The right blend of technology and flexibility

Thanks to the collaboration between BipGroup and Eurocoding, an efficient and customized GoDEX-branded labeling system has improved the productivity of the coffee pod packaging process at Italfoods srl in Villar San Costanzo (CN).

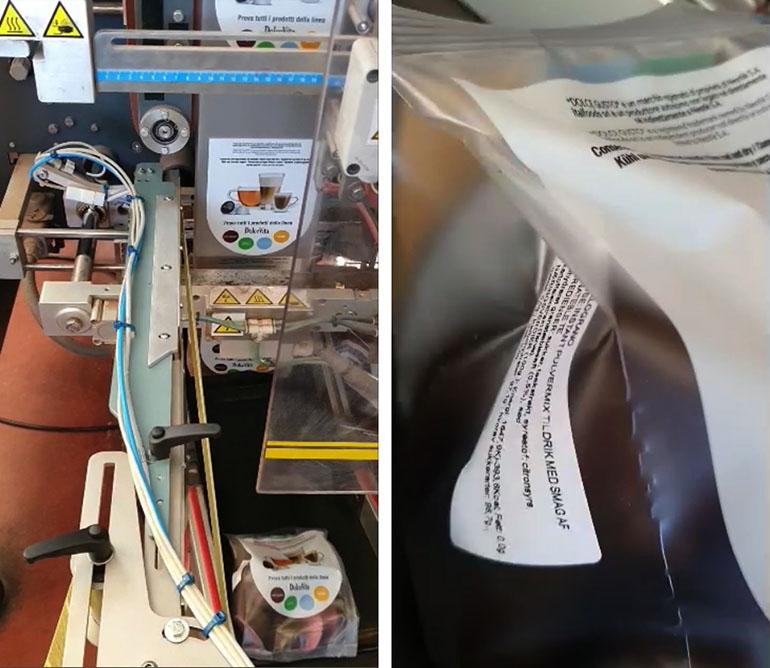

Bip Group-which has long been developing software and hardware products dedicated to transport, logistics and marking management-recently proposed and installed at Italfoods srl (a major manufacturer of coffee capsules) a print-and-apply system that has significantly improved the packaging phase of espresso machine pods. All this by leveraging the first-rate consulting service provided by Eurocoding, for which Bip Group is a reseller.

Problem solving

Italfoods was asking to speed up the labeling of the bag in which the capsules were packaged, an operation that until then was handled manually by two employees. And the problem was not an easy one to solve: «It could have been a bitter coffee - comments Claudio Carrieri, administrator of Bip Group - but we were able to enjoy it to our satisfaction, thanks in part to a… correction».

After a careful cost-benefit analysis, he opted for GoDEX’s AG 2000 applicator. Indeed, GoDEX modular applicators are among the most cost-effective printing and labeling solutions, simple to use and easy to integrate on lines by virtue of their exceptional flexibility. And it was this special feature that further motivated the choice.

Bip Group therefore approached Eurocoding for information on the features of GoDEX products and, more importantly, whether they could be adapted to the customer’s packaging line. And since Eurocoding’s modus operandi towards its resellers is not limited to a simple distribution and sales relationship, being the true partner it is, it offered ad hoc advice, confirming and approving the solution proposed. Bip Group was thus able to proceed, focusing specifically on two packaging lines and working on customizing the applicators.

The two GoDEX systems-one per line and with modifications made by BipGroup to allow them to be positioned in the space allowed-now print and apply labels with data in the original language of the different countries to which the products are to be exported. More precisely, one system works on moving packages and, by means of a special piston, applies the label directly on the film; the other operates on the stationary package and applies the label by blowing, i.e., not directly with the machine movement on the surface of the bag but by means of an air blow, at a distance of 1 cm from the package.

Each process is carried out with 15-20 beats per minute. In combination with the EZ series of printers, GoDEX AG2000 proved to be the ideal system for automatically printing and applying self-adhesive labels to moving items.