Created to offer solutions

We focus on Servotecnica and its most innovative and recent proposals regarding linear actuators: designed to be integrated on automatic packaging machines, they guarantee manufacturers and end users handling processes which are safe, long-lasting and efficient, to the advantage of productivity.

Luciana Guidotti

40 years of history: it’s certainly a long time, but has served to consolidate Servotecnica’s reputation in the motion control market.

In recent years, the company (with headquarters in Nova Milanese, just outside the Lombardy capital) has experienced a sharp acceleration, equipping itself with more modern tools in order to best plan growth strategies and ensure customers the best service possible.

Together with the traditional activity regarding the distribution of industrial automation brands, Servotecnica has developed and manufactured own-brand products (in particular, slip rings and micromotors) that are marketed both in Italy and abroad through a network of specially-created distribution networks.

«Ours is an evolution that maintains the mission of its founders (Emilio Bistoletti and Adriano Salgarello, Ed.) in “providing solutions” - sums up Sabrina Bistoletti, Sales Analyst and Communication Manager of the company - thanks to a vast range of solutions, in which distributed and own-brand products can be easily integrated. The final aim remains, in fact, the offer of a quality service to customers, which we support with expertise in the management of projects, designing the most suitable automation solutions for their real application needs. This is possible thanks to our decades-long history - concludes Bistoletti - which enables us to offer tailor-made solutions in different industrial sectors, both with regards to mechatronics and electromechanical components. Our strength is the combination of innovative technologies and the experience and expertise of our technicians».

The right actuator makes all the difference

If we narrow the field of applications to the packaging sector, the offer of servo actuators is emblematic of Servotecnica’s management and production “philosophy”. This was explained to us in detail by Lorenzo Protti who, after having acquired experience in the technical office, took on the role of Product Manager for a number of products and represented companies.

«Linear actuators are essential for certain movements on packaging machines. Where the movements require greater power, we offer the Exlar actuators (a brand that Servotecnica has practically always distributed and which has for a number of years become part of the American company, Curtiss Wright, Ed.), which guarantee a high operating lifetime and are designed for high-end machines in applications in which the speed of movement and elevated dynamics are the main characteristics to satisfy.

Servotecnica also offers, in addition, small and light own-brand linear actuators, designed to replace pneumatic cylinders. We offer, therefore, two electricsolutions to be proposed according to needs: Exlar actuators in the field of hydraulics, and Servotecnica-brand direct and tubular motors for pneumatics, also available for the pharmaceutical and food sectors. The coexistence of the two types of actuators on a packaging line, each intended for different stations, is not, obviously, to be excluded: the Exlar products, for example, on a cutting station, where the operations have a longer execution time; our products, for example, used to select defective pieces detected by a photocell on the conveyor belts».

“Never fail” Exlar

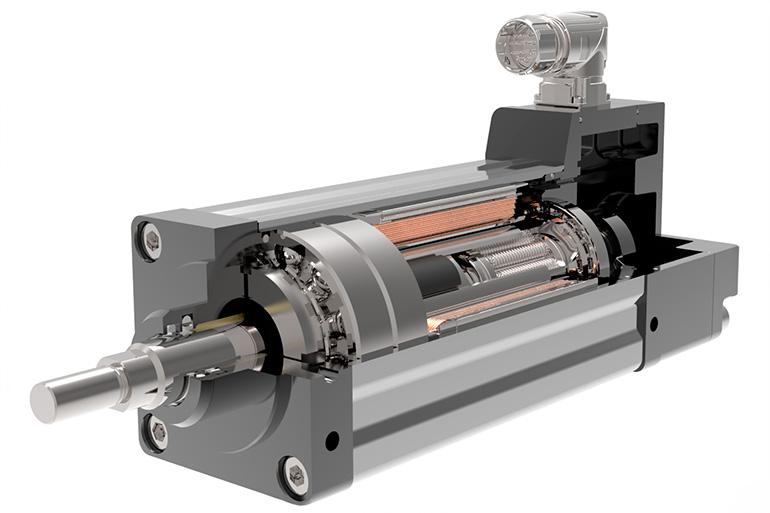

Exlar electric linear servo actuators offer a wide range of solutions able to always provide the maximum level of power and performance. These axles are built with a satellite roller screw, which can be with reverse geometry for versions with integrated motor or classic geometry for those with external motor, widely used in the packaging sector. The “integrated” category - so defined because the brushless motor is physically constructed around the lead screw, on which the magnets are attached - include the GTX and GTF series, which Protti focuses on.

«The actuators designed by Exlar have exploited an existing technology, that of satellite rollers, modifying it and improving it in order to satisfy the most demanding needs of the industrial sector. For this reason, despite attempts at emulation, Exlar products remain at the top of the range and guarantee superior levels of performance thanks also to the heat treatments of the materials used».

It’s a very tried and tested and, therefore, reliable solution that is used in high-performance machines or with heavy duty cycles for “never fail” applications.

«Another direct advantage deriving from the use of these servo actuators, Protti explains, is linked to the optimisation of consumption, resulting in improved energy efficiency: all the companies that are able to avoid installing in their lines a compressor for pneumatics or using a hydraulic control unit obtain an immediate energy saving. Irrespective of whether or not the axles are being used, in fact, the control units continue to consume energy to keep the oil under pressure, the pumps continue to work and electricity consumption increases as a consequence».

esides the benefits linked to the intrinsic technology, Servotecnica works on additional pluses, relating to the GTX and GTF series:

«First of all, I would like to point out that for this series of actuators, Exlar has sought to standardize the production, simplifying where possible the structure of the product, without obviously affecting performance levels, and thereby improve delivery times. In contrast to previous versions, such as the GSX/M, the GTX or GTF series has been designed with the European market in mind, and is made directly with metric threads which simplify assembly.

With regards to the KX actuators, with an external motor that can be provided by the customer, Exlar provides countless mechanical interfaces so that any type of engine can be assembled».

Considering the specific needs of certain sectors, Servotecnica offers, in addition, the explosion-proof version and the coated version specifically for the food sector. Simple, flexible, reliable: these are, in the end, the attributes that best define Exlar actuators, which Servotecnica capably promotes in Italy, contributing in this way to improving manufacturers’ competitiveness and efficiency.