The word from... Alessio Wagner, General Manager Famar Tec

Always ready for innovation, ahead of the times. Trends and markets: how the way of doing business is changing.

A historic brand in the production of automatic machines for primary and secondary packaging in the pharmaceutical and nutraceutical fields, Famar Tec also has applications in the cosmetics, food and tobacco markets to its credit. Founded in 1969 in Sala Bolognese, in 2015 Famar Tec was acquired by the Curti Industrial Group, active in the engineering sector with a strong business differentiation and already present in the world of both food and pharmaceutical packaging. One of the protagonists of the merging and acquisition transaction was Alessio Wagner, who now holds the role of General Manager of the company.

«We have always been strongly focused on the innovation of our products, and lately we have been focused on the development of more sustainable technical solutions, so as to reduce the consumption of utilities... An example of this is the new integrated blistering line, Connexa 600 (see box), which is the result of an ergonomic design and aimed at minimizing changeover times as well as consumption of electricity and compressed air. We field the ability to intercept market trends such as, for example, the increasing prevalence of oral oncology drugs, which requires blister machines to be equipped with suitable containment systems; not making such systems, we work in partnership with main providers, setting up our machines mechanically and electronically».

«A significant impetus, mainly on the domestic market», Wagner points out, «has been given by Industry 4.0: all our machines are now designed to be interconnected to company systems. We have then developed sw. systems to facilitate the management of spare parts necessary for the correct operation of the machine. Such sw. allow the visualization of machine assemblies directly on the machine’s HMI and the immediate identification of the necessary spare part. An easy drag-and-drop operation makes it possible to compose the cart and proceed with the order to our service department».

Wagner then reflects on the impact of the pandemic and the current geopolitical instability in the way of doing business: «The health emergency first and the war scenarios later forced us to rethink our service model: so we have strengthened remote assistance, now no longer limited to resetting and/or modifying the operation of machines, as well as the way in which we execute machine testing before shipment, in this case adopting new technologies that allow virtual testing, supported by companies specializing in audio and video filming».

From reality to prospects

«Among the most promising outlet markets is undoubtedly nutraceuticals, leading the way in the last five years and growing even more since the pandemic. In fact, it is a less complex market than pharmaceuticals, with rules not comparable in rigor to requirements, but with high margins».

Comforted by the vis-a-vis meeting with the operators who came to visit Pharmintech, Wagner continues to express measured optimism about the future performance of the pharma OEMs: «In a turbulent environment, the packaging industry is generally preserved, and pharma even more so. If, for example, we move toward widespread distribution of vaccines to counter COVID 19 through pharmacies and community medicine, interesting opportunities could open up. I am thinking, in particular, of the distribution of pre-filled syringes or single-dose vials: Famar Tec already supplies machines for the secondary packaging of these drugs, collaborating with world leaders in the production of influenza vaccines.

And again, we are looking closely at what is happening to packaging materials, because the migration to packaging that minimizes the use of plastics in favor of paper and cardboard is a fairly well-established “green” goal, even among pharmaceutical companies. And we will have to be ready, because a machine that handles a plastic material today may not necessarily have to be converted in the medium term to handle a paper material, a composite with a biodegradable, plant-based and limited plastic content. This transition is already taking place in the secondary packaging of products such as syringes, bottles and vials, as it has no impact on the integrity of the product itself. FAMAR Tec has been proposing such solutions for some time now, aimed at the complete replacement of the plastic materials present in this type of packaging. Different discourse concerns the materials used for primary packaging, particularly in blistering processes: the transition to replace the current plastic materials and aluminum will be inevitably slower, having to ensure the integrity of the products until the expiration date».

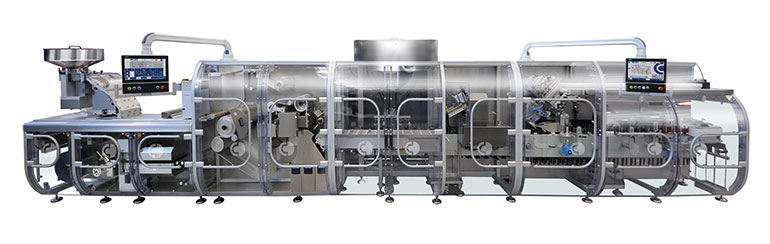

Connexa 600: new integrated blister line

After the launch of the continuous high production cartoner mod. A330C, the process of technological innovation undertaken by Famar Tec continues: on the occasion of Pharmintech 2022 powered by IPACK-IMA it presented the new integrated blister line mod. Connexa 600.

Consisting of a blistering module with roller sealing and a continuous cartoning module, the machine features a robotic system for the positive transfer and stacking of blisters, an ideal compromise between high performance and limited overall dimensions (less than 10 m). Entirely managed by brushless motors and with a balcony structure in line with GMP design standards, Connexa complies with the requirements of Industry 4.0 and allows production of up to 600 blisters/1’ and 300 cartons/1’. The extreme reduction of electrical and compressed air consumption, as well as the simplification of format changeover operations through quick release systems and digital indicators are elements that have guided the design of Connexa 600 from the initial phase.