Orange Lab: home of mechatronics

Orange Lab is the name of the showroom that B&R presented during a meeting dedicated to printing, in which 2022 economic data were illustrated and the functioning of a number of the key mechatronic solutions of the Austrian company were demonstrated.

M. Costanza Candi

Despite the raw materials and semi-conductors crisis that has affected international markets, B&R has set up its own supply chain, gaining further credit with customers, consolidating its position with sales volumes higher than before the crisis and presenting a trend of constant growth.

The think adaptive claim, therefore, goes beyond the boundaries of communication, expressing the character of the company which has confirmed its reliability over these recent years of the pandemic. Marzio Grattieri, General Manager of B&R Italia and Carlo Cuppini, sales manager, made specific reference to this fact during the day’s proceedings, offering a picture of the markets in which the company is present with its strong packaging vocation and particular attention towards the pharma&healtcare, food&beverage, plastics and power generation markets.

A new mass customisation concept

The current situation of highly fluctuating market dynamics redesigns the concept of mass customisation which, according to Cuppini, takes on an aspect of high modularity and scalability, combined with the capacity of systems to be reconfigured and reprogrammable, while at the same time maintaining intact the capacity for customization and high production volumes.

The shift from mass production to one that follows the demands of the market in a flexible way also responds to sustainability logics, regarding which B&R carries out actions going beyond public initiatives, affecting every aspect of production with a technical approach that focuses on the scaling back of consumptions, materials, and weights, alongside a more general reduction in waste, both in the production phase and in the management of the business.

Making room for applied technology

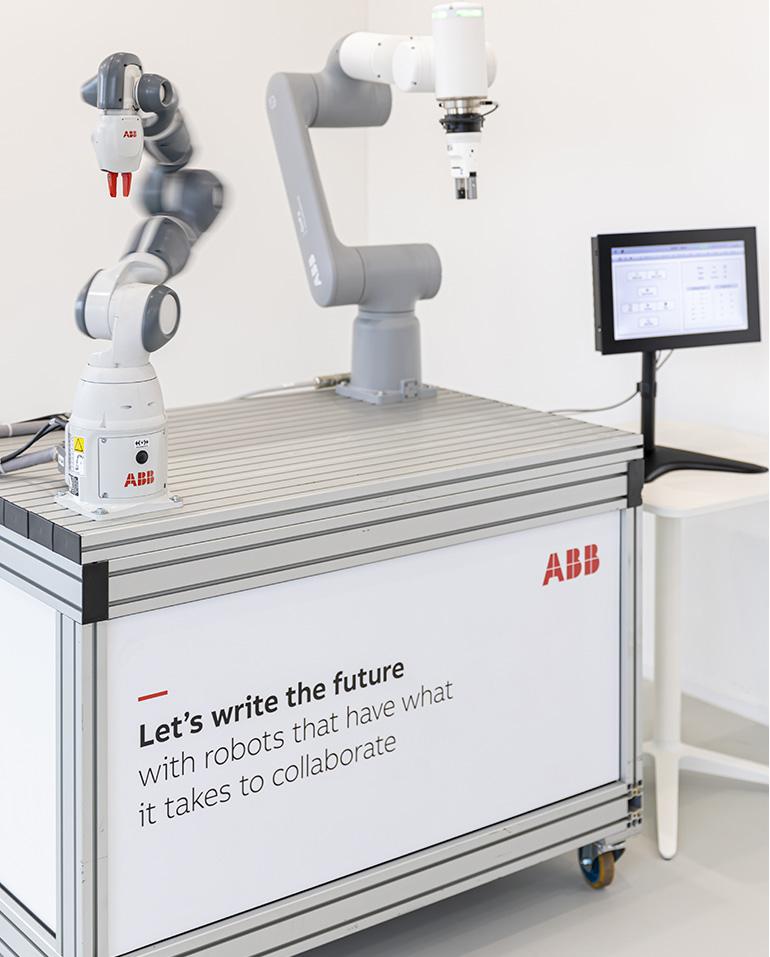

Inside the Orange Lab, which also performs the role of an academy, with spaces dedicated to training, B&R offers the visitor an immersive experience of its application solutions that start from the demotic management of the Orange Lab itself, entirely managed via B&R’s Mapp View.

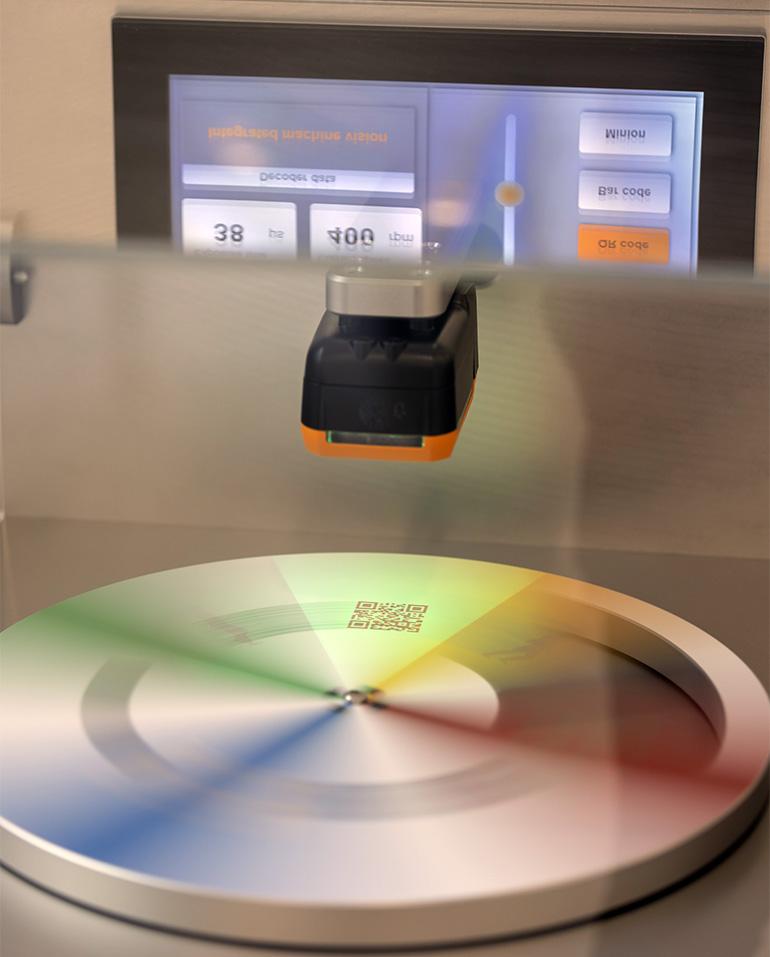

The web-based HMI interface, designed according to the logics of ergonomic gestures such touch keys or scrolling, offers the typical usability of mobile devices to make the user’s experience as easy as possible, to the maximum advantage of staff training times, and with regards to the use of complex production lines. The applications displayed in the showroom are examples of this, ranging from labelling lines for food and beverages to vision systems, PLC solutions for collaborative robots and modular solutions such as ACOPOStrack.

ACOPOS 6D certainly stands out as one of the most innovative proposals, a magnetic levitation system composed of a series of shuttles able to adapt to any variation in the weight, dimension and characteristic of a product handled on the platform and with a load capacity of between 6 and 14 kilos. It has recently been adopted by a cosmetics company for assembling elements that make up jar caps.

Among the particularly interesting technical proposals for packaging lines, moreover, the anti-sloshing solution stands out, a functionality available on all B&R’s mechatronic proposals (for transport), that is, ACOPOStrak, SuperTrak and ACOPOS 6D; this functionality makes it possible to contain the dispersion of liquids and powders thanks to a more fluid and controlled movement, reducing the consumption of product and materials for packaging, all to the advantage of sustainability and production costs.

Beyond formal sustainability

Sustainability for B&R is a strategy that includes many aspects of the company’s activities without forgetting the social aspect, as can be seen in the partnership with “Dolci Saperi”, the cooperative that employs people with disabilities for the production of excellent chocolate. From the management of consumption, to the development of solutions oriented to sustainability, from redesigning components from a green point of view to the selection of recyclable and recycled materials, from the reduction of volumes and dimension to the search for energy saving. Every aspect of the supply chain is reviewed from a sustainable point of view, summing individual measures in order to offer, overall, the guarantee of a significant reduction in emissions throughout the production chain.

A new development arrives precisely from the renewables world in which B&R is involved, in a new project shortly to be launched, which sees the production of new-generation photovoltaic panels capable of levels of efficiency that represent, for the design and materials, a veritable revolution for the photovoltaic market.

Finally, there will be many opportunities for public visibility for B&R in 2023, as pointed out by Silvia Mantica, Event Manager, announcing the official opening of the Orange Lab, planned for the summer, and participation at Interpack, SPS and Forum Meccatronica.