Electronics revolutionises chocolate packaging

From mechanics to mechatronics with Schneider Electric. By integrating electronic axes and digital components, SACMI's Packaging & Chocolate systems achieve superior performance, greater sustainability and precise consumption control - all while improving product quality.

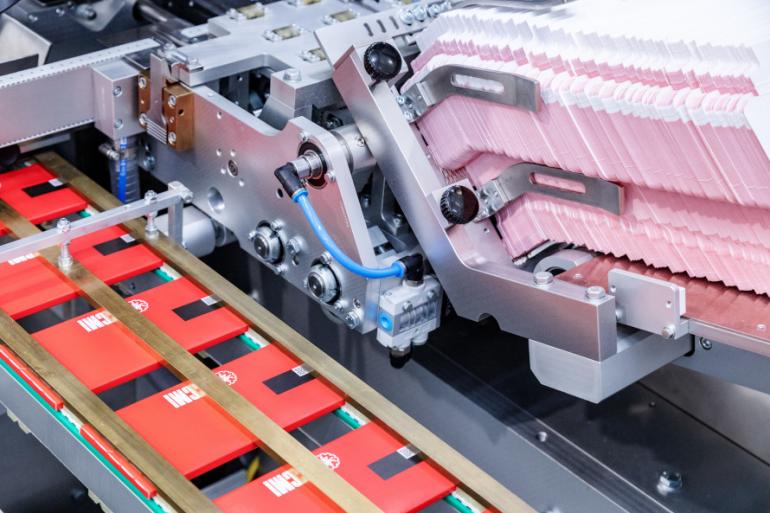

With the market launch of HTB - a new wrapping machine for chocolate tablets and bars in the traditional wrapping style - SACMI Packaging & Chocolate offers 25% higher productivity than its competitors, 40% lower energy consumption, significantly reduced machine downtime, and a drastic decrease in restarts after format changes, thanks to the elimination of mechanical cams and gears.

Versatility that supports customer growth

For the Packaging & Chocolate division of the SACMI Group – a global leader in advanced ceramic and packaging technologies with more than 70 production, distribution and service companies across 28 countries – the decision to enhance plant performance with the use of electronic axes alongside mechanical ones has marked a significant turning point, generating benefits that have exceeded expectations.

SACMI's chocolate production and packaging systems and lines are designed to cover the entire industrial process – from cocoa mass processing to primary packaging (both traditional and flow pack) and secondary packaging. Downstream of these stages, the company's customers are able to produce finished goods ready for distribution and sale. This comprehensive process includes all key stages of raw material transformation, such as refining, tempering and moulding, i.e. the actual creation of chocolate pralines or tablets.

“Responding to the evolving needs of our customers, we have completely rethought our machine design philosophy,” says Ernesto Gabrielli, Wrapping BU Director at SACMI Packaging & Chocolate. “This involved adopting a different approach and going well beyond a simple repositioning on the market.” “We moved away from mechanical technology and adopted a fully servo-driven architecture, providing an electronic axis for each functional axis of the machine. It is a true revolution and an ambitious project, brought to life through our collaboration with Schneider Electric, and one that has delivered exceptional results.”

“Our new machines offer a 25% increase in productivity compared to the performance of competing systems,” Gabrielli adds, “all while maintaining consistently high quality and reducing waste.”

These figures are further enhanced by the system's increased flexibility, especially when production schedules need to be adjusted. “Switching from one production format to another is now quick and easy, thanks to intuitive controls that replace complex mechanical adjustments. This minimises downtime and allows production to resume rapidly and efficiently.” What's more, reduced maintenance means greater ease of use. “A simplified user interface, based on preset recipes, makes the machines accessible even to less experienced operators.”

Sustainability and food safety

The optimisation of traditional technology through the introduction of electronics has eliminated the need for oils and greases, thus reducing the risk of product contamination – a critical concern in the food industry – while also lowering environmental impact.

“The evolution of our equipment has eliminated the risk of lubricant leakage,” Gabrielli emphasises. “This has now become a decisive factor for our customers, as the demand for oil-free lines is growing rapidly.” But the benefits of combining performance with sustainability don’t stop there. “Thanks to the electronic platform we have adopted, our systems can regenerate energy during the deceleration phase of the axes in their reciprocating motion,” Gabrielli continues. “This translates into significant energy savings for users of our systems.”

Preventive maintenance through digitisation

The advantages of using electronics extend well beyond this: the company is now able to know the “health status” of the machine in each of its individual axes with a frequency of one millisecond, which is impossible in mechanical solutions. “We can equip our lines with monitoring systems,” explains Gabrielli, “allowing us to detect and prevent potential issues such as interference or collisions during production. This approach helps us avoid major downtimes.”

A successful partnership

For the Packaging & Chocolate division, the partnership with Schneider Electric and the adoption of components from the PacDrive 3 range have enabled a true paradigm shift. The evolution from mechanical to mechatronic systems is a key part of SACMI Group’s broader transformation strategy, which is fully aligned with its commitment to research and development. The goal is to deliver increasingly efficient, flexible and sustainable solutions that respond to the demands of a constantly evolving market.