cabled chains has also been extended, in particular with the readycable range, adding to the 24 already in the catalogue, products compatible with 6 drive system manufacturers. In this way, Igus guarantees an offer incorporating 6,000 pre-assembled cable solutions available throughout the world.

Engineering of the future

From a production point of view, this is the application in the field of the corporate claim to "become the easiest company to deal with": Enjoyneering. The Next Level Engineering according to Igus has, in fact, guided its presence at Hannover Messe, where it previewed 190 new developments. The rhythm of digitalization aims, in fact, to allow the user to find the right motion plastics solution in an easy and enjoyable way, without producing CO2 emissions and plastic waste, thanks to evolved solutions such as the industrial metaverse and new industry 4.0 services.

Iguverse: the industrial metaverse

It’s a parallel virtual world in which, thanks to a VR visor, it’s possible to use a robotic arm in virtual reality. Here, the movements of the visitor are replicated in real time, creating a bridge between the real and virtual world. In Iguverse, engineers and designers join forces to create 3D models of new machinery, systems and vehicles in 1:1 scale; this all occurs in the absence of costly and polluting transfers while developing products in a more rapid, sustainable, affordable and cost-effective way.

Industry 4.0 means vocal commands, digital services and software

With respect to product news, the range of low-cost igus robotics, conceived for the automation of medium-sized enterprises, continues to grow. ReBeL KID, the new small cobot with optional voice commands, will be available from May 2023. It’s one of the many solutions offered on the RBTX marketplace, in which customers can find over 350 automation projects, to take as an example and implement. With "superwise - Igus smart service", moreover, Igus combines an excellent digital service with smart plastics solutions. In addition, there’s the "kopla" software platform, thanks to which producer companies will be able to create their own configurations online and computation instruments.

Tangible sustainability

By 2025 igus intends to eliminate the climate impact of its production processes, in particular, thanks to a system that makes it possible to heat a factory using cooling water heated in turn by ink-jet printing machines, thereby eliminating the consumption of gas in the igus production site. It’s a technology that the company has decided to make available to the entire industrial sector, disseminating the MHRS (Machine Heat Recovery System) procedure developed internally.