Amarc: curiosity opens the mind

Exploring, investigating and learning is the way to the improve the knowledge and effectiveness of production processes. It’s necessary, however, to know how to how to grasp the changes that are offered, overcoming reluctance to experiment with new proposals… such as cast aluminium electric heating elements for thermoforming and the sealing of trays, as well as the welding of plastic film.

Stefano Lavorini

Repetita iuvant. Knowledge and know-how are founding values of modernity and the denial of complexity can be the beginning of the end of any success story. The most frequent and categorical objection that we often hear repeated is “we have always done it this way and it’s always worked”. But, perhaps, it could be added “not in the best possible way”.

And it’s not even necessary to be driven by the urgency to find solutions to the problems of the moment in order to embrace different horizons. It may be good practice, instead, to start by thinking about current production processes, getting informed, comparing, evaluating and perhaps trying out what the market has to offer and for which there hasn’t yet been the opportunity to experience.

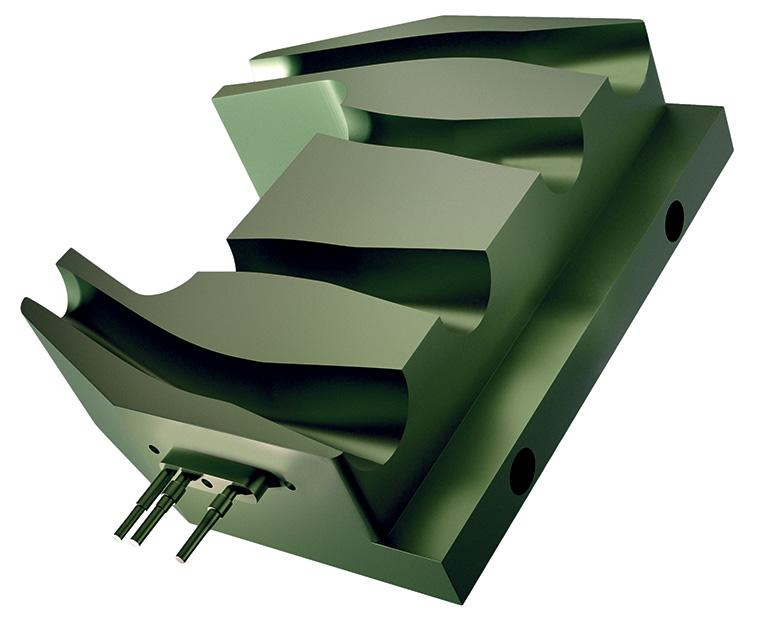

Giorgio Ardesi, who, together with his cousin Andrea, manages Amarc, the company founded by his grandfather, specialised in the design and development of products and solutions for the heating and transformation of materials in industrial processes, is totally convinced of this. Responding to my questions, Ardesi underlined how, by tradition and conviction, doing business means, most of all, operating in a transparent and correct way: a principle which, in the case of cast-in heaters, components of the hot part of packaging machines (forming - filling - closing (HFFS and VFFS) and thermoforming machines), involves challenging research work, aimed at identifying and measuring the particular advantages of this technology.

In other words, it seems that, in Amarc, they are always ready not only to solve problems, but also to compare and discuss on a technical level “what could be but isn’t yet”.

How do cast-in heaters differ in terms of performance compared to other heating systems?

In general terms, compared to cartridge and wheel heaters, to flat heaters in mica or silicone rubber, plates with embedded armoured heaters ensure superior durability, reliability, efficiency and safety: interesting pluses for machine manufacturers and for end-users.

In addition, they offer excellent electric insulation, also in severe conditions, and a uniform temperature throughout the surface, with the advantage of a single electric connection, regardless of the size.

Based on our experience and on feedback from customers, electricity consumption falls significantly and, thanks to high mechanical properties and corrosion resistance, they are guaranteed to be longer-lasting compared to other technologies, with a consequent significant reduction in technical maintenance interventions.

An interesting picture for sure. Do you have data and details, however, that allow potential users to make precise comparisons?

The results in the field collected in the last few years confirm the points of strength of the heaters within the aluminium casting compared to other heating systems; nevertheless, in collaboration with an external research centre, we are carrying out trials and tests in order to better detail and quantify the advantages we are able to offer with this solution.

A number of users, for example, have informed us that, in operating conditions, an efficient and uniform transmission of heat is obtained with our plates, with a resulting reduction in the time necessary to reach working temperature.

Are you carrying out other research and development activities?

Our technical office is implementing CFD (Computational Fluid Dynamics) analysis methods, for the design of special installations, that make it possible to predict the heating temperatures of our cast-in electrical heaters.

Given these performances, it is easy to imagine that the cost of heating elements is proportionate and therefore higher than other better-known solutions. Is that right?

All our products are characterised by high-level engineering and technology and are designed to guarantee simplicity of use, high thermal efficiency and maximum operating safety.

In the case of cast heating elements, we are convinced that the benefits clearly outweigh the higher purchase costs of the components, being only one of the elements of TCO (Total Cost of Ownership): acquisition, installation, management and maintenance.

What does this mean in practice?

Let’s take, for example, the fact that the heating element is “embedded” in the plate: this means there is no heat exchange with the air, thereby ensuring greater durability over time, and that is, a drastic reduction in machine stoppage – whether involving thermoforming machines, tray seals or flowpacks – as well as significant energy saving. But that’s not all. A single heating element, which exchanges heat in safety inside the cast aluminium, offers the advantage of having a single electrical connection, thereby simplifying maintenance, a guarantee of temperature uniformity over time also on large plates, and, last but not least, greater safety for operators, who cannot accidentally come into contact with the heating element.

Who are your customers?

We mainly work with manufacturers of automatic machines, in Italy and in a number of European countries, who are positioned in the medium-high end of their markets. They are companies that offer high-productivity solutions, which means they well understand what it could cost for their customers to face production line stoppages, and who therefore seek to minimise this risk and the consequential repercussions.

For our part, we offer our experience to define in collaboration with our customers the most suitable features of a product, taking action, for example, on the characteristics of the aluminium alloy, on the type of casting, on the surface treatments in order to improve anti-stick properties qualities and smoothness or to reduce abrasion. In conclusion, we are ready to be put to the test…