The industrial metaverse according to Siemens

Tangible digitalisation and innovation ready for the market at the “Xcelerator event”, organized in Milan on 29 March.

M. Costanza Candi

Smart buildings, collaborative robotics and machine learning, as well as underwater farming designed by a digital twin: these are the contexts of the three case histories that have provided a touch of concreteness to the already solid digitalisation path undertaken by Siemens, arriving at its full expression with the Xcelerator open digital platform, designed to facilitate interactions and promote innovation between customers, partners and developers.

Xcelerator is, in fact, an environment that includes a complete portfolio of hardware, software and digital services enabled for the IoT of Siemens and certified third parties, in addition to being an ecosystem of partners and evolving marketplace to facilitate interactions and transactions between all the parties involved. Floriano Masoero, Chairman and CEO of Siemens Italia and Head of Smart Infrastructure spoke about it to the press alongside Giuliano Busetto, Head of Digital Industries, explaining what the new open digital platform represents with respect to Siemens’ strategy, describing success stories and different aspects of the industrial metaverse.

From simulation to reality

Synapses, EPF and Nemo’s Garden are the three companies featuring in the event, which recounted how access to the basket of Siemens products and solutions, organised today in the Xcelerator platform, has been for them a fundamental stimulus for business innovation and development thanks to tools such as digital twin, AI, machine learning and simulation, as well as the support of a team of technicians and consultants on hand for the companies in every phase of project development.

While digitalisation is a daily concept for Siemens extended to suppliers and customers, the Xcelerator event has made it possible to experience first-hand a new frontier: the industrial metaverse. The participants in the event were able, in fact, to experience the results of Siemens’ strategy for the next few years, thanks to the Industrial Metaverse applications and the immersive environments created with the NVIDIA Omniverse™ platform, developed by the digital graphics giant for 3D design and collaboration. Immersive environments, the Industrial Metaverse with Siemens’ “physical” digital models and NVIDIA’s real time artificial intelligence have, in fact, permitted the management of a robotic cell in the factory, design and optimise a building consumption management system and learn how underwater agricultural cultivation works.

In the factory, in water, in smart buildings

The success stories refer to very different markets, united by a shared accelerating element: digitalisation. Synapses, in fact, recounted how the collaboration with Siemens made it possible to reinforce its technology that integrates Indoor Location systems and interaction with IoT and WoT (Web of Things).

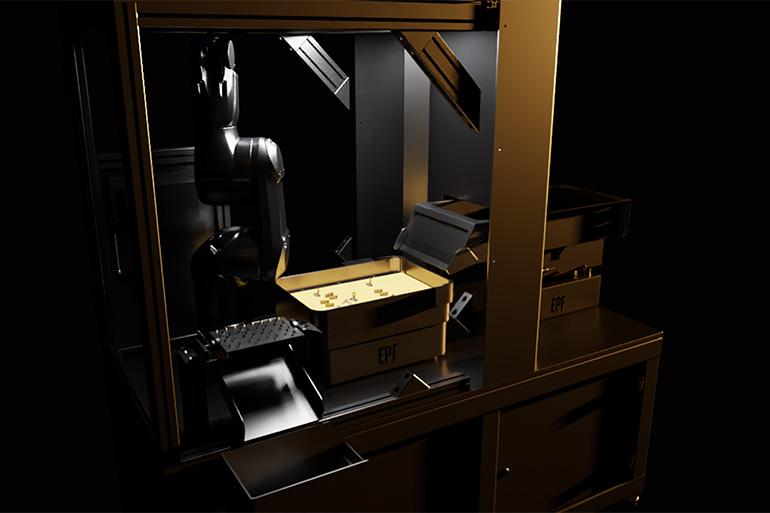

Supata AI, EPF’s robotics solution, demonstrated how the industrial metaverse can be applied to a robotised island able to manipulate a variety of components and to automatically recognise the pieces inserted in the database thanks to an AI-guided vision system, making it possible, in fact, to introduce new pieces into production without having to reprogramme the machine.

Nemo’s Garden, the sustainable underwater greenhouse founded in 2012 in Liguria, is able to exploit the marine environment for cultivation. Thanks to the development of a complete digital twin of the biosphere, the team is able to test every new cultivation in the virtual environment, without having to develop a physical version, with obvious advantages for the project’s start-up company.

Finally, Deop X demonstrated the optimisation of distributed energy resources and the relative reduction in energy costs and CO2 emissions thanks to the management and optimization of resources.