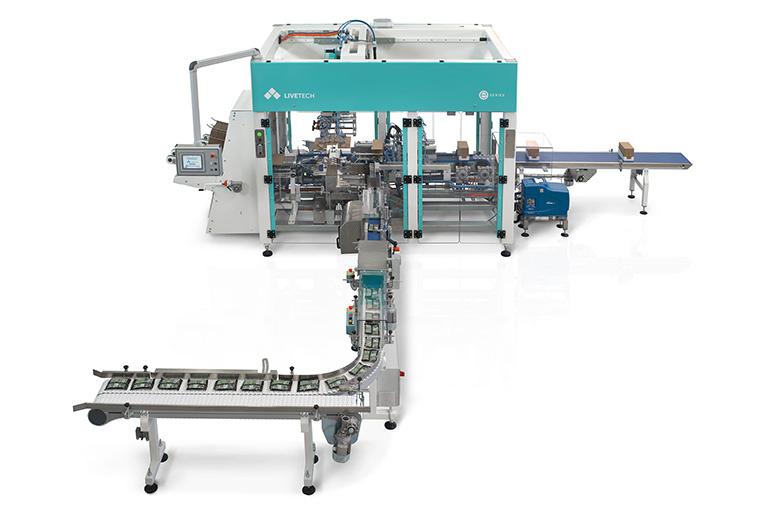

A robotised island that combines ergonomics, compactness and sustainability

Livetech’s LWA-TH robotised island is the perfect solution for the packaging of pillow bags, square bottom bags, doypacks, stand-up pouches and cases inside bottom-and-lid type boxes and/or wraparound type boxes.

Live-Tech at Interpack, Hall 3/B47

The machine is one of the top models of the “e SERIES” line and is based on the concepts of efficiency, effectiveness and essentiality. These characteristics make it extremely efficient also from the point of view of energy consumption and, consequently, environmental sustainability. Compact and ergonomic, the LWA-TH makes it possible to form, fill and seal boxes inside a single machine, eliminating the need to install a number of separate systems to carry out the same functions.

Versatile and intuitive technology

The machine makes it possible to make the box an integral part of the product’s overall image, optimising, at the same time, costs and functionality. The packaging fully protects the products during handling and transport and, in a few seconds and without the use of tools, easily transforms into a display unit to be placed directly on the shop shelf. Thanks to these characteristics, the LWA-TH systems have enjoyed considerable success with sector producers, especially in the world of pillow bags and square bottom bags used for packaging sweet and savoury products of various types, such as sweets, chocolates, snacks, etc...

Internationally renowned customers have been using LWA-TH for years to pack their products in single-row or multi-row formats, and also in multi-layer arrangements. Management of the machine is easy and intuitive, both for line operators and for maintenance staff. Further to request, the machine can be fitted with a series of highly innovative options able to increase its technological content. These include, for example, the automatic format change systems which make it possible to completely automate a large part of the operations required for passing from one format to another, with minimum intervention on the part of operators and with numerous advantages: reduction in format change times, reduction of the possibility of error, greater control of the operations performed, and greater security.

Another much appreciated accessory is the vision system inside the machine, composed of a repositionable mobile video camera able to transmit live images to a remote external video station.