Identifying the product and guaranteeing its integrity

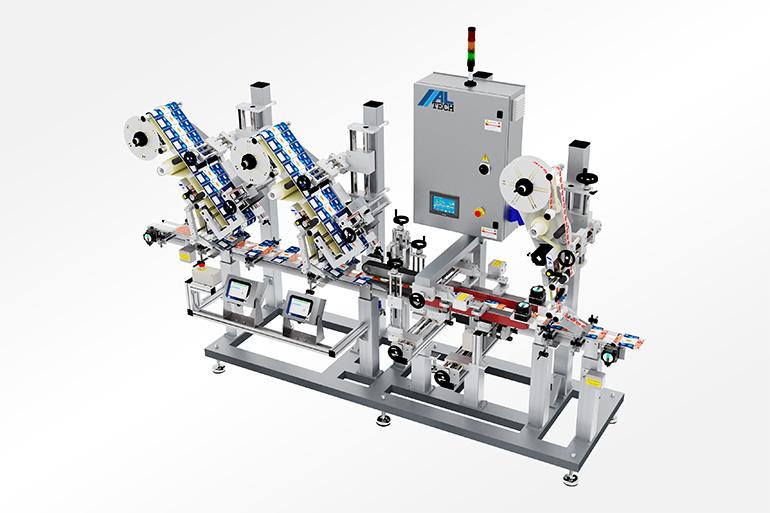

Altech offers a “D-wrap” labelling system for an important English seafood operator.

Recently completed, the installation is based on the innovative “D-wrap” labelling system for trays - in this case of fish – designed to wrap packages on four sides, starting from the top and then continuing laterally and then on the underside. This is a type of labelling that simultaneously performs multiple functions, becoming an informative, decorative and sealing element. Altech’s system, with a speed of up to 100 packages per minute, carries out the application and folding operations smoothly with moving trays, suitably spaced by the input timer.

To further increase the system’s productivity, the machine is equipped with double labelling heads in non-stop configuration, that is, they intervene alternately as soon as one of the two runs out of labels, so as to guarantee continuous operation without interruptions.

In addition, to affix the variable data required on food products, the system is equipped with two intermittent thermal transfer markers, mounted on each of the two heads. The system is completed with a third labelling head, positioned downstream of the D-wrap labelling machine, dedicated to the affixing of promotional labels, which can be applied in any position on the top of the tray.

Hygienic design and people-centred

The system’s structure is in stainless steel, appropriate for food contexts, and is equipped with an IP54 electrical panel, also in stainless steel. The PLC management controller, with a touchscreen control panel, makes it possible to check all the functions from a single workstation and to memorise the operating parameters within specific recipes, making the start-up and format change operations simple, repeatable and particularly rapid.