More productivity in box forming

Operations and efficiency

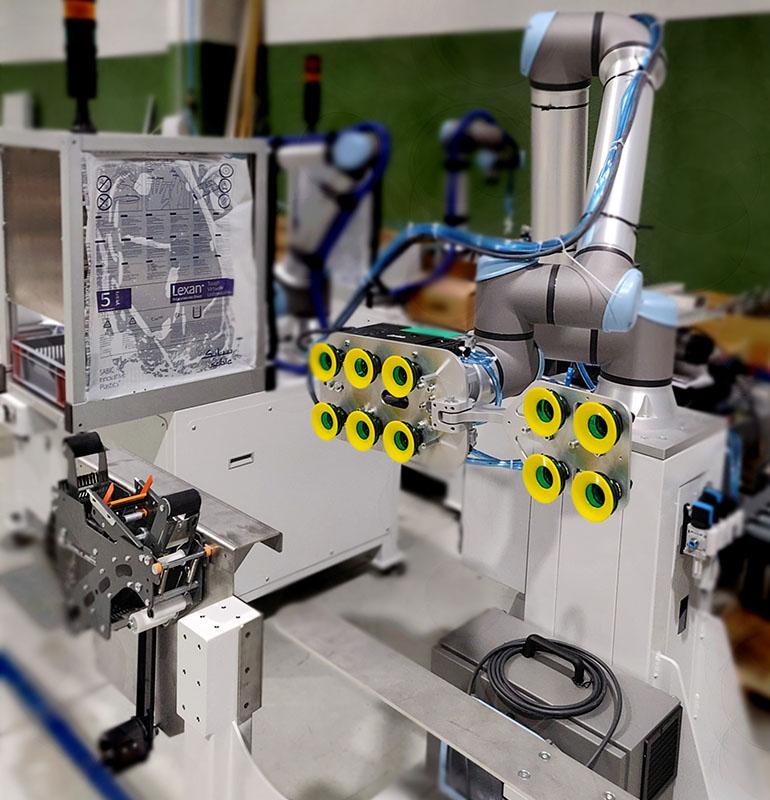

Cob-Solution’s system, the CoBox Erector, was installed in the customer’s logistics department to relieve the operator from the repetitive task of forming-where, in particular, the Piab gripper intervenes-and taping boxes. Fully configurable and equipped with remote assistance, the plant offers the possibility of handling different box formats thanks to its double bay design (the maximum capacity of each bay is 40 pieces with a cardboard thickness of 5 mm) and is capable of forming and taping 4 boxes/min, picking up the knocked-down box directly from the warehouse. Once formed and taped, the boxes are deposited on a roller conveyor placed above and, by gravity, descend onto the line, where an operator fills them with the products ordered online: drugs, parapharmaceuticals, supplements, and antiparasitics venfor small and large animals are fed into the line from an automatic warehouse. After filling, the boxes are closed and taped by the same CoBox Erector, to be then checked by the operator, automatically labeled, and shipped.

Critical issues overcome and benefits achieved

Even in the Cob-Solution case plant, Piab demonstrated its reliability by sizing and supplying a complete vacuum gripping system, including avoiding the use of a product mix that generally does not facilitate the customer’s procurement of spare parts.

The project involved the use of B-XP bellows suction cups and piCOMPACT®23 SMART, a configurable vacuum ejector developed for robotic handling applications (see box) As explained by Federico Caroppo and Matteo Barbieri, respectively CEO and Technical Manager of Cob-Solution, in particular, the most complex problem solved thanks to Piab’s intervention was related to the dimensional and weight difference of the box formats to be handled (which are now handled with reliability and precision).

In this sense, the porosity and stiffness characteristics of the cardboard were also a further critical element to be carefully evaluated. Thanks to Cob-Solution’s automated system, Rao Farmaceutici has seen a 30 percent increase in productivity and is considering its introduction at other of its plants.

Focus on PIAB Technology

- B-XP bellows suction cups, ideal for uneven and porous surfaces such as cardboard, are made of DURAFLEX®, an anti-alalone material developed by Piab that has the elasticity of rubber and the wear resistance of polyurethane.

- piCOMPACT®23 SMART is a configurable vacuum ejector developed for robotic handling applications. It integrates 2 solenoid valves for vacuum and blow-off management, a vacuum switch, and a number of sophisticated software functions to reduce compressed air consumption and simplify robot installation and programming. It has an optimized design for maximum reliability, versatility, high flow rates, and short cycle times. It is based on Piab’s COAX® vacuum generation technology, which minimizes energy consumption while providing safe and fast gripping due to its high initial flow rate.