The future of checkweighers is already here

The new “Blue HMI” user interface improves the efficiency of checkweighers with intelligent functions. It not only controls the machine, but transforms the final inspection into a new way of optimising production. Over to Minebea Intec.

With over 75 years of experience in the manufacture of checkweighers, Minebea Intec (industrial weighing and inspection technologies) has developed the perfect assistant for daily dynamic customer weighing and regulatory compliance activities. The new generation is based on a familiar and tried and tested design, combined with patented loading cells and a brand-new user interface, the heart of every checkweigher, with which the manufacturer has established new standards for the sector.

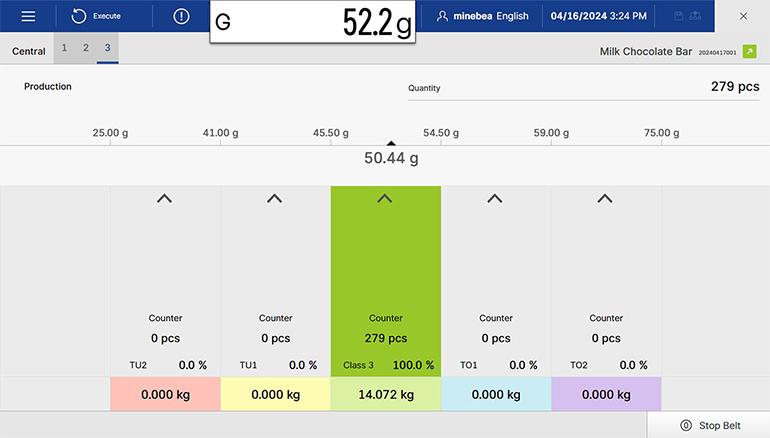

With the “Blue HMI” user interface, checkweighers can be configured, controlled, tested and verified for greater ease of use.

User interface with intelligent functions

Used in various industrial sectors, dynamic checkweighers detect weight alterations of products during the production and packaging process, to eliminate those defects and guarantee compliance with weight regulations and quality standards. Whether involving the acquisition of a new product, regulating line parameters or defining a batch report, the new Blue HMI user interface makes the work with checkweighers simpler and more efficient; designed starting from the experience acquired in high-technology devices in the field, the “menu-based” interface permits more rapid learning, clearly displaying workflows and managing data in a safe and flexible manner.

Blue HMI also offers new and expanded setting options for managing users and groups. With regards to the ergonomics of the entire system, all Minebea checkweighers, including the Synus®, Flexus® and EWK series, are now available also in a mobile display version.

Maximum control. Blue HMI allows for the advanced monitoring and analysis of checkweighers for a better control of quality and the optimisiation of processes. As Dr Thorsten Vollborn (Product Management Inspection & Digital Services Manager of Minebea Intec) explains:

«The operational unit displays the overall effectiveness of the system and other statistics based on current weighing results. It also has various logging functions that make it ideal for audits. And since checkweighers are often found at production end-of-line, the effectiveness of the integrated equipment provides a clear overview of overall efficiency».

All this is displayed on a dashboard or “control centre” using new widgets and diagrams. Besides checkweighers, the versions combined with the Vistus® metal detector support new workflows. In this case, the clear display improves the overall detection of extraneous objects, essential in many sectors.