IMA SpA - BFB Division | Best Packaging 2022

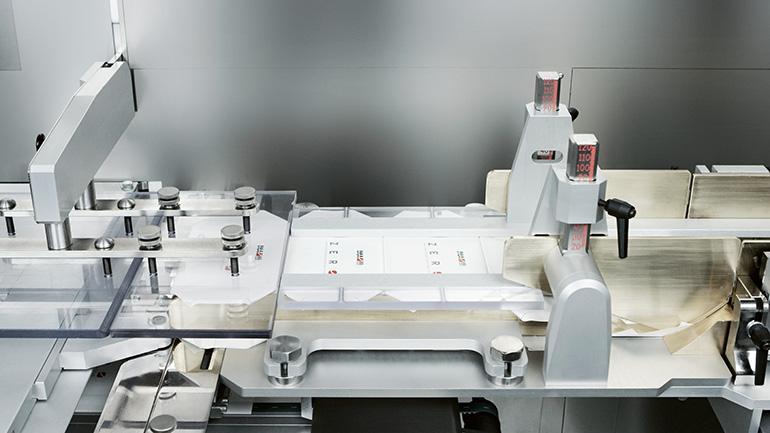

HYWRAP20 wrapping machine

balanced | responsible | sustainable | contemporary | safe

What it is. The IMA BFB HYWRAP20 wrapping machine is designed and built to operate at medium-high speeds, guaranteeing extreme precision, a high level of quality and the possibility of using sustainable materials. Starting from its name, HY(BRID)WRAP, features as a hybrid and flexible solution, suitable for wrapping with paper, traditional plastic material (OPP), compostable and recyclable film, without the need to change the configuration or the components according to the treated material. In the case of wrapping with paper, the machine does not require external gluing units with spray guns, reducing energy consumption, maintenance and the amount of glue required for sealing. In fact, the dispersion of adhesive on the sheet is avoided, favoring its recyclability, and there is no need to store bags of glue, supplied in the form of tablets that must be heated and melted to be used.

Materials. Paper on which a minimal amount of glue is incorporated; recyclable clear BOPP film; compostable film.

Product or target market. The wrapping machine has been designed as a transversal model, reconceived in its functions and design. The great choice in the set-up, with a wide range of optional units, allows it to address different sectors, from cosmetics to food or pharmaceuticals.

Design and/or communication. Thanks to the synergy between BFB and OpenLab - the network of IMA Group laboratories, with researchers specialized in the chemistry of materials and related test areas, which participated in the studies for the realization of the wrapping machine - the most suitable material for the product and the target market is identified, to ensure maximum protection of the content, the aesthetic appeal of the final package and sustainability.

Technology. Together with OpenLab, tests were carried out on different types of paper to study their behavior and identify the minimum surface area necessary to incorporate the glue for closure. The glue, already present in specific areas, is incorporated in minimum quantity (about 5% of glue quantity on the total surface of the sheet) only in the areas where the flaps are glued for the closure of the pack. Tests have also been carried out to minimize flap sealing and cooling times based on paper type, and lower consumption accordingly.

Sustainability. The machine facilitates the use of compostable and recyclable materials, both paper and film, since it does not need to be equipped with special units and does not require changes of pieces per format when the wrapping material changes.