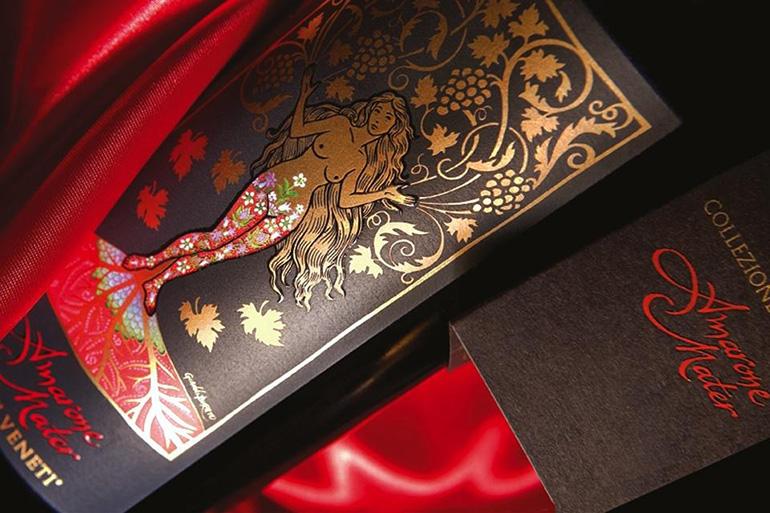

Precious and limitless labels

State-of-the-art technology allows for the raising of label printing to an art. The siblings Anna and Sebastiano Lonardi, part of the second generation at the helm of Grafical (based in Marano di Valpolicella, VR), the company specialised in the production of adhesive labels for the wine&spirits sector (but not only), are convinced.

Meeting every type of request, reducing printing times and, in general, offering a top-level service in order to free up the creativity of its customers and produce quality: these are the goals achieved with the recent investments made by Grafical in upgrading its already cutting-edge machinery. Below we describe the main innovations.

For an improved management of the media

Producing labels for the “wine world”, Grafical has always preferred sheet offset machines because they’re very versatile in the management of the media. The Heidelberg Speedmaster CD74 has, therefore, been “retired”, being replaced with the sheet offset Heidelberg Speedmaster XL: the same machine, the same brand, the same series, the same modular configuration, but an updated model.

And while the CD74 has guaranteed many millions of labels printed with exceptional performance levels, the new arrival promises even more, thanks to the technological colour control apparatus with spectrophotometer in the line and a number of completely new functionalities.

As well as even more impressive printing speed and capacity, great attention has also been paid the consumption of materials: the Speedmaster XL is equipped with an innovative system that allows for the recovery of the foil. While, up until now consumption has been determined by the height of the media, the new technology of the coldfoil model is able to manage movements, limiting use of material only to the finished area.

It's time to “flex” labels

Appreciated in all situations in which it’s necessary to produce high volumes with a low unit cost, flexography is recognised for its speed (the secret is the flexible and soft relief printing matrix, which transfers ink directly to the support to be printed), but certainly not for the ability to produce high-quality printing, also considering the fact of not being able to add finishes.

Today, however, with Nipeter’s FA-Line flexo printing machine, Grafical is able to offer extraordinary things, overcoming the limits inherent in the technology. Thanks to a configuration designed ad hoc for the company, the FA-line integrates into numerous processes, avoiding, for example, the need to transfer a partially finished print to other systems in order to carry out the finishes.

Besides the five flexo units, the FA-Line used by Grafical also has a hotfoil line relief and bas-relief, a coldfoil line, high thickness digital painting unit with UV Led drying and a die cutting module for shaping.

And to finish…

It should be noted that Grafical is one of the few Italian printers to use the Kurz Trustseal Spatial FX technology, a unique technique for creating three-dimensional effects through optical illusion. Additional services offered by the company include high-quality overprinting of labels and the production of multilayer labels obtained by laminating different materials.

Since 2019, Grafical has no longer limited its activities to the printing of adhesive labels. In that year, in fact, it acquired 50% of a paper converting company (a trusted contractor), and now the company produces uncoated laminated boxes, carries out die-cutting and gluing and other processes, with the objective of combining label and box to be offered to high-end sectors, such as cosmetics.