Designing automatic machines

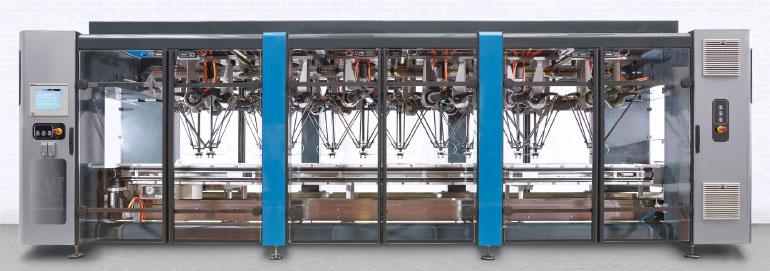

Bosch Rexroth supports manufacturers throughout the creation and production of packaging machines, leveraging virtual simulation, data processing and artificial intelligence.

Packaging companies need to quickly develop machines or lines suitable for packaging a specific product, and it is often not easy to find a compromise between the need for high customization and the increasingly tight deadlines of the market.

Bosch Rexroth has succeeded in defining a process to work alongside machine manufacturers so that they can respond adequately in the time and manner required by customers.

The stages of the process

First, the design is simulated virtually so that changes can be made and evaluated to see if they meet the design specifications.

In the second phase, the machine is built by adding the components already identified during the simulation phase.

Finally, once the machine is created, in the commissioning phase the performance is monitored and optimized through data analysis, also setting up predictive maintenance logics.

“Virtualize” to save money

Today the most important phase is the virtualization of the machine. In this context, Bosch Rexroth is able to provide the manufacturer with the virtualization of all components, thus allowing to completely simulate the behavior of the machine, saving time and development costs. Thanks to the ctrlX AUTOMATION platform, it is possible not only to evaluate the physical behavior of components, but also to fully test the machine software in a virtual world, reducing commissioning time by 80%.

Data flow and artificial intelligence

In the world of packaging, the use of connected technologies is fundamental. With this in mind, all products in the ctrlX AUTOMATION platform have been developed to generate and send data. The use of ctrlX IoT enables the collection of data from PLCs, cameras or other devices and, from an edge computing perspective, transform it into information. This information can then be stored on local databases or sent to cloud-based services to leverage, for example, predictive maintenance, business intelligence or OEE optimization logic.

The latest frontier is artificial intelligence: AI algorithms can be installed directly within the machine control and go on to independently optimize production processes or anticipate any problems during the use of the machine itself.