Vision: a smart melter at the end of the line

Robatech supplies IMACH Innovative Packaging Solutions with a new standard component for the application of hot-melt adhesive - the Vision melter - adopted on the end-of-line packaging machine of Caffè IZZO. The reasons for the choice? Quick maintenance, easy integration, simplicity of use.

Previewed in March 2021 during the Robatech Virtual Event (an event that, due to its workmanship and content, received well-deserved and sincere appreciation, Editor’s note), the Vision smart melter and the new Performa electrically heated hose aroused the immediate interest of IMACH, a specialist in customized end-of-line packaging systems..

On the strength of a long-established partnership with Robatech, IMACH was able to offer the best in terms of technology and performance to one of its customers in the food and beverage segment, Caffè IZZO.

Productivity choices

Since 1975, the roasting company and manufacturer of coffee blends and machines has been supplying hotels, bars and restaurants, moving in 2010 to offer products to private individuals as well. Since 2016, with the production of coffee in pods and capsules, the packaging process has become increasingly complex and time-consuming, making manual operations obsolete. Hence, the need expressed by Caffè IZZO to optimize the closure of the packages with a clean and safe bonding, finding in the Vision melter and Smart Terminal the suitable - and adaptable - answer to the production line installed in the company.

The technological (and sustainable) answer

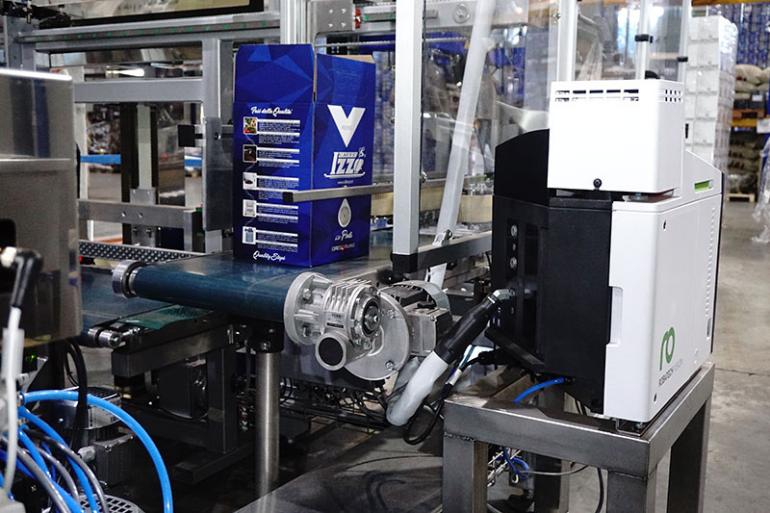

The system supplied by IMACH mounts shipping boxes with self-locking bottom and fills up to 750 coffee capsules per minute, with top-loading procedure in packs of 50, 100 or 150 capsules.

The end of the line sees an AX Diamond Robatech heated head operating on two beads of hot-melt adhesive, placed on the two short flaps of the lid. In the next step, the long flaps of the lid are closed and briefly pressed. All in all, the system glues about 15 packs per minute, which are then sent to retail channels.

In fact, Vision opens up a new dimension in the melter market, thanks to the function that regulates the heating temperature quickly and precisely, ensuring a stable feed pressure.

The fully insulated Performa electrically heated hose is connected to the Vision melter and applicator head via the PrimeConnect quick coupler. In this way, the temperature is kept constant as is the viscosity of the adhesive, for uniform and reliable bonding.

And there is also sustainability, among the many contents that characterize Robatech’s offer. The new melter requires 20% less energy than the previous model.