Marchesini Group at Achema 2022

On show integra 720v for the serialization and aggregation of blisters.

One of the most eagerly awaited world chemical, pharmaceutical and biotechnology events is back: from 22 to 26 August, the Frankfurt showgrounds will host the 2022 edition of Achema, postponed again from April to August due to the pandemic.

At this exhibition, which brings companies from more than 50 countries together every three years, Marchesini Group will be presenting a wide selection of machines and lines developed for the pharmaceutical industry with innovative features in the areas of Industry 4.0, sustainability, safety and product traceability.

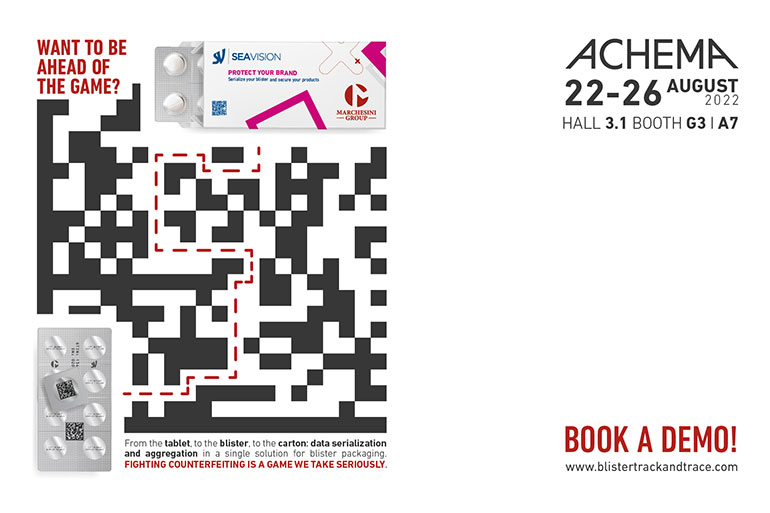

In centre stage on stand G3 in hall 3.1 will be a state-of-the-art solution for the packaging, serialisation and traceability of blister products, developed in association with strategic partner SEA Vision - a company specialising in vision systems.

Lines on show

INTEGRA 720V, a robotised integrated line for packaging blisters in cartons, will be presented with BL-A525 CW labelling machine complete with incorporated checkweigher for dynamic weighing and control of cartons. What makes this line innovative is the inclusion on board the machine of a new technology, unique on the market: a complete software package that aggregates the blister to the carton.

This is a strategically important solution for all contexts where blisters are sold, distributed or separated from their original pack, whether by the end user or by other players along the distribution chain, such as in hospitals, or in pharmacies in many countries. Although regulators do not yet require the serialisation of individual blisters, this technology is intended to provide suppliers with an added opportunity for protecting consumers and combating the counterfeiting of pharmaceutical products, preparing for the future and its demands in advance.

The INTEGRA line will be further equipped with the Predictive Maintenance solution developed by the Marchesini Group. The data of the sensors installed on board the machine (IoT) is collected, analysed with the aid of Artificial Intelligence (AI) algorithms, transformed into information useful to the operator and displayed by means of a dedicated web platform, on display at the show. Checking this information will enable anomalies to be identified and maintenance to be scheduled in advance, avoiding any failures.

In addition to this new technology for solid products, the Group will also be exhibiting two more innovative lines for the inspection and packaging of products in stickpacks. First of the two, visitors will be able to view a line consisting of a CMP Phar.ma inspection machine checking 400 vials per minute: thanks to innovative inspection systems based on Neural Networks and Artificial Intelligence (AI) technology, the new machine upgrades performances, maximising flexibility and precision.

The line is completed by an RL-F800 extremely high-speed labelling machine with a rotary star wheel infeed system and rotary roller conveyor, designed by the Neri division, and a TM3 for bundling vials in trays, with counter function. On board the line, SEA Vision cameras will provide optic control of tray contents.

Secondly a line for packaging products in stickpacks, comprising a Schmucker MT1300 12-lane stick packaging machine, a stacking and counting system and an MA80 cartoner. Specifically, this line is designed to process PP-based packaging materials (with and without PE) such as 100% recyclable plastic monomaterials like OPP or BOPP with a metallised intermediate layer.

This solution reflects the Group’s commitment to expanding the range of solutions which use sustainable packaging materials, and forms part of the broader new “Be” project on environmental, social and economic sustainability.

Stand-alone machines on show

Three stand-alone machines will also be exhibited, including FSP05, an automatic solution for filling and stoppering RTU (Ready to Use) vials, cartridges and syringes in nests. This machine, produced by the Corima division and already consolidated on the market, is presented with a new filling technology using “disposable volumetric pumps” developed by Neoceram in association with Marchesini Group. FSP05 can also be configured with other dosing systems, such as the standard rotary piston pumps, both in CIP/SIP version and in autoclavable version, and with peristaltic pumps.

On show will be also a TURBO-MEK 1000, a vacuum turbo-emulsifier for processing liquid products, developed by Dumek, the Group brand specialising in processing solutions for pharmaceutical products. The machine, designed in accordance with hygienic and cleaning design guidelines, is extremely flexible and is ideal for processing a wide range of products, since it is equipped with an internal turbine and a second turbine for the external recycling of the product. This solution also features SMART TC, an intelligent system patented by Dumek which not only favours energy savings during the heating and cooling stages, but more precise control of processing stages too, ensuring greater repeatability.

Last but not least, the stand will host a solution by Dott. Bonapace, a company based in Cusano Milanino (Milan) that became part of the Marchesini Group in 2021, which specialises in laboratory machinery and in small industrial production outputs of high-tech pharmaceuticals and for Research & Development. The machine displayed will be the IN-CAP SE automatic filling machine, able to process up to 3,000 capsules an hour and designed to dose various products (such as powders, liquids, pellets and tablets) into the same capsule, with over twenty possible combinations.