Monitoring adhesive consumption

In line with the Green Gluing philosophy, the new AMS adhesive monitoring system - developed by Robatech and launched at the end of 2019 - not only ensures cost transparency and reduced glue consumption, but also reliably signals errors in the application process.

Fast and reliable error reporting. The AMS system monitors the actual adhesive consumption during the application process and compares the measured data with the reference values set in the Robatech Control System configuration database; if the quantity used deviates from the defined tolerance range, an error message is issued immediately. The adhesive measurement system therefore improves production sustainability and process security.

All measurement and configuration data are clearly and transparently displayed on the standardised user interface of the Robatech Control System and can be easily exported.

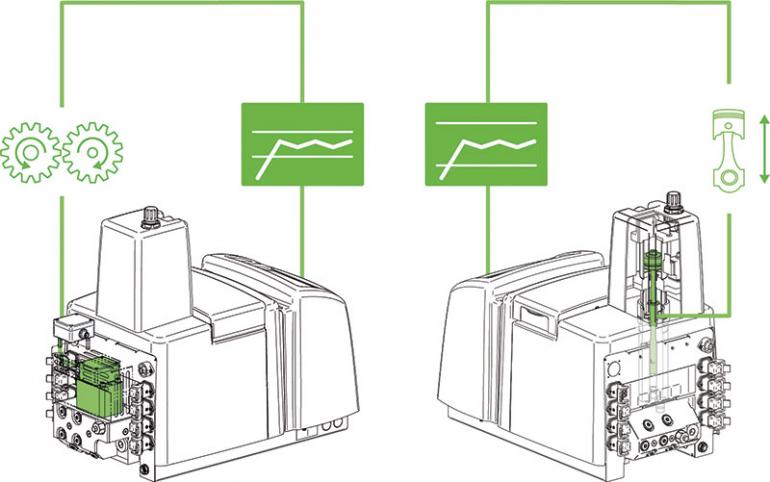

Two models with different performances. The AMS system is available as an option for Robatech’s Concept Diamond and Concept Stream series melters. Depending on requirements, customers can choose between the more economical version with KPC12 AMS pneumatic piston pump or the more precise and faster version with AMS-V measuring cell.