Xplanar, the turning point in motion

Unprecedented freedom of movement and flexibility, integrated in a PC-based control architecture: innovative and futuristic, Xplanar is an independent, magnetically levitated trolley transport system from Beckhoff.

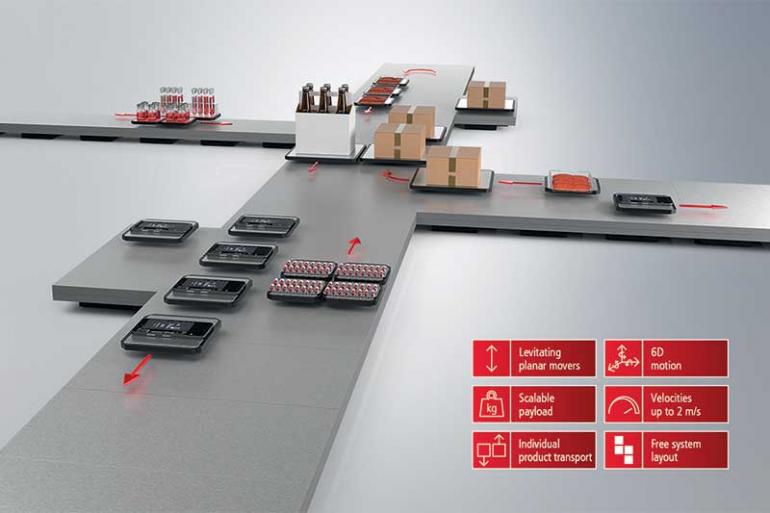

The independent trolley conveyor concept developed by Beckhoff with XTS has evolved further with the introduction of XPlanar, a revolutionary magnetic levitation handling system that marks a decisive breakthrough in motion technology.

The concept on which XPlanar is based is that of moving “n” movers independently, by means of fluctuation, thus eliminating any physical contact with guides or supports.

This takes place thanks to an XY reference plane, composed of a series of interconnected electronic “tiles”, on which a field of electromagnetic forces is developed, capable of supporting pallets of objects.

Designed primarily for use in packaging, assembly and intralogistics applications, XPlanar’s movers are not bound to any pre-established mechanical structure (such as rails, tracks, etc.) and are able to proceed on alternative and dynamically reconfigurable paths. The absence of friction makes the system quiet and immune to wear and tear issues that can create unsanitary conditions.

Available in multiple construction options - glass, stainless steel or plastic - XPlanar can be used in a variety of environments considered “difficult”, such as clean rooms, food production departments and pharmaceutical workshops.

Different configurations available

XPlanar offers different types of mover (floating plates): from size 95×95 mm up to size 275 x 275 mm, which can be used to handle loads from 0.4 kg up to a maximum of 6 kg.

The floating plates can be moved in the two X-Y dimensions with speeds up to 4 m/s and accelerations of 2 g, ensuring a positioning repeatability of 50 µm. These properties are complemented by new 360° rotation capabilities that, thanks to the full integration of the XPlanar system into the PC-based control architecture, are available through a simple software update.

XPlanar movers can thus rotate around their own axis during levitation, in selected positions. The rotation, which occurs in a programmed manner (with frequencies of up to 10 Hz), makes possible a variety of innovative applications, such as mixing liquids or 360° inspection of objects. In addition, the movers can leave their rotational positions with an orientation that can be changed in 90° steps, so that, if necessary, the transported workpieces can be aligned in accordance with the required configuration for the subsequent processing steps.

In addition to moving freely in the X-Y plane, the plates can raise and lower vertically (Z axis) by 5 mm, tilt by 5° and rotate, thus offering 6 degrees of freedom. An optional integrated weighing function completes the advanced features.