D.C.M. – Packaging reference partner

2024 is a special year for D.C.M. (the sale trade and installation of paper folding and automation machinery), which celebrates 50 years of activities in the world of packaging.

Quality, innovation and know-how are the values that have always guided the company, driving it to develop increasingly cutting-edge solutions over the years with a constant focus on the world of packaging in different goods sectors thanks to successful partnerships and to a broad technological offer, able to meet the most diverse market needs.

A long-lasting collaboration with Kraus

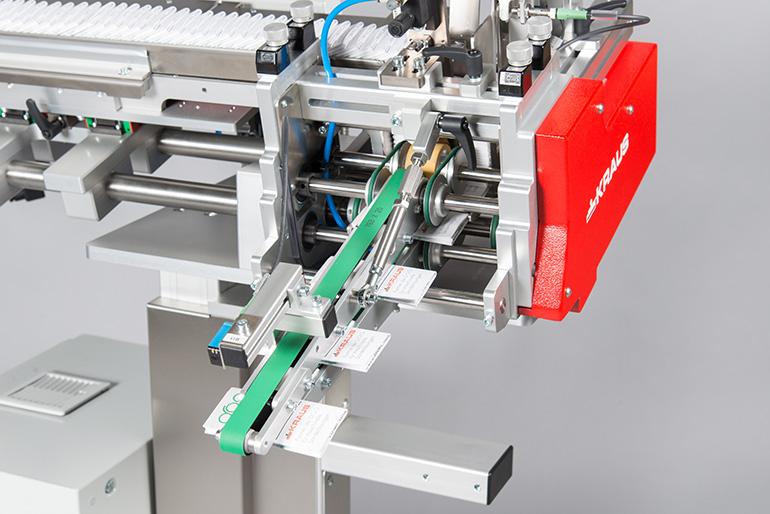

D.C.M. has been exclusive distributor for Italy of Kraus brand packaging solutions for many years. The German company is recognised as a European leader in the construction of sheeters and special lines. Product dispensing, labelling, transportation, inspection, serialization and coding are only some of the processes that these machines can handle at industrial speeds. From simple sheeters to accumulations and counting stations, from folding-gluing systems to the packaging of single-dose sachets, the range offered in partnership with Kraus manages to meet the needs of customers who are looking for greater productivity on their lines.

Labeljack, flexibility and speed, ready for industry 4.0. Among the latest proposals for special processes, in particular for labelling, the Labeljack system stands out, characterised by a high cycle speed, predisposition to industry 4.0 and flexibility in the management of labels of various formats, all pluses about which D.C.M. chairman Alessandro Casiraghi comments:

«Among the numerous processes developed for special lines, the labelling systems play a key role, especially regarding the level of personalization that they can offer. Through Labeljack’s integrated control, it’s possible to define settings such as language, interface and memory of the label format. Operating and warning messages are visualised on the multi-touch colour display. Finally, easy handling and maximum precision and dynamics are guaranteed thanks to its exclusive blocking mechanism and simplicity of use ».

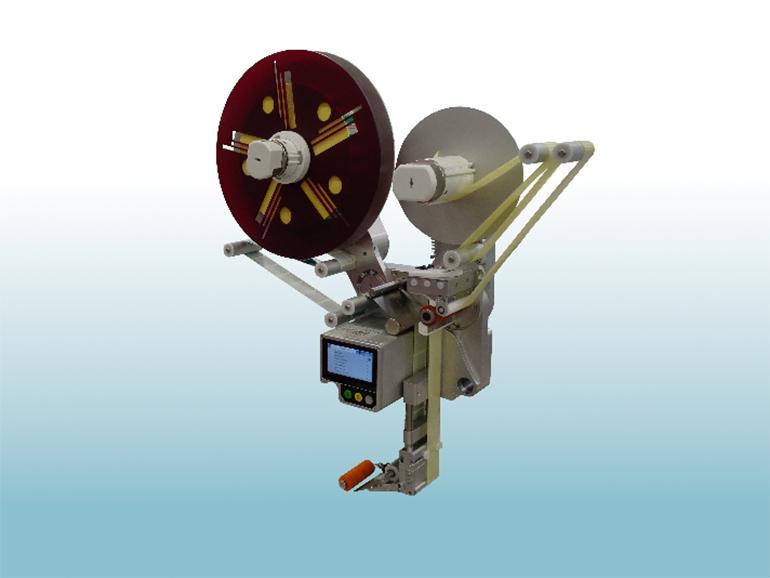

An integrated system for 100% printing control. The system for analysing printed materials with finishings, reliefs, holograms and embossing typical of luxury packaging is one of D.C.M.’s most recent developments, in collaboration with Kraus and with Endeavour–EyeC, offering highly advanced inspection technology. Starting from a friction sheeter, the products are separated and placed on the suction conveyor that transports them under the monitoring vision system. This makes it possible to check 100% of the samples, automatically discarding the defective ones. In contrast with an analogous system installed on the fold-and-glue machine, this one doesn’t damage the samples, allowing them to be reprocessed, if necessary, with different tolerances for sorting and second choices. At the end of the process, once the defective ones have been discarded, compliant products are collected with scale collection systems.