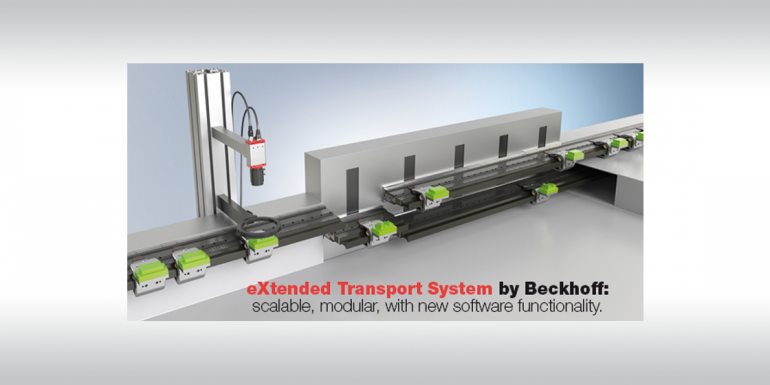

New features of the XTS software

Thanks to the excellent scalability in terms of computing power, functionality and costs, Beckhoff solutions are ideal for controlling the entire process from individual machines to complete packaging lines.

| Flexible entry and exit of the product with XTS Track Management allows individual items to be inspected and reworked without interrupting the production flow. |

Il sistema PC-based di Beckhoff è la soluzione universale di automazione che permette di incorporare in un solo PC sia HW che SW, nonché tutte le funzionalità di automazione di impianto: interfaccia uomo-macchina, PLC, movimento degli assi, comunicazione, safety, robotica, condition e power monitoring, visione, tecnologia di misurazione, controllo numerico, IoT e Analytics. Dispone dei connettori naturali per la comunicazione verso sistemi gestionali ERP e MES, usando protocolli di comunicazione aperti e standardizzati.

Beckhoff offre un ampio ventaglio di prodotti: dai terminali I/O, ai PC industriali e al SW di automazione, passando per motori e azionamenti elettrici, controllori e gateway IoT, analytics, sistemi di trasporto lineare, prodotti e soluzioni che trovano applicazione in tutti i mercati rispondendo, in modo nativo, ai requisiti di Industria 4.0.

Maximum transport flexibility with XTS Track Management for machines and production lines. |

XTS, a modular mechatronic kit

In 2012 Beckhoff introduced the XTS system, eXtended Transport System, opening the doors to motion architectures and revolutionizing not only the concept of movement, but also integration on the machine.

XTS does not just replace traditional transport systems, but allows the design of completely new and innovative machines. A modular mechatronic kit can be defined, consisting of track modules of multiple dimensions and radii of curvature by which to compose tracks according to the most disparate profiles.

This leads to a complete integration of the system into the machine, since XTS becomes an integral mechanical part of it. The ability to drive any number of ‘movers’ independently on the same track with a single motion law allows to realize motion applications released from the limits imposed by the typical cycle times of the serial operations that are performed on the same line.

With the introduction of software functionality, XTS offers unprecedented levels of freedom allowing the creation of new machine designs.

Now XTS also supports software-based tool change: packaging shapes and sizes can be changed without manual intervention, avoiding unnecessary downtime.

In fact, production processes often have to stop after completing a certain number of steps, waiting, for example, for the products to polymerize, dry or cool. To avoid interruptions and maintain a continuous production flow, it is possible to create product buffers to feed the next processing station.

XTS Track Management provides the ideal basis for creating buffers, keeping the footprint of the machine to a minimum.