Marchesini Group: New vial track & trace line

Marchesini Group offers proof of its skills in creating complete track & trace solutions for pharmaceutical products in the name of flexibility and reliability through the new and unique line for vials produced for a renowned multinational enterprise of the Pharma industry.

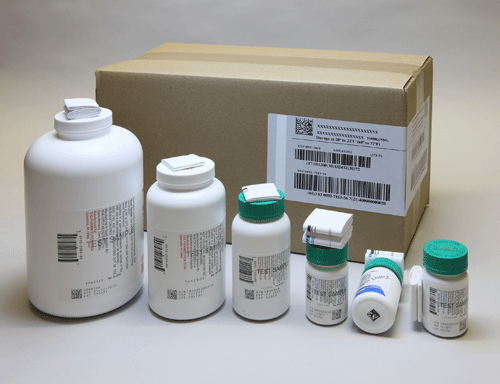

The line, which is a model of how to serialize pill containers packaged directly in cases without first putting them into cartons, comprises a rotary labeller model RE 302 and a top-loading casepacker model MCPV 850; both machines have their own traceability system that continuously monitors the products throughout the entire packaging process. This line has special camera vision systems, installed on the vial labeller and on the casepacker, which monitor the products from the initial coding phase of the individual bare vials, through to the palletization phase of the filled and sealed cases. The machines operate with “Fail Safe” logic to ensure zero errors. Let’s take a look at the details.

Automatic rotary labeller RE 302 1T. The vials infed from the machine upstream are already filled and capped and are transferred onto a conveyance system made up of two vertical belts with adjustable opening width on the inlet of the labelling machine; these belts hold the vials by their sides while an inkjet marker prints a unique 2D service code on their bottom, which is also verified immediately by the first camera.

On the inlet of the main vial carousel, the second camera acquires the 2D service code printed previously on the bottom and sends the start signal to the shift register, which acquires the position of each vial on the carousel.

The label, still on its film, is printed by the labelling unit and the unique 2D code is verified immediately by the third camera. The code comprises a product identification code, batch number, expiry date, unique serialized number and all these data repeated also in readable digits. The camera grades the print quality of the serialized 2D code and scans the readable digits with an OCR/OCV system. The fourth optional camera reads the Pharmacode on the labels to identify them accordingly.

Subsequently, once the label has been applied on the vial, the fifth camera scans its unique serialized 2D code and, by means of the afore-mentioned shift register, associates it with the unique 2D service code printed on the bottom. This operation is ensured thanks to the fact that the machine is able to turn the vial conveyance devices so that the 2D code on the previously applied label appears in front of the camera lens: this is an essential feature of the RE machine series. Each unique serialized code printed on the label, graded and correctly applied, is consequently associated with the service code, printed on the bottom of the containers: by matching the two 2D codes, it possible to trace the vials in the casepacker downstream.

Top-loading casepacker MCPV850.All the compliant vials outlet from the RE302 1T continue through to the infeed into the casepacker MCPV 850. Here, they are grouped into layers on a glass surface where the control station is located, with the sixth camera; this unit simultaneously reads all the unique 2D service codes printed on the bottom of the containers of each layer.

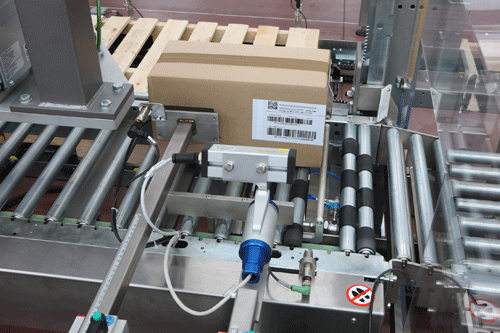

The unique 2D service codes provide an exact match with the unique serialized 2D codes associated with them on each vial so that they can be acquired. A pick & place unit picks up the layers of containers and places them inside the case, which is subsequently sealed with adhesive tape. At this stage, the full and exact identification of the vials inside each case is known. A label is then applied on the corner of each case, on which a unique serialized code is printed in real time, which is associated with all the unique serialized codes of the vials inside the case. The seventh camera verifies this code printed on the label of the case. This operation starts the aggregation of the individual products inside the cases.

To end, each compliant case is picked up by the pick-up arm of the Gigacombi unit, which places it on the pallet according to the pattern set and saved on the machine’s PC. At this stage, the aggregation of the individual cases on the pallet continues, applying another label on the corner, which is verified by another camera, and on which a unique code will be printed in real time that is associated with all the unique codes of the labels of the cases.