Efficiency, speed and reliability with SMC solutions

A cutting-edge partner for an increasingly sustainable packaging industry.

Since 1959, SMC has been synonymous with innovation in the field of pneumatic components for industrial automation. With 12,000 basic products and more than 700,000 variations, from air treatment to instrumentation, valves and actuators, it offers cutting-edge solutions for the Automotive, Electronics, Food and Life Science industries. The packaging industry SMC operates in is constantly called upon to respond to increasingly complex challenges, dictated by stringent regulations on packaging, product protection, traceability and sustainability that drives research into design and new materials.

Advanced solutions for secondary packaging management

In such a dynamic and competitive environment, secondary packaging – which includes operations such as Pick and Place, palletizing and preparation for distribution – plays a strategic role in ensuring a continuous, efficient and optimised production flow. In this context, SMC is a technology partner of choice, offering components and systems designed to maximise productivity and reduce operating costs, making safety, reliability and innovation its keywords. The SMC range includes gripper systems, pads and ejectors, all designed to meet the specific needs of modern packaging lines.

The ZP3C pad

One of the company’s most versatile products, the ZP3C pad stands out for its ability to efficiently transfer abrasive materials such as cardboard. Available in flat versions with ribs, both with bellows and with diameters from 40 to 50 mm, the ZP3C guarantees excellent resistance to wear and tear and significantly reduces maintenance costs. These features make it the ideal solution for Pick and Place applications and packaging processes that require reliability and consistent performance even in the most intensive cycles.

ZGS vacuum gripper system

For applications where compactness, integration and speed are key factors, SMC offers the new ZGS vacuum gripper system, an all-in-one solution that can be perfectly integrated with industrial and collaborative robots. The modular design simplifies installation, reduces start-up time and facilitates maintenance. The system includes a compact ejector, foam, supply and release valves, pressure switch, M8 connector cable for quick connection and a direct pneumatic supply. ZGS redefines efficiency in palletizing operations.

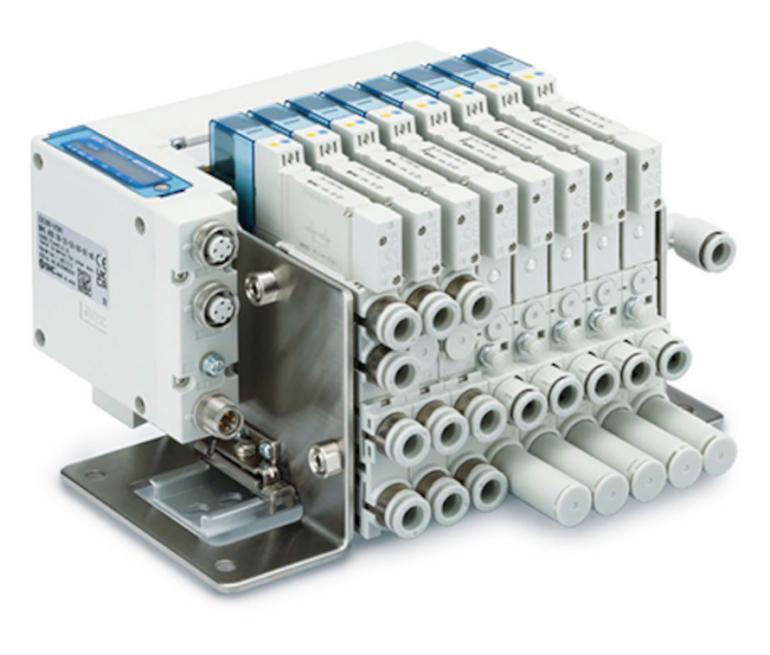

ZKJ ejectors

For more complex requirements, such as vacuum transfer systems, automatic assembly machines, packaging and unpacking lines or panel conveyors, SMC offers the ZKJ vacuum manifold, a high-performance solution with integrated control. Its architecture enables the simultaneous management of up to 16 ejectors through a single device, integrating fieldbus communication and ensuring high energy efficiency. Thanks to its compact design and single-side connection integration, the ZKJ fits perfectly into even the most demanding working environments. Through this range of advanced components, SMC provides practical support to industry players in improving productivity, efficiency and sustainability.