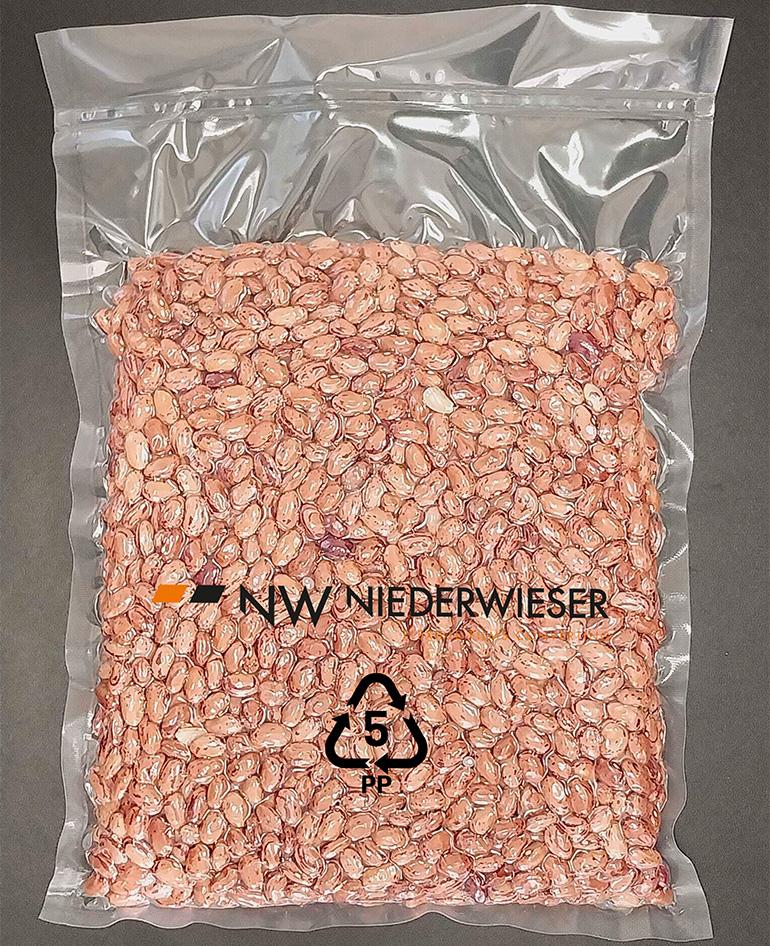

Niederwieser SpA | Best Packaging 2024

Combivac Nextflex monoPP

What is it. Customizable and recyclable vacuum pouch suitable for cooking, any kind of food.

Accessibility focus. This pouch offers exceptional user-friendliness: it only needs to be opened, filled and sealed, either vacuum or in MAP (Modified Atmosphere Packaging). Since the pouch can be printed, high levels of customization can be achieved. Labels can display a lot of information (instructions for use, ingredients, nutritional tables, etc.) and can also be in multiple languages. By adding optional features, such as pre-cut for easy opening or the euro hole, it can be considered even more user-friendly.

Manufacturing material. PP (polypropylene); BOPP film + polyurethane-based inks if printed + Polyurethane adhesive + Coex film PP-EVOH-PP.

Technology. Rotogravure or flexographic printing machine + lamination machine (+ cutting machine, if necessary) + heat sealing machine.

Product and potential markets. Originally developed for the food sector but suitable for other non-food sectors as well. The packaging can be used for heat treatment, up to sterilization at 121 °C for 1 hour. Perforating food products and/or applications at low temperatures (below 0°C) may represent a limitation.

Design & Sustainability. Available in two sizes: rectangular and flat, two-dimensional (width x height) and Tetrahedral with gusset, three-dimensional (width + depth x height). The pouch holds a recyclable certification (by Cyclos), underscoring a dedicated commitment to environmental conservation.