D.C.M.: for fifty years, a single partner for complete solutions

From food to transport and robotics: the company will be present at Ipack-Ima as a partner of choice for industrial packaging, whose success lies in customer satisfaction and providing responses to the demand for sustainable solutions.

Founded in 1974, D.C.M.’s core business is the distribution of paper folding machines for the pharmaceutical, paper processing and graphic arts sectors in general. However, its ability to evolve and its desire to bring innovation in-house have enabled the expansion of its portfolio to include new packaging solutions. In order to respond to different customer needs, D.C.M. now also offers dispensing, conveying, handling and robotic handling systems for a variety of product sectors.

In addition to the Guk brand, D.C.M. is also the exclusive distributor of Kraus, Autonox Robotics and BVM Brunner solutions in Italy, making the company the supplier of choice for machinery manufacturers. These solutions will be effectively showcased at Ipack-Ima.

Unrivalled expertise in paper folding with Guk

Over the years, D.C.M. has acquired unique expertise in supplying and installing Guk products, renowned worldwide for being practical, robust and reliable. The formats produced by Guk machines are extremely varied, with folding lines reaching speeds of up to 600 units/min and guaranteeing higher-quality finished products, thanks to the consistency of the results and the use of unique, patented solutions.

Standard versions can be equipped with accessories and add-ons to further extend their capabilities. These include, for example, the automatic vision and rejection system to eliminate the risk of components getting mixed up. Thanks to Guk technology, millions of brochures are produced every day in Italy. This performance has allowed the company to develop an original system that avoids impacting the productivity of machinery. The Mercurio solution not only monitors and collects data from the machine to plan maintenance work, but also allows machines to be interconnected according to Industry 4.0 criteria.

Ipack-Ima 2025 will see the presentation of one of Guk's most eagerly awaited innovations: the PP Cobo system, a state-of-the-art solution for the automation of folded leaflet collection. This system, equipped with a collaborative robotic arm positioned downstream of the folding line, is able to independently pick up the leaflets and place them neatly in the trays provided on both sides. By taking care of the repetitive collection operations, the Cobo PP allows operators to concentrate on the subsequent stages of packaging, thus improving the efficiency and continuity of the production process.

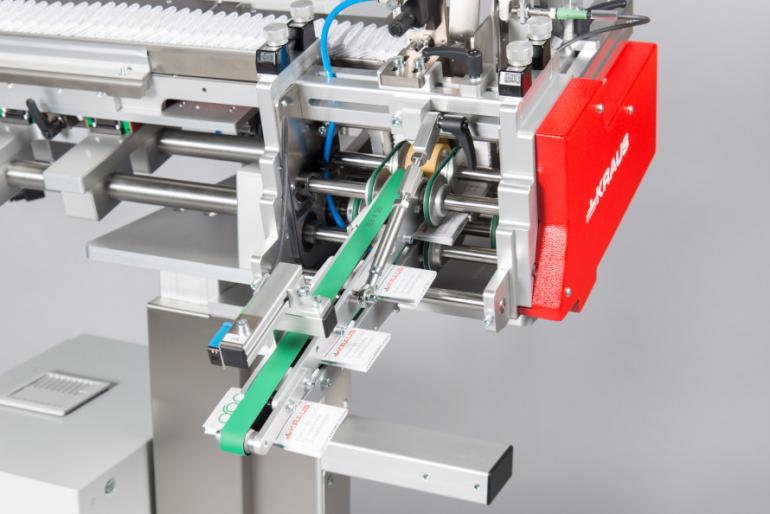

Dispensing, transporting and processing products with Kraus

Kraus feeders are designed to work at an industrial pace, and are ideal for dispensing products at high speeds in a variety of goods sectors. The growing attention paid to sustainability in recent years has led to the transformation of machines, adapting them to the demand for environmentally friendly, green packaging. The increasing use of recyclable materials in the production of disposable cutlery, cartons and trays has also led to changes in the technological solutions adopted for their individualisation and distribution, which are carried out completely automatically on the production lines.

D.C.M for the pharmaceutical market with Brava

This is a question that is also directly relevant to the pharmaceutical sector, of which D.C.M. has very thorough knowledge. And it is precisely the know-how acquired in pharma that led to the development of a novel solution, with the Brava product family, in response to the increasingly frequent demand to replace thermoformed plastic trays with an environmentally sustainable alternative. Consisting of 3 different machines, Brava provides a cardboard support with 2 to 6 rows of cusps that accommodate products such as syringes, bottles and vials during packaging.

Labeljack, for special processes

The Labeljack labelling system for special processes is characterised by its high cycle speed, Industry 4.0 readiness and ability to handle different label formats. Among the many processes developed for special lines, labelling systems play a prominent role, especially because of the high level of customisation offered. Labeljack's built-in control system is able to define settings such as language, interface and label format memory. Thanks to its unique locking mechanism and ease of use, simple handling, maximum precision and dynamics are guaranteed.

Industrial Robotics and Digital Twin

The evolution of information technology and electronics has enabled the development of new advanced industrial robots such as those under the Autonox Robotics brand, able to perform almost any type of packaging and handling task on products of different weights and sizes.

The entire range is controller independent and consists of duopods, 3- to 5-axis Delta robots, 3- to 6-axis anthropomorphic robots and SCARA robots, capable of working with fast cycles and meeting different payload and area requirements: from 0.5 to 350 kg and from 200 mm up to 2838 mm. The standard versions are complemented by the revamped Hygienic Design versions for working in primary packaging with IP69K protection, and by the revolutionary anthropomorphic robotic arms dedicated to CNC machining.

With regard to robotics, the demand for simulation of production processes has been growing in recent years, in particular for virtual testing of robots through the use of the 'digital twin'. In keeping with its hallmark culture of innovation and value creation, D.C.M. has integrated its offer with the possibility of simulating the customer's robotic application using virtual commissioning software. Added to this is the possibility to propose the right robotic sizing and testing the feasibility of a project, offering a major technological advantage that in most cases can replace the physical testing part of the machine.

Pre- and after-sales support with OPTIMAC

D.C.M. offers not only solutions and products, but also consulting and support, which the company has combined into a proprietary brand that encompasses all the support, consulting and training activities provided. With 'OPTIMAC', D.C.M. offers maximum efficiency and professionalism in supporting customers at all stages, from preliminary design to spare parts and maintenance.