Revolution in coding and marking systems

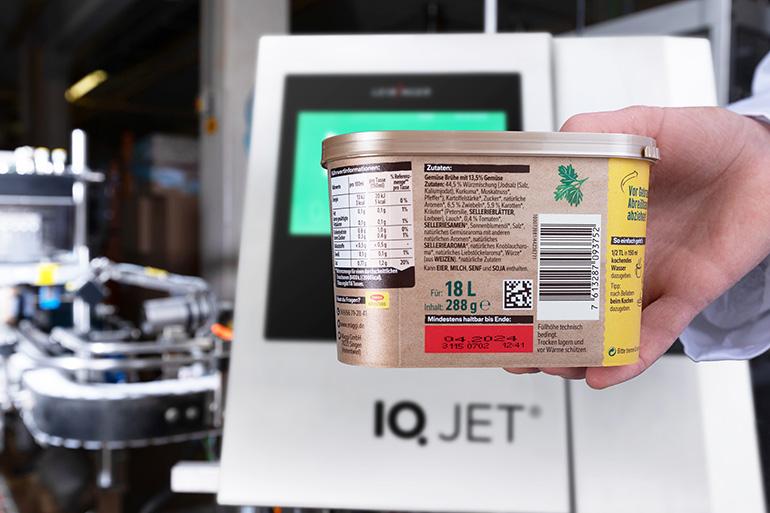

Leibinger presents the IQJET printer, able to overcome the critical issues of traditional CIJ systems. Installed at Maggi Group’s Singen factory, it ensures high-level performances with reduced consumption, ease of use and no maintenance for the first 5 years of its life.

Coding and marking systems are an indispensable part of the production line, despite being only one of the elements that compose it. Although apparently simple operations, many conventional coding and marking systems inserted into a real production context do not live up to expectations, missing the objective of continuity of operation and reliability, essential characteristics for this type of operations.

Repeated downtime, long start-up or retooling times, insufficient flexibility during production changes, are just some of the problems leading to repeated machine stoppages. There is an alternative to these problems and is offered by Leibinger with its new IQJET coding and marking system.

Environmental, operating and economic sustainability

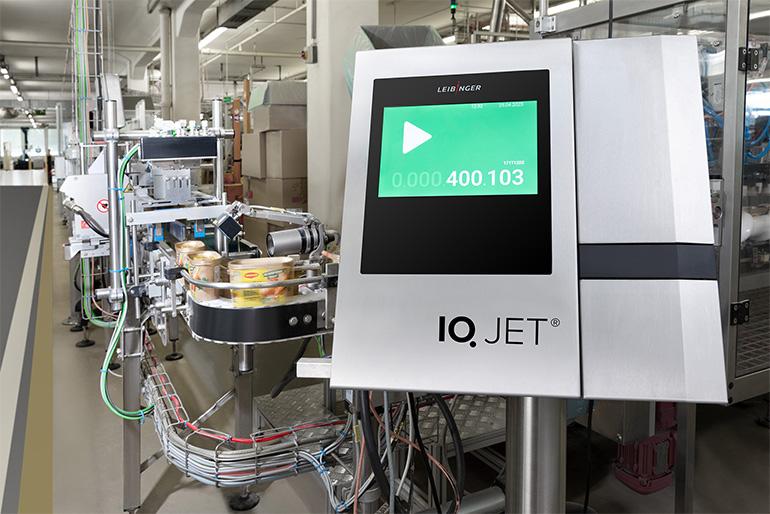

Presented in May, IQJET is a new generation of smart coding and marking characterised by sustainability, maximum reliability and significant savings on operating costs. IQJET offers plug & print performances, reducing production times to a minimum, in the total absence of maintenance for the first five years of the product’s life.

«Once connected, the IQJET begins to function immediately and perfectly, needing virtually no operator intervention while running» declares Simon Keller, Technical Group Manager, Packaging Deli/Tainer division of the Maggi Group. «In addition, the system does not require cleaning operations and cartridge change is really ergonomic and easy».

The problems of traditional systems

The most common marking systems for printing variable data such as best-before dates, codes, series numbers, etc., are continuous inkjet (CIJ) printers, characterized by great flexibility.

CIJs are suitable for almost all surfaces, forms and materials, coding is contactless, they allow for simple integrative operations and are in general safe for the environment and for people, and no protective equipment are necessary.

The inks, moreover, dry quickly and are suitable for almost all production environments and applications. In all events, among the disadvantages of conventional CIJ printers, there’s the need for regular cleaning, usually at every start-up and with inevitable and frequent production stops. In the event of lack of use, moreover, the ink dries, obstructing the lines, lengthening downtime and often producing inaccurate print images at first startup.

Leibinger’s solution: no downtime and a unique design

Leibinger’s CIJ marking systems take a significant step forward in overcoming the classic problems of the sector, as Christophe Lopez, Leibinger CCO underlines:

«A CIJ does not require any routine cleaning since the technology underpinning the system is completely different from traditional models».

Leibinger’s CIJ systems, in fact, have a fully automated nozzle sealing technology. Whenever the printer is not in operation, therefore, the ink is sealed in an almost completely hermetically sealed circuit in which, however, the ink continues to circulate. This makes it possible to avoid blockage of the ink or cases of drying, avoiding the need for cleaning and drastically reducing downtime.

«This technology is unique on the market - Lopez continues – and the hermetic and fully automatic pressure nozzle sealing, in fact, is offered exclusively by Leibinger».

IQJET begins to function immediately after being restarted, providing a constantly high print quality, regardless of the environmental conditions, thanks to the temperature control and constant ink viscosity.

Consumption reduced by 50%

Another advantage of the hermetic closure technology is that no solvent is consumed during the print pauses. In addition, the new coding and marking system collects the solvent that evaporates during operation and reissues it into the system. This makes it possible to consume up to 50% less compared to conventional CIJ systems (2.7 ml of solvent/hour against 6/10 ml/hour). This means that based on three work shifts, for a total of 6,000 hours per year, the annual saving is 43,800 ml of solvent.

Another point of strength of the IQJET printer is its ability to avoid waste. Traditional coding and marking systems, in fact, require the replacement of cartridges also when they still contain 10% ink, which has a negative impact both on the environment and on business costs. Conversely, the IQJET allows for complete emptying and, given that the cartridges are made in made in mono-polyethylene, they are also easy to recycle.

There are also advantages from an energy consumption point of view: the printer consumes only 36 Watt, confirming its status as most efficient on the market.

Integrated smart operation

With IQJET, Leibinger sets a new standard also with regards to the smart integration of plug & print operations, thanks to the multiple interfaces, including OPC UA, and to an integrated PLC (programmable logic control).

«The presence of a cutting-edge HMI with 10-inch touch display and an intuitive drag-and-drop system makes it extremely easy to use: in addition, no operator interventions are necessary during its operation» Keller once more pointed out.

Lasting quality

The most sustainable products are those which have a long life-cycle. Leibinger CIJ printers are produced exclusively in the German factory, in which over 85% of the production is vertically integrated.

Here, quality control and the use of components highly resistant to wear are the main focus of the entire production process. Thanks to innovative design, the IQJET printer does not require maintenance during the first five years of life, reducing operating costs and machine stoppage times (it’s not necessary for example, for the main pump to run continuously during printing operations).

«Producers looking for efficiency and reliability will greatly benefit with IQJET. In Maggi we also appreciate the fact that our employees now have more time to focus on essential aspects, such as the safety and quality of the product» Keller concludes.

NOTE. Leibinger-brand products are distributed exclusively in Italy by Sis.Ma, the company based in Casalecchio di Reno (Bologna).

(photos: Leibinger)