ItaliaImballaggio’s view of Cibus Tec 2023: M.H. Material Handling

Food safety, environmental sustainability and work safety: these are the areas developed by M.H. Material Handling with a variety of solutions linked to its core business, that is, internal handling systems and, in general, connection technology between packaging machines and accessories to cover internal handling needs both in terms of layout and in terms of transported product.

Luca Fontana, CEO and marketing manager of the company talked to us about this:

«In the show, we presented the SVn-Bare light spiral (the result of the collaboration with Ambaflex), which makes it possible to free up space in the work environment, creating operator passageways and increasing the ergonomics of the line, with an overall improvement in the passive safety of the plant.

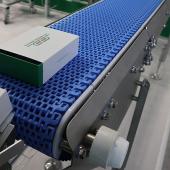

This is all achievable with an extremely competitive investment. For risk-free handling and transport, we offer the AIM (Active Integrated Motion) sorting system developed in collaboration with Intralox, in order to satisfy the need to better manage new, light and thin packages on automatic lines and which also makes it possible to develop deviators with an innovative technology, gripping the products from below, thereby eliminating the risk of jamming. Finally, again relating to the theme of food safety, M.H. has developed Sani-Flex Ideal, the Hygienic Design sanitizable conveyor belt, specifically designed for processing meats, fish and poultry.

Our business is directed, in fact, particularly at the fresh food sector and at the sustainability challenges that are affecting the world of packaging, in which the central issues are food safety, shelf-life, and the reduction of food waste ».