Smart capping systems for an increasingly sustainable packaging

Data gathered in real time, digital twin, data analytics: AROL’s R&D team has directed its developments towards an increasingly digital capping, to allow its customers to manage the bottling line in smart mode, with the objective of increasing the overall effectiveness of the machinery and to reduce maintenance and production costs.

Arol at interpack | Hall 13 - A93

In this way, optimising the use of resources, it will be possible to produce in a more efficient way and achieve high levels of sustainability. There will be many innovations displayed at Arol’s stand.

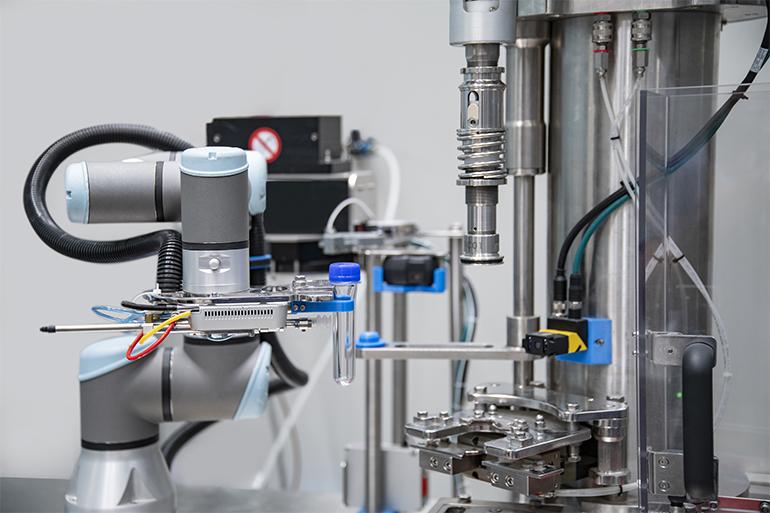

First of all, there’s ClosureXpertLab, developed to perform capping tests automatically, independently picking up capsules and preforms and assembling them. The system measures the environmental and dimensional characteristics, the application torque, the removal torque (immediate or deferred), with the objective of reducing the ramp-up times for implementing a new product. There will also be a wide range of intelligent “instrumented” bottles that can be used both off and on running production lines. They are bottles that send data via bluetooth wireless, designed for the measurement of data such as the lateral load transmitted by the thread/seamer rolls and for measuring the axial load transmitted by a capping head.

The completely electronic EQUATORQUE IQ EVO capper, finally, is equipped with a device able to collect temperature and vibration information on every capping axis and communicate it by radio frequency to the automation of the machine or to SMART CLOSURE, Arol’s data collection and analysis system.