The IMA Group at Achema 2022

The IMA Group is pleased to announce that its Pharmaceutical divisions will be present at Achema 2022 to show the All-In-One Pharma range of solutions and the following projects aimed at sustainability and digitalisation.

IMA ZERO is the evolution of the Group’s commitment to Sustainable Development. Its ultimate goal is minimizing environmental impact in industrial manufacturing and promoting a working habitat that always puts people at the centre. At Achema, visitors will discover No Plastic solutions in the pharmaceutical field and a dedicated IMA ZERO workstation focused on the IMA Group’s development in the sustainable pharma field and on all practices implemented by the Group, together with its customers and partners, to minimize environmental impact in industrial manufacturing.

OPENLab, part of IMA ZERO, is the Group’s network of technological laboratories and testing areas, dedicated to research on sustainable materials, technologies and production optimisation processes. Through the research and testing of alternative processes and materials, together with our partners, we foster plastic-free and sustainable, compostable or biodegradable packaging solutions. In the period 2017-2021, over 3,800 film structures were analysed in the laboratory and over 400 films were tested. In the IMA ZERO workstation at Achema, it will be possible to discover part of our material database and meet our material experts.

Visitors will also have the chance to discover IMA Digital, the global project aimed at enhancing production and operational activities through a wide range of digital tools and virtual applications, starting with connected machines powered by artificial intelligence, and landing on APPs and devices for advanced maintenance and training. IMA offers end users a series of ancillary Digital Services and a wide range of solutions that integrate platforms and tools covering the needs of 360° Digital training.

The new machines on show

IMA Active, specialist in Solid Dose solutions, will showcase ADAPTA 50, the new compact capsule filler that combines IMA’s unrivalled experience with the most innovative technologies for quality control. While designing this machine, IMA Active scouted for new technical solutions, improved the handling of difficult products, tested innovative algorithms and feedback loops to enhance the in-line control of critical quality and performance attributes. Also on display, the Continuous Manufacturing corner to discover how to achieve the most appropriate configuration of a Continuous Manufacturing line, combining process, equipment design with risk analysis. IMA Active proposes Continuous Manufacturing lines for compression, coating and encapsulation of OSD forms as a single partner of integrated solutions based on flexibility and modularity.

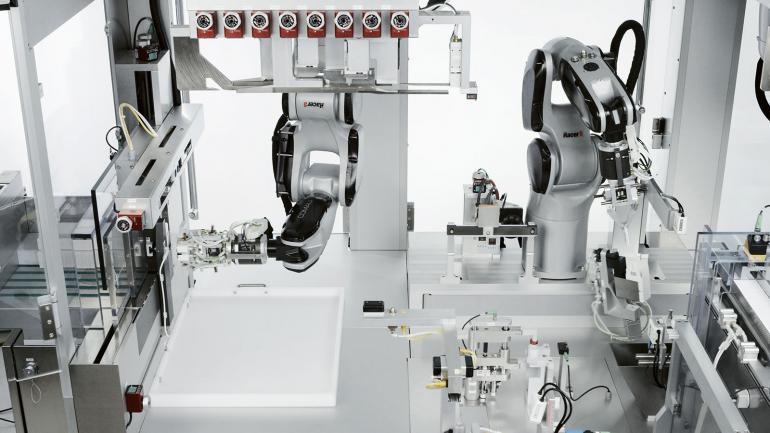

IMA Life, the Aseptic Processing & Freeze-Drying Solutions division, will present as a world premiere INJECTA 36, the high-speed, advanced robotic processing for Ready-To-Use syringes and pre-capped cartridges. Also on display, Xtrema, high speed filling and stoppering machine for aseptic environments, Sterifill RS, fill-finish solution for Ready-To-Use components, and, at the Lab4Life lyo corner, the Lynfinity Lab, laboratory spray freezing module and the Quantum, smart miniature mass spectrometer. At the LAB4LIFE lyo corner the company will also introduce the KryoAir, the new totally green technology for air compression refrigeration and the Sentinel LYO, cloud-based platform for freeze drying data analysis, system health monitoring and predictive analytics.

IMA Safe, the only manufacturer that offers complete primary and secondary packaging and end of line solutions, will present TRIT-ONE, the revolutionary robotic cartoning island for packing small high-value product batches and the VERTICARE P, a vertical cartoner equipped with innovative devices for smooth and gentle processing of highly sensitive, fragile or specially shaped products.