Etipack | Cosmopack 2022

For the return of Cosmopack, Etipack proposes some of the best solutions for the cosmetics and beauty sector. Know-how and experience have allowed the company to respond to different needs and critical issues, designing innovative and tailor-made solutions.

Those who work in Etipack know very well that, in the cosmetics industry, the uniqueness of the label increases brand recognition, but it is the perfection of its application that increases the competitive advantage of the product. This is why Etipack combines the design of tailor-made labelling solutions and systems with the building of customer relations in order to meet the customer's needs.

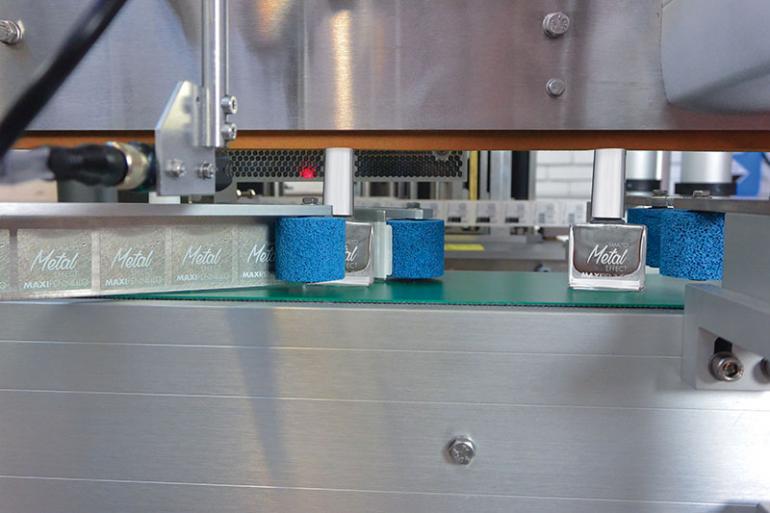

The protagonist of labelling machine projects, especially for cosmetics, is precision: in fact, it is necessary to work on products with small surfaces. The application of labels therefore becomes a precision challenge that requires the use of innovation. Every day, the R&D department studies new technologies that give added value to the systems, thus achieving an ever greater potential. This is why innovation and precision are so closely linked.

Over the years the challenges have been many: the type of label to be applied, the diversity of surfaces to be worked on, the quantity of products to be labeled or the management of operational functions. Some of the solutions proposed were, for example, the multiple labelling system for an important enamel manufacturer customer, capable of labeling elliptical bottles not only on the front and back of the product but also on the cap in a single system designed for small packaging.

Or what was done for Phytosolba-Alés Groupe, which was looking for a system to counteract the problem of limited space available inside the plant, which would have limited access to the system. In this case, a solution was designed to manage double-sided labeling from one operator side only, contrary to what is usually done.

A word from… Marco Parretti, CEO of Etipack

General supply difficulties, significant increases in freight rates, raw material and energy prices: how are you coping with these issues?

In recent years, despite the critical issues due to the pandemic period, Etipack has continued to develop and work on the innovation of its machines and to respond to every challenge posed by the market. For example, the recent increase in the cost of steel and aluminium castings has forced the company to increase the prices of its machines but, in order to meet the needs of its customers, Etipack has decided to reduce its margins, thus containing the surcharge due to the increase in the cost of raw materials and energy. The situation in the electronic components sector deserves a separate discussion, where the speculative behaviour, which has been going on for some time, is particularly evident: Etipack is trying to deal with these situations by working side by side with its partner suppliers, who are also victims of this situation.

|

Etipack S.p.A.

|