Closed-loop systems and strategic partnerships for the packaging of the future

At Ipack-Ima – Hall 7, Stand C60 – discover innovative materials and a vision on recycled plastics and secondary raw materials.

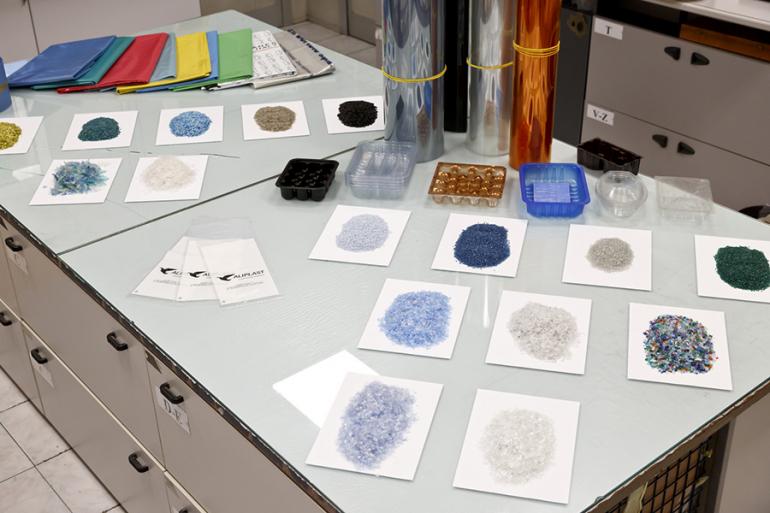

Founded in 1982 as a plastics collection company, Aliplast has grown to become a leader in plastic recycling, specialising in the production of regenerated polymers, rLDPE flexible films and rPET sheets. At Ipack-Ima, Aliplast presents its range of recycled and sustainable materials, developed in cooperation with strategic partners to strengthen the recycling supply chain. This is an industrial sector with the power to transform waste into resources, driven by the development of innovative materials that are increasingly shaping the packaging industry’s commitment to sustainability. Michele Petrone, CEO of Aliplast, talks about this vision and outlines the company's strategy to make recycling a key player across all markets.

Let's start with the Plastic and Packaging Waste Regulation (PPWR), which is now entering its implementation phase.

“For us, the PPWR represents an opportunity,” begins Petrone. “This regulation is directly applicable across all Member States and establishes a uniform set of rules for everyone. It sets clear standards that enable the recycling chain to offer standardised products to a market that is becoming increasingly conscious of its choices, fully aligned with the broader goal of supporting the transition to a circular economy. The PPWR is based on key pillars such as recyclability and minimum recycled content – its 2030 targets are a challenge that must be met. To achieve this, Aliplast focuses on traceability, material origin, quality and machinability. Our goal is to provide customers with high-quality secondary raw materials that meet strict standards thanks to a harmonised regulatory framework.”

Which sectors and countries are most aligned with the new requirements?

“Some sectors, such as those involving single-use plastics, have already begun aligning with the requirements of the PPWR. A concrete example is the impact of the SUP Directive, which mandates a minimum recycled content of at least 25% in beverage and liquid food bottles starting from 1 January 2025. Petrone continues: “Today, the key is to be prepared and to share the commitment to sustainability – one that is environmental, social and economic and capable of moving the system towards a truly circular economy. Standards, controls, consumer awareness and the ability of companies to meet the demand are all essential factors that will influence the outcome.”

Do consumer attitudes and market dynamics change when it comes to sustainability in different sectors?

“Consumers are certainly more attentive today, showing growing awareness and a sensitivity that allows them to recognise the value of secondary raw materials, a value that goes beyond the simple logic of purchase and sale price. Some sectors, such as cosmetics, have already succeeded in conveying the value of sustainability, while others are beginning this journey and need to address key factors in order to achieve sustainable packaging. We're talking about recyclability, large-scale use of recycled packaging waste, and designing products with recycling in mind,” says Petrone. “These are the areas Aliplast is committed to, aiming to meet the expectations of consumers who seek sustainable products from companies that share the same commitment to sustainability. Sectors such as large-scale retail, food, cosmetics, and pharmaceuticals are all embracing sustainability and looking for qualified partnerships capable of delivering advanced solutions that reflect a shared vision. Solutions that treat waste as a resource with the potential for continuous renewal, thanks to an industrial supply chain capable of transforming it. Together with our partners, Aliplast is advancing the concept of product sustainability by generating shared value through the closed-loop model, which is something we have been doing for years.”

Packaging sustainability also reflects geopolitical dynamics, influencing exports. What can you see from your vantage point?

“Protectionist policies can create challenges in sourcing materials, but Aliplast is well-positioned to address this, thanks to the strength of our European supply chain. Our greatest asset is the closed-loop model, where the customer also becomes a supplier, transforming waste into a resource and helping build a national and European recycling market. In fact, we are already established in Poland, Spain, and France and our Italian production facilities allow us to serve the entire European market. In short, while protectionist measures are a concern, we are ready to support our customers with materials that offer documented quality and sustainability. Our logic is, therefore, to present Aliplast not as an isolated player but as part of an extensive network of partners working together to produce sustainable packaging and create a truly circular economy.”

What can we expect from Aliplast's R&D? What directions are you exploring?

“Research is one of our strengths,” says Michele Petrone. “We have R&D teams operating in every plant, with a clear objective to develop materials that convey quality by expressing the concepts of purity and transparency – transforming waste into products that reflect beauty, style and high standards. Our team is focused on the future, seeking new solutions through partnerships with academic institutions and qualified stakeholders. These collaborations allow us to anticipate both technological developments and market trends. The entire process, from collection to recycling and the creation of new materials, demonstrates the development and innovation capacity of a supply chain made up of multiple links in the value chain: Aliplast is one of these links and, indeed, must play a pivotal role in connecting them. The investments we are making position us as a key player in the creation of a new installed recycling capacity. In fact, Modena will become our recycling hub for rigid plastics, particularly HDPE and polypropylene. From this site, we will launch a new range of high-quality materials designed to meet minimum recycled content requirements. This site will embody circular economy model, developed in synergy with the Hera Group, where sustainability is realised through a production process built on the circular use of resources. The new site is part of a well-established Hera Group industrial hub, allowing it to leverage the potential of multiple business lines. In particular, it will be powered by the electricity generated from the nearby waste-to-energy facility, while the production process will use water from the purification plant, which will then be fed back into the process, thus completing a virtuous circle. All of this is being developed in full compliance with the timelines set for flagship circular economy projects, which will be funded through the National Recovery and Resilience Plan (PNRR).”