The advantage of expanded films: reduced density and weight

The Nextfilm™ range of films, launched in 2020 and constantly being updated, stems from Ticinoplast’s commitment to developing sustainable packaging solutions in line with the principles of the circular economy. Among the recently developed products are reduced weight expanded films in recyclable PE, suitable for food packaging.

One of the strategies implemented by Ticinoplast with a view to improving the sustainability of packaging consists in developing innovative solutions to reduce the weight of plastic films, thus obtaining a twofold advantage: in addition to “lightening” the environmental impact of the packaging itself, it makes the production process more competitive by using a smaller quantity of raw material.

It is essential, however, that the reduction in weight, obtained thanks to a lower film density, does not compromise the mechanical and sealing characteristics.

In strict compliance with these requirements, Ticinoplast has developed a range of expanded films with a reduced density (down to -0.78 g/cm3) that results in a weight reduction of about 15%.

Made of polyethylene and available in both HDPE and LDPE, white or transparent, they guarantee performance suitable for food packaging.

An innovative process

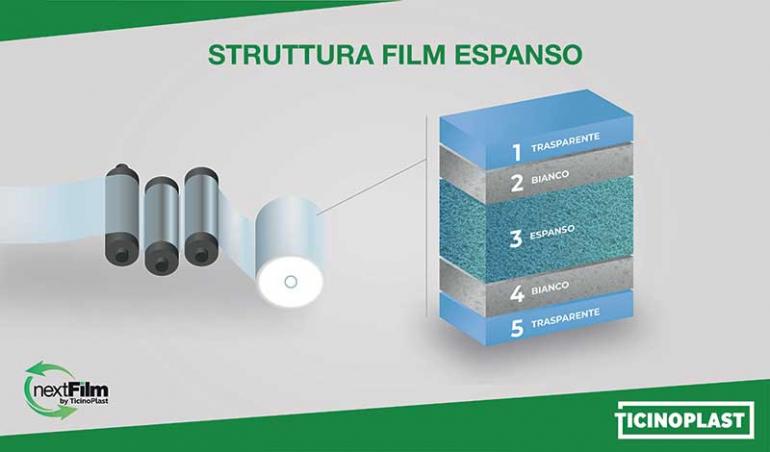

Ticinoplast expanded films are produced on a 5-layer blown film line. The technology adopted allows to expand only the central layer through the creation of micro bubbles generated in the inner layer thanks to the injection of gas during extrusion; in this way, during the injection phase, an easier filling and a physical expansion of the resin is obtained.

The result is a kind of foam with performances similar to those of a normal plastic film. The central layer remains expanded while the adjacent layers work as a barrier, ensuring the mechanical and sealing properties, and all the technical characteristics that allow the correct conservation of food over its shelf life, which are essential for flexible food packaging.

A range “in progress”

In addition to the traditional lamination foams, Ticinoplast is currently developing flexible films suitable for thermoforming, composed of a polyethylene foam laminated to a PE (with or without barrier, depending on the application), in order to offer the market a flexible “bottom” entirely made of PE.

Finally, we would like to mention the recent achievement by Ticinoplast of the ISCC PLUS certificate, which allows the production of expanded films also with resins coming from chemical recycling.