Simply the best

The advantages of the cast aluminum or bronze heating elements on packaging machines: ease of use, high thermal efficiency, and maximum functional safety. Amarc’s know-how serving the market.

Stefano Lavorini

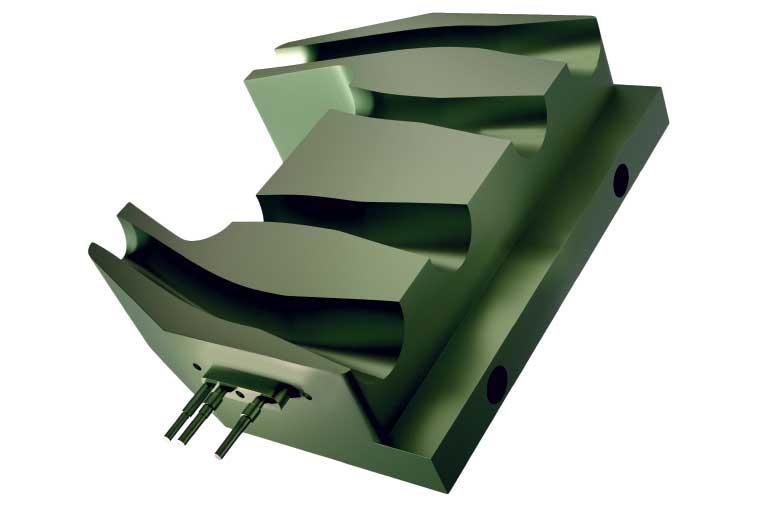

Cast aluminum or bronze heating elements are a component of the hot part of forming - filling - closing (HFFS and VFFS) and thermoforming machines. The ones produced by Amarc can represent an advantageous choice compared to the traditional electric heaters, used on thermoforming and tray sealers, as well as sealing of plastic films.

The difference, again, is in the details. Data in hand show that plates with embedded armoured heaters offer excellent electrical insulation - even in harsh conditions - and uniform temperature over the entire surface, with the added advantage of a single electrical connection, regardless of size.

They also allow a significant reduction in power consumption (-30%) and, thanks to the high mechanical properties and resistance to corrosion, ensure a longer life than other technologies, resulting in a drastic reduction of technical maintenance.

The cast-in heaters produced by Amarc are the result of decades of experience in designing and manufacturing solutions for heating and transforming materials in industrial processes.

«All our products are characterized by high engineering and technology and are designed to ensure ease of use, high thermal efficiency, and maximum functional safety» Giorgio Ardesi declares, who with his cousin Andrea, runs the family business founded by their grandfather.

To each his own

Amarc manufactures cast heating plates according to customer specifications, shaping and machining them with CNC machines; these plates can reach temperatures of over 300 °C and can be prepared for electrical connections in housing with IP55 and IP65 protection.

In the case, for example, of HFFS (flow-pack) machines, cast-in heaters have been developed for cross sealing of the packaging film.

«For decades we have been partners with a leading global company, with thousands of installations worldwide - as the technical manager, Umberto Riboldi, points out - and we have not encountered any problems with weld sealing with any type of plastic material, including the new biodegradable polymers or those from renewable sources».

Free sample to test the advantages of the heating elements

Amarc is a customer-oriented company, which means, for example, that they do not have a catalogue but the technical office works alongside the customer to choose the most suitable solution for each individual application.

«As far as heating plates are concerned - Andrea Ardesi is clear on the subject - we well understand that machine manufacturers may be reluctant to experiment with new solutions, and therefore, precisely for this reason, we are committed to providing, to those who request it, a free sample to make a test and an initial assessment».