High-end: smart, sustainable and ennobled printing

SEEN AT PACKAGING PREMIÈRE 2022. How is the current economic climate - a shortage of raw materials and rising energy prices - affecting the business of converting companies? What ennoblements are most in demand in the market? What importance is being placed on sustainability? We posed these and other questions to some of the companies that chose the Italian luxury packaging fair to unveil their new products and market visions.

Cristina Rossi

The fourth edition of Packaging Première, which was held May 24-26 at Fieramilanocity, in conjunction with the first Italian edition of PCD Milan, was attended by 5,900 visitors, who were able to learn about the product innovations of more than 270 exhibitors from 24 countries.

«This edition represented in our opinion the real restart», said Pier Paolo Ponchia, founder and director of Packaging Première. «It was once again possible to see the latest product innovations up close, find new business insights and share ideas and opinions in an industry that is moving in step with change, sustainability and innovation. We are satisfied with the result achieved and we give everyone an appointment from May 16 to 18, 2023 for the next edition».

More than two years after the onset of the pandemic - which we have not yet completely left behind - and several months after the start of the conflict in Ukraine, Packaging Première was thus trying to gradually return to a new normal, which meant slowly moving out of a work dimension of smartworking and webinars, returning to travel and attending conferences and trade shows in presence. The three-day fair clearly manifested the desire to come together again, and companies said they were ready to revive their businesses, despite the decidedly challenging economic conditions.

Cristina Rossi

Freelance journalist and communication expert in the field of graphic arts technologies.

Smart printing and the resurgence of print media

The first company we met is Arti Grafiche Nidasio, which is celebrating 100 years of history this year and is making its printing expertise available to all major market sectors: fashion, luxury, jewelry, furniture, pharmaceuticals, consumer goods, direct sales and more. Both offset and digital printing are handled within the company, often complementary in the sense that offset prints are customized digitally.

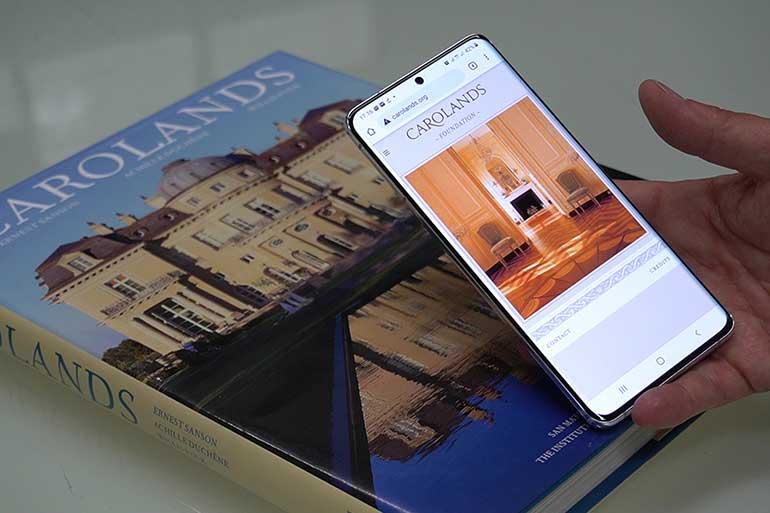

But the real innovation of this company is its digital “rib,” namely Arti Grafiche Nidasio Digital, founded a year ago by Giorgio Nidasio, sole director of the innovative start-up, together with two partners, Riccardo Tonon and Davide Danise. «The mission of the fledgling company is to publicize the Intelligent Print - explains engineer Nidasio - which at this fair is represented by a ‘talking’ box, selected for the Avant Garde exhibition».

This is a contactless solution that allows smartphones to interact with printed matter, simply by touching the paper.

As of today, no more apps or QRcodes are needed: the platform uses the already well-known NFC (Near Field Communication) technology to convey multimedia content, process statistics, and pave the way for new, unprecedented applications...... much more than just a WOW effect.

The secret lies in the technique of using chips-a solution protected by an international patent-that can be inserted into any type of printed matter.

«We have our own computer platform developed by my associates - Nidasio points out - which allows us to insert multimedia content into a printout that can be updated at any time, without the need to reprint and redistribute it. In this way, the printout becomes interactive, creating greater customer engagement through audio and video content or with Augmented Reality.

If, for example, I have already distributed printed materials, they will still be relevant the following month because they will hook a new video. If I have made a catalog, I can be notified when an individual customer uses it and know what they are interested in before I even call them.

It’s a great idea for large retailers: by touching a display or a postcard with your smartphone, each package, when framed, will tell about its contents and will do so even before the purchase... hence the message presented to Avant Garde of the “box that talks to you.”

It’s as if we have revived printed paper...and now the Intelligent Print is our flagship to attract new customers and implement projects that use technology and data to constantly measure and improve business results».

Specialists of cold lamination on natural paper

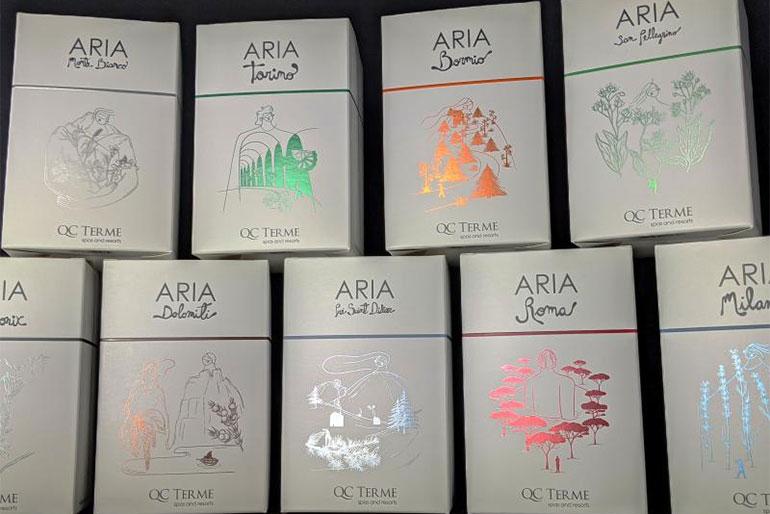

On the international stage of Packaging Première, which has now become a meeting point for international designers and brands, Grafiche Erredue presented itself with the ambitious claim “Let’s make our ideas fly.” Welcoming us were father and son, Angelo and Paolo Radice, respectively owner and sales manager of the company, which will celebrate its 50th anniversary next year.

«Our mission - Erredue’s founder explains - has always been the pursuit of beauty, pursued through experimentation with the most innovative finishing techniques, such as drip off, screen printing glitter, glossy UV varnishing, dry embossing and thermo-impression, pearl varnish, thick UV varnishing, flocking, metallic colors, die-cutting, pop-up packaging and many others».

But what has made the difference since 2012 has been cold foil lamination, a process that is a source of pride for the company, which is equipped with two 70x100-format Roland sheetfed offset presses, one 5 and the other 6 colors. On the latter two years ago, UV LED was added to the final output.

Cold foil, or cold foil, is a lamination technique that involves transferring metallized films directly onto the substrate using a specific plate and glue instead of plates, heat and pressure. The effect is precious, creative and noble and has an affordable cost.

«Sometimes we use foil with UV technology and not LED UV to have more guarantees - Angelo Radice points out. «We are currently testing a new glue from Kurz/Luxoro. Since last December we have consumed as many as 40 reels of 10,000 meters of foil».

Usually cold foiling is used on coated papers, but Grafiche Erredue was among the first to use it on natural papers as well.

«Some clients - Angelo Radice continues - came exclusively because they were aware of this application on natural papers, and I am referring in particular to operators in the fashion sector. We were born with paper, printing brochures and catalogs for important clients in the automotive sector, such as Citroën. We entered the packaging market initially by doing contract work, while now we operate directly».

As his son Paolo adds «Since 2012, it was cold foil that made our business migrate to paper converting, which currently accounts for 70 percent of sales, amounting to 4 million annually with 20 employees. We have been running trials on natural papers for over a year now. We recently did a nice job with a company in Florence, which produces gift papers embellished with gold powder and was looking for a more sustainable procedure: hence our proposal for a cold foil with the same gold shade on natural paper, which met with the full approval of the manufacturer. Now we are developing an important packaging project for a brand in the cosmetics sector, which wants to use Fedrigoni’s Old Mill natural paper».

«The shortage of raw materials has not penalized us - Angelo Radice concludes - because we have a stocked warehouse, which guarantees us a few months’ autonomy. And now that the increase in paper prices seems to be easing, we can wait to place new orders».

A path of eco-sustainability

Tonutti Tecniche Grafiche, 77 years in business behind it and 200 million labels made per month at its plant in Fagagna, Friuli-Venezia Giulia. At Packaging Première it presented some self-promotion projects carried out together with its media suppliers and in-house designers.

The company, which specializes in the production of self-adhesive labels, has been on a path of sustainability since last year, both at the process level, with a significant reduction in waste, and at the product level.

Sealing this path was the publication last December of the first Social Report.

«Choosing to go down a sustainable path - explains Barbara Pagnutti, marketing manager - translates not only into changing our business organization in a way that respects the environment and people, but also into giving customers the opportunity to choose a green product».

This awareness gave rise to the Tonutti Green brand, a dragonfly whose wings draw the ribbing of leaves, a symbol of nature. This is also the origin of the preference for natural papers as an alternative to pearl and metallic papers, which have a significantly higher ecological impact.

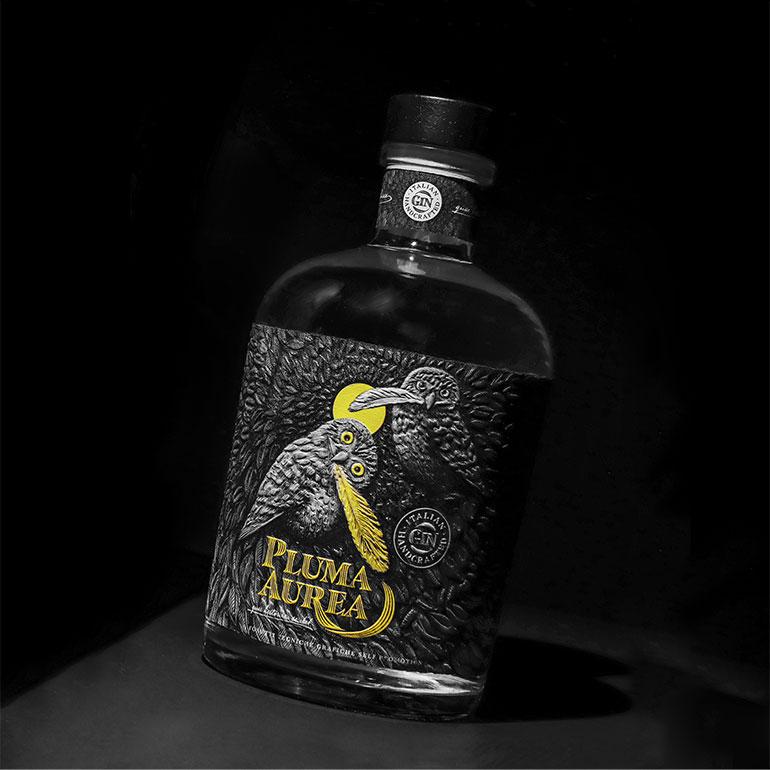

The Pluma Aurea, a totally sustainable project presented at the fair together with Avery Dennison, best expresses the company’s green spirit.

«The display on which the bottle rests - says Barbara Pagnutti - was made from the cores of our coils. The label is printed on ennobled cotton paper with incredible relief. The bottle holder box is a beautiful example of recycling: we start from the core of a reel, so a poor product destined for waste, which becomes first and foremost a bottle holder, but earns eternity by transforming itself into a furnishing complement. The clock on the bottle rack marks the passage of time in the alternation of day/night, while some owls dip a feather into the moon or sun and go on to write the history of Tonutti».

Linked to innovation and the new Tonutti Innovation Act brand is, on the other hand, the second project created in collaboration with Fedrigoni and Luxoro for foils.

It is a label celebrating 100 years since the discovery of Tut Ankh Amun’s tomb. The acronym KV62 refers to the 62nd tomb discovered in the King Valley (KV), which was precisely that of the celebrated pharaoh. The bottle with an outer wrapper - removed on the second day of the fair - is reminiscent of the decorations on one of the sarcophagi and features an evocative seal.

«It is a project that sums up our savoir faire, showing all the refinements we are able to offer: special die-cuts, perforations, machine coupling of different materials, embossing, foils and thickened varnishes. These are machine-replicable prototype».

Pagnutti concludes with a mention of the shortage of raw materials, which undoubtedly has also challenged labelmakers.

«When the problem arose, which we dealt with excellently thanks to our purchasing department’s habit of planning supplies over the long term, we helped the customer find an alternative in case the paper of his choice was not available. Supply times have naturally lengthened, so we encourage our customers to make long-term planning. But right now, even the ‘hardest’ customers are willing to make some compromises in terms of raw material as long as the label is printed».

Customization at the heart of production

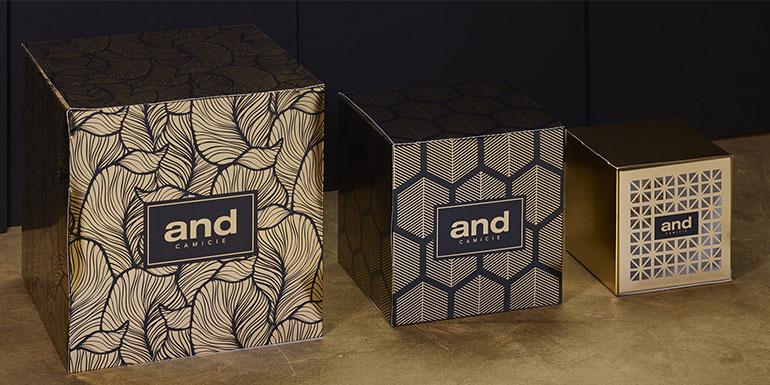

At Packaging Première, Grafica Valdarno, a long-standing company specializing in premium printed matter and high-end packaging, was not exhibiting the products it usually makes for clients, but rather packaging and ennobled printed matter created specifically for the fair.

«This strategy was dictated by the fact that we do not have standard products, rather we create them ad hoc - Emilio Bonavia, the company’s marketing manager, confided to us. «However, we showcased all the potential of ennobling and how we can decline them to make a custom product. We were inspired by the famous Dostoevskian maxim ‘Beauty will save the world’ to create a project with very high technical content that could combine creativity with feasibility. Beauty is not only in art or nature, but also in craftsmanship that knows how to sublimate beauty through the contribution of the whole team».

And with lively participation, Bonavia described the work to us in detail, thanking the Carlo Gasperini company for their valuable collaboration in the making of all the plates. Here are some sample plates.

In the first plate, depicting the circle of nature, the quintessence of timeless elegance, the three-dimensional multi-level dry relief shows a contrast that is emphasized by a pearl offset varnish.

The second panel, dedicated to nature, features a maxim of Epicurus: “One should not do violence to nature but persuade it.” Here stands out an image of the moon, recreated directly on paper, where sphericity plays in perfect synthesis with the techniques of emboss, deboss, light and shadow to reproduce its craters exactly as we see them in the sky on full moon nights.

In another panel, a female face embodies spring, heralded by Pablo Neruda’s phrase (“I would like to do with you what spring does with the cherry trees”), where the word “spring,” hot stamped with satin-finish, connects to the metal and 3D relief flowers gracefully placed on matte gold hair.

Audrey Hepburn (“Elegance is the only beauty that never fades”) inspired the company in its search for the sensory detail of its scarf where thermography surprises with striking color effects as well as engaging the tactile aspect.

Another panel, dedicated to Rudolf Nureyev (“He who flies high is always alone”) depicts a ballerina whose stroke was created with an evocative effect of transparency (hot stamping on Moondream light paper) that extends to a silver moon which wants to celebrate, with its light (and hot stamping with micro-etching with pearl foil) the poetess Sappho.

“First I dream my paintings, then I paint my dreams,” said Vincent Van Gogh, to whom the prelude board is related, where the word “dream” (through micro-engraved hot stamping with very fine graphisms) echoes the style of brushstrokes we will find in the Notte Stellata, the next board, made on black pulp paper as the basis for the night landscape, printed with 5 UV colors and thermography that reproduces the short modeling and textural brushstrokes creating an overall harmony between colors, shapes and figures.

Finally, in the panel focusing on music (“Music teaches us the most important thing there is: listening,” Ezio Bosso) the iridescence of the micro-engraved notes, as if they were moving on the staff, creates a dynamic effect in the word music. This is followed by Kandinsky and the visual language of shapes, colors and lines made with masks of white, UV offset chromatics and thermography.