Complete outsourcing for every packaging line

Logimatic is a company providing production services for the mechanical industry, specialised in the construction of automatic machines in outsourcing. It will be present at Ipack Ima 2025 with an offer that ranges from packaging to automation solutions.

Based in Ozzano dell’Emilia (Bologna), in the heart of the packaging valley, 20 years of experience in the sector, 52 million turnover: Logimatic stands out for its ability to develop complete and customized projects on behalf of third parties, producing machines with a complete service.

Managing orders “from a to z”

Logimatic’s approach involves the management of the entire order according to the customer’s requirements, deploying cutting-edge technologies, organization and flexible workflows. In the 12 thousand sq.m. factory that opened in 2019, a team of engineers, technicians and fitters ensures the development, construction and shipment of turnkey lines for various sectors.

In addition, thanks to the contribution of a dedicated technical office, other services are provided, such as the integration of electrical parts into the supply, shipments of components and manuals, logistics and assistance and testing. The logic driving this “services hub” lies, moreover, in the fact that Logimatic is considered by customers as an authentic production and commercial area in outsourcing.

Strategic partnerships supporting innovation

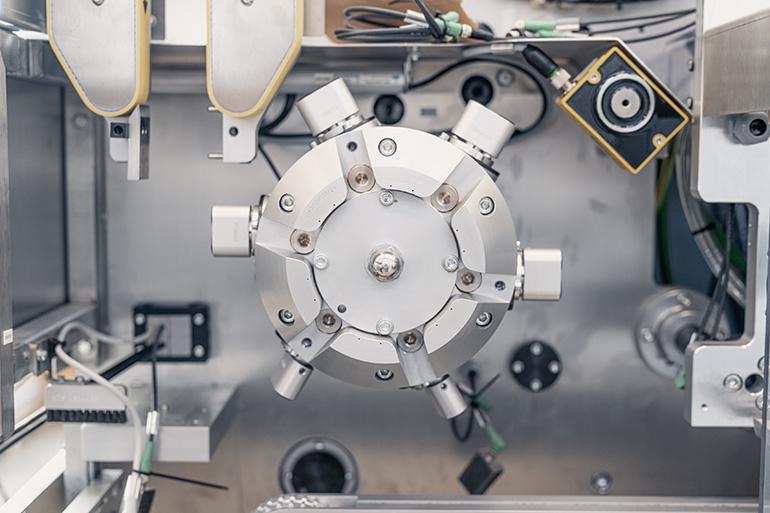

Logimatic has been a production partner of an Emilia-based multinational company for a number of years, together with which it studies, designs, produces and provides solutions to various sectors, ranging from food to pharma, from automation to automotive. For the food division, for example, Logimatic produces filling machines, assembled groups and packing machines for tea bags, as well as high-performance machines for the production and packaging of coffee pods.

The dairy sector is also included in Logimatic’s reference markets, with solutions for the packaging of cheeses and the filling of yoghurt pots.

As regards bakery & confectionary, the portfolio includes flowpack machines for packaging snacks, biscuits, baked products and protein bars. Looking, finally, at the pharmaceutical and medical sector, besides the flowpack technology requested during the pandemic for packaging facemasks, Logimatic makes blister packaging machines integrated with packaging machines and parts of aseptic machines for filling liquids.

Automation is an integral part of the offer

Logimatic focuses on customised solutions for special automation applications such as, for example, contact lens forming and packaging machines and lines for the assembly of tethered caps, as required by the new European Community regulations. Significant challenges, finally, come from the automotive world, to which Logimatic supplies the entire production line of an electric motor, from the unwinding of the copper wire to quality controls.