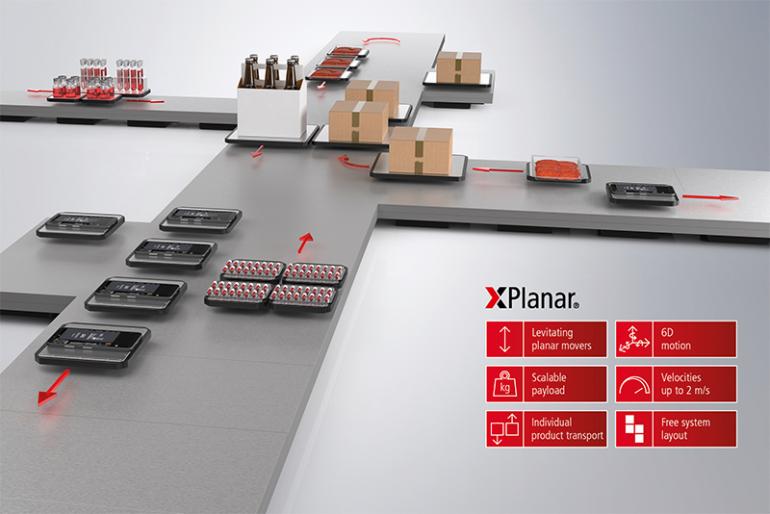

XPlanar: levitating, contactless, intelligent

Planar is highly flexible in adapting to a wide variety of transport processes in the most diverse fields of application, right up to the pharmaceutical and food industries.

The planar motor system XPlanar combines the advantages of conventional transport technologies with magnetic levitation. The levitating product transport enables a wide range of new options for handling products within a machine and also between several machines.

Similar to automated guided vehicle systems, Beckhoff’s XPlanar offers the user the benefits from the freedom of movement of the object carriers: individual goods can be transported to any location via any route. XPlanar combines this flexibility with the dynamics of conventional linear motors and offers added value through cycle-time-optimized linking of individual production steps. XPlanar significantly simplifies individual production steps because the degrees of freedom and accuracy familiar from robotics can be used for 6D product handling. The concept of product positioning during processing is applied to the transport system. The floating effect replaces all mechanical guide components and drastically reduces cleaning and maintenance costs.

XPlanar: maximum positioning flexibility with 6 degrees of freedom; movements in the x, y, z planes and 360° rotation.

Minimal cleaning and maintenance effort

No mechanical components are used to connect the tiles and the movers. In contrast to conventional transport systems, no guide rails, rollers or lubrication systems are required. The time required for regular maintenance intervals is reduced to a fraction, which significantly increases system availability. The absence of mechanical components simplifies cleaning of the system when used in heavily contaminated environments. All tile and mover surfaces are smooth and easy to reach.

Contamination of the production line – for example as a result of spilled liquids – can easily be identified on the flat surfaces, and spreading by other movers is avoided thanks to the floating effect. For use in particularly demanding environments, the XPlanar tiles can be covered with stainless steel, glass or plastic to protect them from aggressive cleaning processes. The floating properties of the movers are not affected.

XPlanar makes it possible to rethink modern production processes. Highly dynamic, sequential processes are the means of choice in many applications, particularly for quantity-oriented production. The optimization of processing and transport times can reach physical limits. XPlanar makes it possible to overcome these limits