Innovation and excellence in industrial packaging

Gampack has been a leading player in the secondary and tertiary packaging industry since 2003, thanks to a wide portfolio of turnkey solutions and a solid international presence. In anticipation of Ipack-Ima 2025, where Gampack will be displaying its systems, we present a preview of the company’s development strategies.

Innovation, professionalism and attention to the customer are the values that allow Gampack to be a point of reference, in both the Italian and global markets, for the development and production of technological solutions for secondary and tertiary packaging. With over twenty years of experience in packaging automation, the company further extended and strengthened its expertise in robotics technologies in 2020 thanks to the acquisition of a renowned Italian company. This was a decisive step, allowing it to operate with success in many industries: from food&beverage to cosmetics, from pharmaceutics to pet food and many more. Led by the co-founder and Chairman Giuseppe Gazzola, and assisted by a motivated management team, Gampack pursues a growth and innovation strategy oriented towards the future, which sees R&D, AI and sustainability as key drivers for growth.

Innovation in the DNA

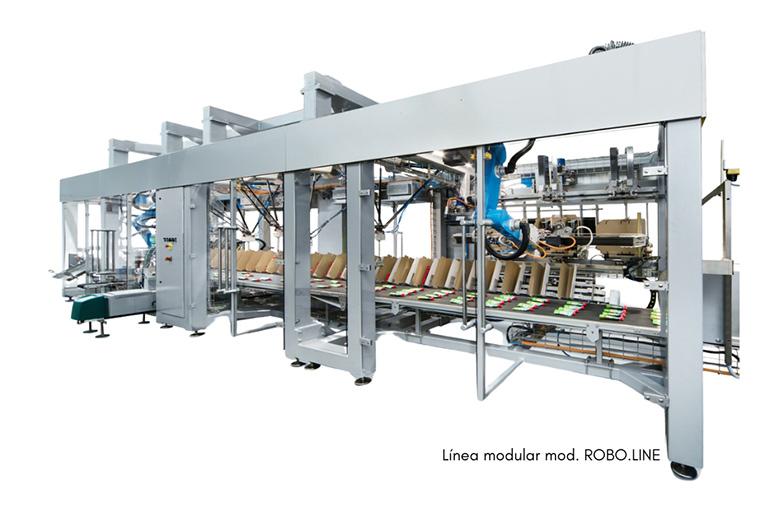

Therefore, Gampack is pecialised in the design and production of advanced systems for secondary packaging and palletisation. There are two key aspects of its offer: on the one hand, the development of automatic machines meant to pack different rigid products, such as beverage cartons, cans and glass jars. On the other hand, the company’s drive for innovation is reflected in the work of its robotics division, which integrates the traditional range of machines for secondary packaging - forming, closing and clustering machines, etc. - with robotic systems designed to provide highly customizable complete solutions, suitable for packing both rigid and flexible products such as doypack, flow packs and pouches. As matter of fact,flexibility is a cornerstone for Gampack, with machines designed to adapt rapidly to different packaging dimensions and production parameters,enabling the company to offer turnkey systems, designed to meet each customer’s needs. With over 1,500 installations worldwide Gampack guarantees excellent aftersales service, standing out from its competitors for its ability to take swift action and provide spare parts within 24 hours, ensuring operational continuity even in the most complex situations.

Advanced technology and future oriented sustainability

Gampack’s intense R&D activity is increasingly focused on artificial intelligence (AI) in packaging systems. In fact, through the analysis of production data and the optimisation of processes AI increases efficiency, prevents errors and reduces waste, improving both productivity and the working environment of operators. Moreover, in terms of sustainability, Gampack has embraced eco-friendly production processes, creating innovative packaging solutions such as clusters, Mini-trays, I-layers, and Eco-labels, all crafted from renewable, biodegradable, and recyclable materials. A commitment to environmental responsibility, combined with production efficiency, is increasingly valued by customers and has become essential for meeting the ambitious demands of a competitive and ever-evolving global market.