Vials and bottles labelling: new standards of flexibility for pharma

Designed by Etipack, Pharma Flexi is the innovative ultra-high-speed pharmaceutical labelling system for all products cylindrical format, even unstable ones. Showcased at interpack.

The range of industrial labellers of the Etipack Pharma line dedicated to the pharmaceutical industry is now enhanced with the new Pharma Flexi, an automatic labelling system conceived for labelling, in a single solution and at very high speed, a variety of pharmaceutical products of cylindrical format.

The system in details

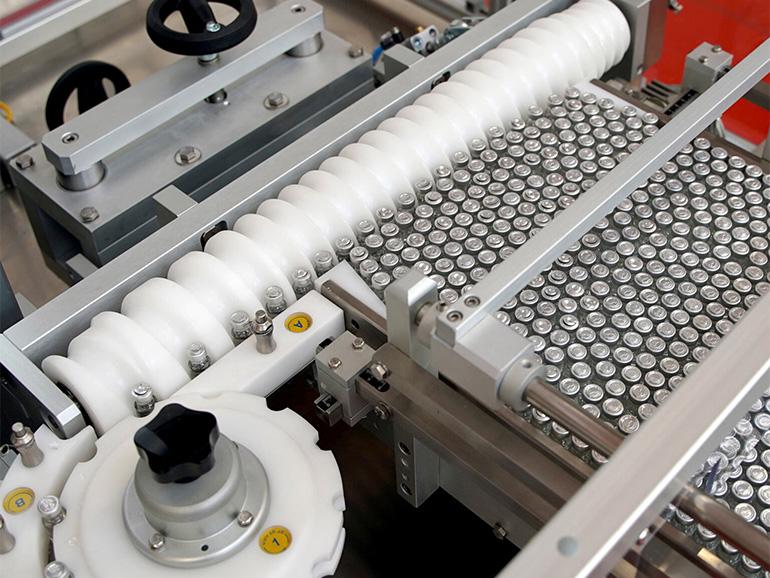

Designed to supply the market with a truly innovative product, Pharma Flexi is a rotary system consisting of an infeed belt for loading products, an auger for spacing and a transport and a conveying and phasing system to correctly contain the product when labelling.

The power of the new system lies in the perfect combination of labelling speed, easy format change and integration possibilities that clearly make it competitive in the panorama of systems for the industrial labelling of pharmaceutical products.

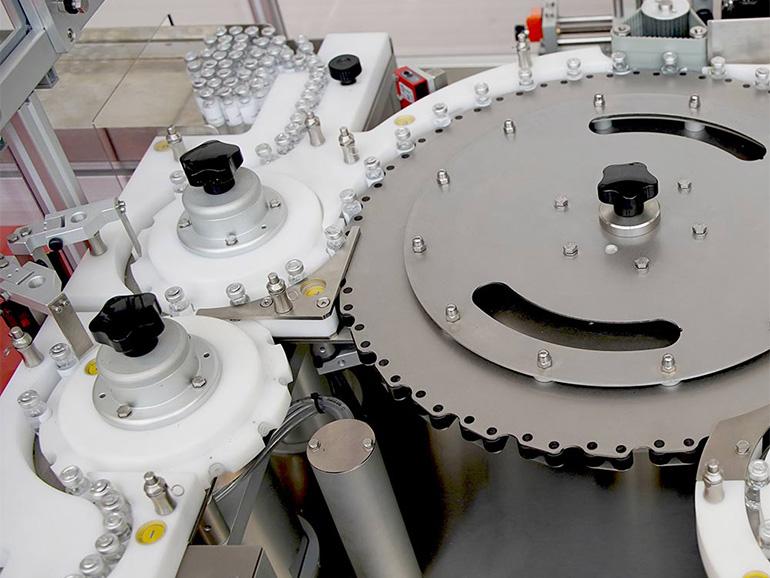

Pharma Flexi can reach speeds of up to 400 pcs/min depending on the format and specifications of the customer's line, and is designed to facilitate format changes, allowing for greater versatility in processing products with similar characteristics, enabling compatible machine configurations. As in all Etipack systems, the Pharma Flexi enables format changes to be carried out quickly and easily, without the need for any tools, by replacing the auger, the double infeed starwheels, the main operating wheel, the product rejection double stars, and the guides.

Flexibility both in-line and off-line

Another strong feature of the system is therefore the possibility of working either off-line or integrated in the production line, thanks to the presence of the screw conveyor which, by harmonising product movement, holds and transports the products towards the carousel, thus allowing very high labelling speeds. The rotary system also offers the advantage of being less sensitive to the height of the product, which, even if unstable gets stabilised.

When used in standalone mode instead, Pharma Flexi is equipped with a low-grip conveyor belt for loading the products in order to allow manual unloading and the corresponding manual tray feeding system of compliant and non-compliant products.

Intuitive management

Thanks to state-of-the-art electronics, remote controls and ergonomics, Pharma Flexi also offers high autonomy and flexibility when it comes to the management and control of inspection and maintenance functions as well as operations.

The control panel, equipped with pivoting arm, is designed to ensure maximum agility. Equipped with advanced electronics with PLC Siemens S7 for constant control of peripherals according the industry requirements, the panel allows to consult the wiring diagrams and the instruction manual, as well as to better manage maintenance processes. Designed according to GMP guidelines, it also allows the management of FailSafe functions, production batch and the collection of CFR21/ Events/Alarms and production data.

Labelling at the top level

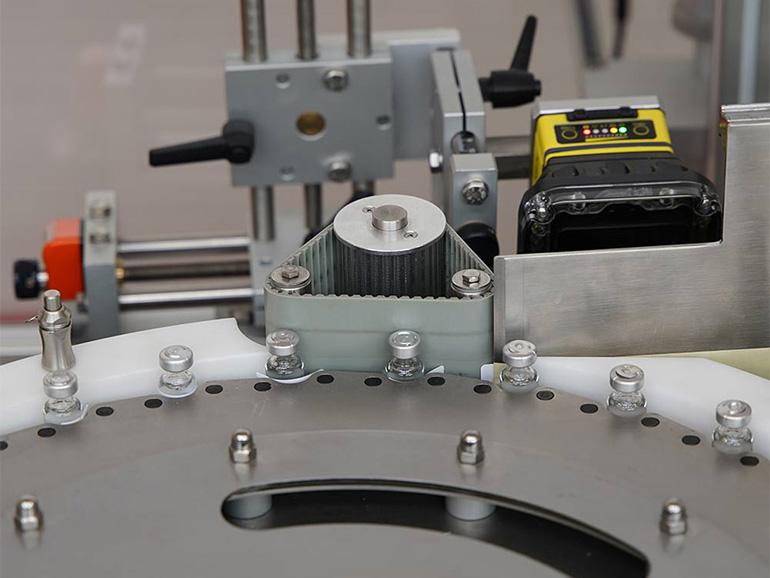

Thanks to the precision standards achieved, control in application and reject management is at its peak. Pharma Flexi is equipped with a special Kanigen-coated labeller, designed for high production speeds and specifically for the pharmaceutical industry. Placed outside the guards, it is easily accessible, simplifying management, inspection and maintenance operations.

Equipped with stepper motor with magnetic encoder, it achieves a distribution speed of up to 60 m/min, allowing to process labels up to 100 mm and can load reels up to 380 mm in diameter. The ergonomic touch screen display allows you to configure over 50 operating parameters, as well as saving customized configurations. The same parameters can be remote-controlled on the labelling system panel. The special retractable blade placed at the labelling area, facilitates the precise and smooth application of the label onto the product . The versatility of the system also emerges in relation to the possibilities of printing and control of variable data: the Pharma Flexi labeller features a station for the control of successful labelling with a UV barrier. It is also configured to integrate a printing unit for overprinting variable data and vision system for the control of barcode and/or OCR/V overprinting.

Finally, it is worth emphasizing another plus of Pharma Flexi, namely the advanced reject management. The system features two unloading stations for the products, which are conditioned thanks to the presence of a double star outlet, with suction system and fail-safe function, conveying them either towards the reject station, or towards the compliant products station, thus allowing correct sorting. The products are collected statically by dedicated trays with presence and maximum load controls.

Etipack

1978 Etipack designs, manufactures, and sells labeling and coding systems with self-adhesive labels, friction feeders, and pick and place for product handling and distribution. A leading company in Italy and among the largest in Europe, Etipack is today an international group consisting of subsidiaries and affiliates. Since June 2019 Etipack is part of the Possehl Identification Solutions division, owned by Possehl group. This organization, together with a widespread network of sales, distribution, and technical assistance in over 30 countries ensures a constant presence, accompanying our customers with their projects, from the very beginning to the end, and afterwards.