Producing stick deodorants

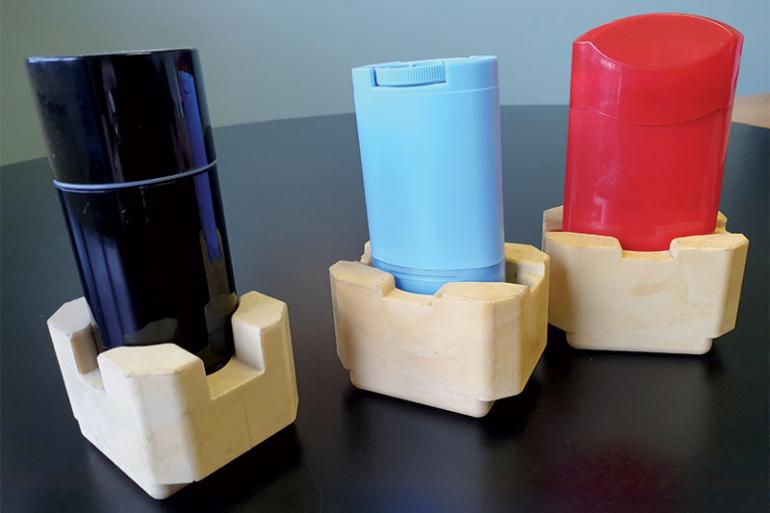

Historical presence at Cosmopack (this year in Hall 19, stand D2PK), Tecnicoll has been designing and manufacturing automatic and manual machines for the cosmetics industry since 1974, and is a leader in the production of packaging lines for hot-cast products, such as different types of make-up and stick deodorants.

In particular, for the latter product category, it has developed specific solutions for alcohol-based and antiperspirant formulations.

Tecnicoll lines consist of the assembly of different equipment, each of which performs a specific function: product preparation and mixing, filling and cooling, stick handling by means of conveyor belts.

Preparation takes place in one or more melters, built in AISI 316L stainless steel and mirror polished, equipped with a stirring system, a watertight lid, a condenser for the recovery of volatile compounds and prepared for the inputs of liquid raw materials and solid. The fuser tank is heated by a circulating fluid in the double jacket.

Filling of the sticks is by means of a AISI 316L stainless steel dispenser with one or more outlets with gear pumps and a constant level maintenance system (patented by Tecnicoll), which guarantees the precision of dosage.

The experience gained by collaborating with the various customers has allowed the company to perfect its construction technology, selecting, at the same time, the most appropriate materials to ensure optimal operation, even with the most complex formulations, such as those containing corrosive components

The research of materials, constantly updated, evolves hand in hand with the new formulations introduced on the market.

Cooling takes place in a tunnel with a refrigeration system sized according to production needs, and made with air circulation paths suitable for uniformly cooling the product, without altering the surface or the internal body.

The packaging lines for deodorants are also suitable for other types of stick products such as scrubs and shaving soaps. In this regard, a special calculation program has been studied which takes into account the average particle size of the dispersed solids, calculating the tolerances between the gears and the various components of the pump so as not to create abrasions on dosing head elements.