NUPANO: an open and intuitive platform

Open standards and ease of management of the Nupano platform: enabling technology developed by Lenze, which makes it possible to equip series machines with tailored solutions, thereby optimising production also from an energy point of view.

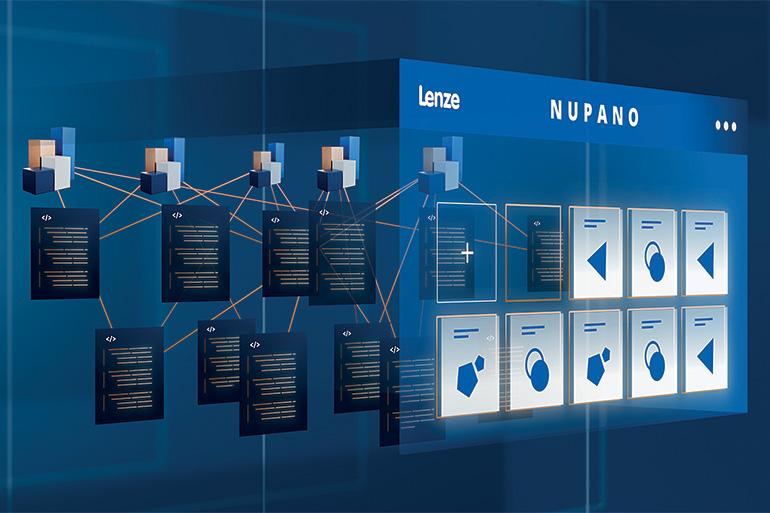

Machine manufacturers are looking for new ways to make profits. To stand out in an increasingly competitive market, they offer additional digital services, but often do not possess the necessary resources and know-how. Lenze can provide a concrete solution to this end: the new NUPANO open automation platform, which offers a space for digital innovations on machinery and systems, besides access to new business models, without the user requiring any preliminary information technology (IT) expertise.

NUPANO offers machine producers the means to fully exploit the opportunities that derive from the combination of operating technology with the infinite possibilities of modern IT, gaining access to new economic advantages. Lenze’s platform guarantees, in fact, open standards and ease of management, and adopts the highest level of security to safeguard industrial know-how.

Access to the machine through the digital twin

A crucial factor of the success of this open automation platform is that it permits other users, who lack the specific IT expertise, to use the applications and even to implement and update them.

For this reason, the developers of the platform have paid particular attention to user experience (UX). On NUPANO, the customer finds both the application and an overview of their machines in the form of digital twins. With a simple drag-and-drop, the user can unite the two worlds of OT and IT. As explains Paulin, Lanze’s manager responsible for the new automation technology: «We have to install the software in a simple and efficient way in at least 1,000 machines per year, otherwise we wouldn’t provide any added value to our customers». The applications are then transferred to an industrial PC through the system’s digital twin. From here, the applications are performed by Runtime NUPANO: this is the point in which NUPANO and PLC Runtime join. The effectiveness of the technology developed by Lenze has received extensive positive feedback and the first customers are ready to use NUPANO, giving continuity to their applications or developing new ones.

TALKING OF LENZE

Over 75 years’ experience for Lenze, world leader in the industrial automation sector, which provides technologies for designing modern and sustainable production systems. Thanks to key skills in electrical design, advanced software and with a flexible automation platform, it supports its customers in the digitalisation of systems and in the optimization of machines’ life-cycles, obtaining an increase in energy efficiency and a consequent reduction of costs. It also offers high-quality mechatronic packages, complete systems (hardware and software) for the automation of machines and digital services for business. With registered office in Aerzen (D), the Lenze Group employs 4,000 workers throughout the world and is present in 45 countries. In the 2021/2022 tax year it generated a turnover of 830 million euros.