Claranor | Interpack 2023

H 13/ B20 | Pulsed Light and UV technology for packaging

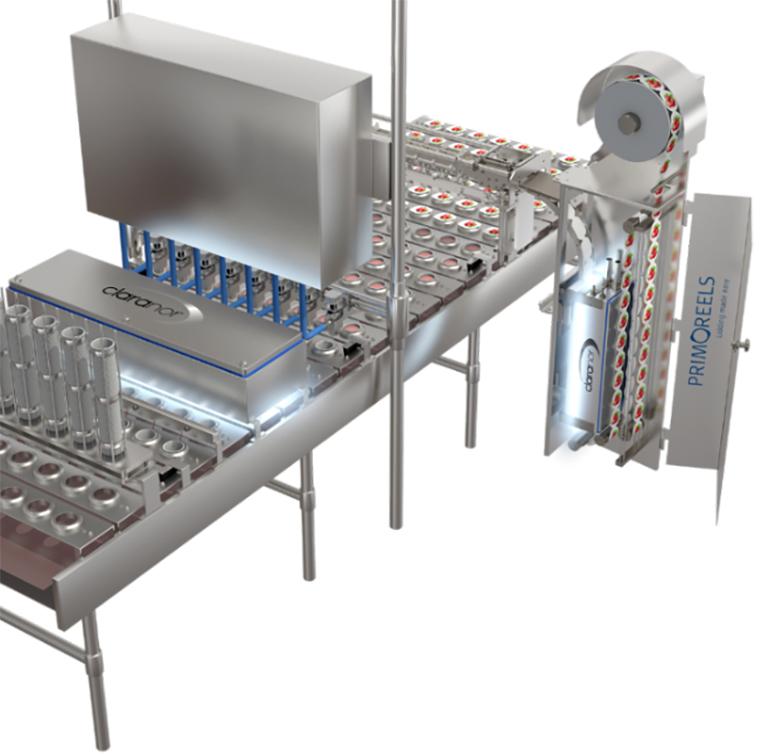

Claranor showcases a variety of solutions for filling, decontamination machines, pulsed light decontamination tools with significant savings in space, water and energy consumption. INNCAN & LID offers beverages and sweet condensed milk ultra-clean filling. Designed for the decontamination of metal cans and lids without water or chemicals, it avoids pasteurization tunnel and flaming. The compact equipment is adapted to different can formats.

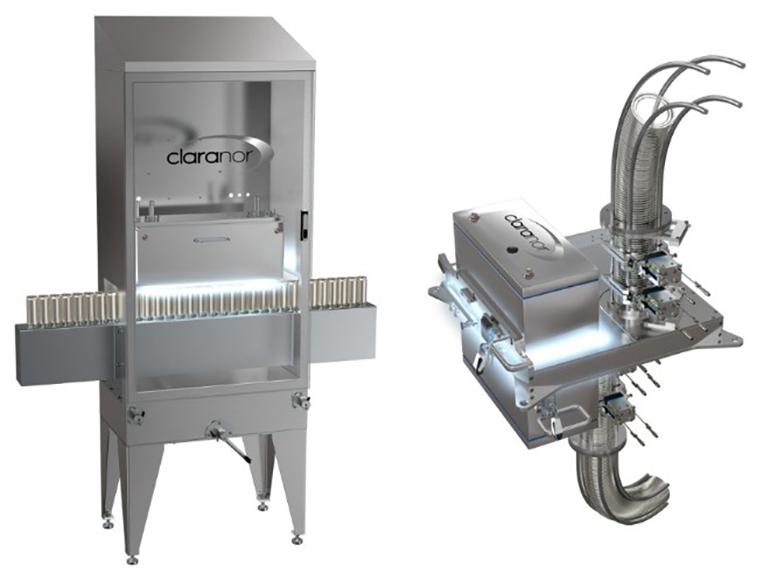

A new fully redesigned cap decontamination machines offer a full range in terms of speed, adapted to ultra-clean, ESL and high acid aseptic. Depending on your needs, Claranor offers inner or inner & outer decontamination of the cap. Instant and efficient chemical-free cup & lid decontamination by Pulsed Light, class IV VDMA.

Infant formula powder in METAL CAN benefit now from the efficiency of Pulsed Light decontamination as well as CAP AND SCOOP CAP. For BAG & BIG BAG, moving from medium to high care production area, we develop standard decontamination equipment customized according to production needs.