Emotions around finishing

From chrysalis to butterfly. This happened in Faenza, Italy, last June 22 and 23, when philosophy and the state of the art of finishing intertwined in a full immersion full of technical information, colors and flavors that was able to show the new course taken by Prati, the protagonist of a cultural and technological metamorphosis. Voices from a very special open house, under the sign of collaboration between companies.

Edited by Daniela Binario

Those who attended “The Digital Experience” open house went home with a lot of details about digital and analog finishing dedicated to label and packaging printing and the steps Prati is taking towards 4.0 and sustainability, but also with a wealth of emotions that gave a good idea of the atmosphere at the company.

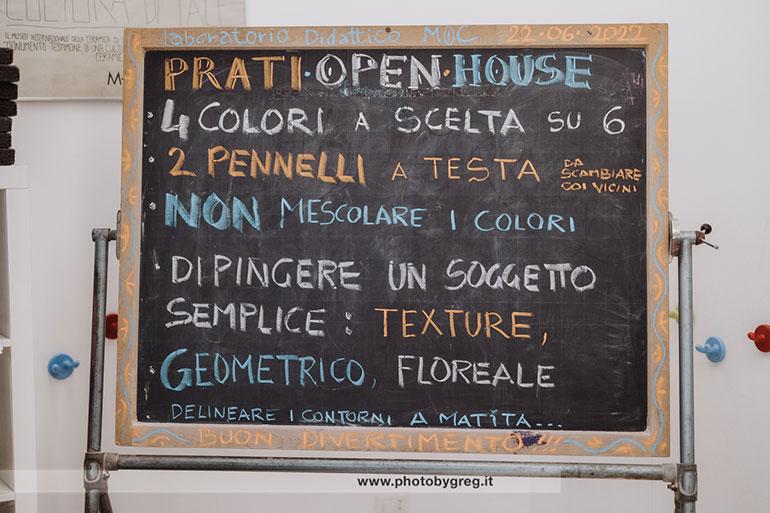

The dinner in the picturesque setting of the garden of the Museo Internazionale della Ceramica, the toast of the employees who shared the joy of that moment together with suppliers, customers and Annalisa and Chiara Prati, and the live music that then involved the guests until the end of the evening. But there were also tangible memories: a bit of practice in the Museum’s workshop to unleash one’s imagination and paint a custom tile and the limited-edition bottle of wine embellished with the label created by packaging designer Mario Di Paolo.

Technology in action

During the event, Matteo Bertoni (area manager and DIGIFAST20000 product leader Prati) had the task - brilliantly done - of illustrating the potential of the various machines even to foreign customers connected via live streaming.Below are the strengths of the “made in Prati” models as seen through the eyes of users and some notes from component suppliers.

Limitless creativity

«Our customers - explained Matteo Bertoni - were asking us for a ‘non-stop solution’. And here is the DIGIFASTone, fully digital, both in finishing and die-cutting for short runs of promotional labels. It requires no special tools for machine startup and ensures fast set up, thanks in part to the laser die-cutting unit, which offers the huge advantage of not imposing limits on label size and shape. In addition, the twin-shaft turret, in combination with the buffer, ensure non-stop rewinding. And the operator no longer has to worry about which material he should use, because the machine knows. Its job is limited to loading the cores and retrieving the finished reel».

And it was DIGIFASTone that allowed designer Mario Di Paolo, who is used to “bending” technology to his needs, to express creative genius in designing the label for the limited edition Leone Conti di Faenza white wine, delivered as a gift to guests.

Using completely recycled cotton paper from UPM Raflatac, the challenge, in this case, was to devise an original shape that, together with a play of transparency, color and gold, could communicate the metamorphosis taking place in the company and thus convey the meaning of the event: the evolution of Prati “from chrysalis to butterfly.”

«Very often - Di Paolo commented - it is precisely thanks to machines that we are able to do unimaginable things: all we have to do is understand how they are made and how they work, and everything becomes simple. This was also the case with Prati when, hand by hand, I was learning from Chiara about the potential of each machine and the infinite possibilities that opened up for me in terms of processing and ennobling».

«Our collaboration - pointed out Chiara Prati, the company’s sales & marketing director - began a couple of years ago when we involved Spazio Di Paolo and UPM Raflatac in a special project, using the “booklet” machine, which can make a label by performing material layering. We hope that the synergy created for The Digital Experience event is just the beginning of a fruitful path for all of us».

The plus of flexibility

Of the “newborn” DIGICOMPACT, numerous qualities have been recalled by Andrea Canini di Vignoli. In addition to optimizing the footprint, it is the ideal choice for those who aim for extreme process flexibility. In fact, the modular design allows for quick changeover from roll-to-stack to roll-to-roll configuration, making it perfect for those who need to produce not only rolls but also cut-and-stack labels or sheetfed jobs. A variety of label formats can be reproduced and it uses a single stacker for all formats. (Chiara Prati spoke about this “new born” in a video interview made by ItaliaImballaggio - Packmedia, Ed.).

Space for paperboard converting

DIGIFAST20000 - Bertoni explained - was designed to meet the needs of a growing digital market, and was born from the collaboration with HP for the HP Indigo 20000 and 25000 model.

With a 760-mm roll band, it is suitable for the mid-web and can do various types of coating (spot or full), with UV or water-based technology, and the drying system does not require coolers.

It can be set up in roll to stack or roll to roll configuration, and the type of coating module, which is also needed later, can be added.

In roll to stack configuration, and by combining flat die cutting, creasing and fold gluing, on this machine it was possible to create the small promotional boxes distributed during the meeting, with delicious chocolates.

«The synergy with Prati - commented Marco Murelli, HP’s L&P account manager - has made it possible to offer a unique solution for papermaking, and by using the printing module both offline and online, the needs of different markets, food and non-food, can be met».

Productivity on long runs

“Designed to run” on long runs as Bertoni called it, the Vega+, on the other hand, is ideal for those who need to produce high quantities of labels of a specific layout: the process of cutting, rewinding and closing the finished reels is done automatically.

«With the Vega+ we have increased productivity by 40%, appreciating its safety, high quality and FASTCUT» commented Manfred Pichler of Logett GmbH, a company to which the eighth Prati machine will soon be delivered.

He was echoed by Alessandro Farinella of Raining Labels, a Prati customer since 2006. «We have three Vega models in operation and the one on display at the open house bought recently. The reason for the choice? The seriousness of the company. Decisive is the possibility of mounting reels exceeding 4,000 linear meters (processed in 25 m/min), and the reel change in 5 minutes. Another important advantage is the possibility of deciding where to cut the material».

Zero-defect labels

Giovanni Beretta of Carlo Volponi Sa and Karoly Orban of Codex Zrt served as testimonials to SATURN Bidi.

«Prati’s strength? Knowing how to keep up with customers. The biggest ‘flaw’? Their machines always run well!» Thus commented Giovanni Beretta (production manager of Carlo Volponi Sa), who has been using Prati machines for 35 years.

«For our label production, we were looking for a solution that offered greater safety and error reduction. With the SATURN Bidi we have been able to avoid manual inspection checks, and the labels produced are ‘zero defect.’ If anomalies are detected, the machine stops bringing the job back to allow the operator to fix the defect shown by the camera. It can process standard or booklet labels, and the optional FASTCUT device, which places the knife in the correct spot, has enabled us to further reduce job changeover times».

The ability to perform bidirectional defect inspection also makes this model popular in the pharmaceutical industry.

A look at the components

A refresher moment from some suppliers as well.

Massimiliano Lombardi of Decosystem explained how Sentinel systems work, enabling inspection to be carried out in different sectors, particularly for cosmetics, and on various materials (labels, narrow-band work and transparent or opaque materials).

Roberto Maiocchi of BST Eltromat Italia, on the other hand, explained how their inspection systems are increasingly moving toward the Smart Data philosophy, which “closes the loop” to transform data into useful information. In fact, data is collected in a central unit and distributed from there to create less waste and enable linkage between systems from different manufacturers.

Future and innovation

«The word DIGI in the name of the machines - explained Mirco Palomba, Prati R&D manager in his speech - communicates the direction in which innovation is traveling. Our intention is to take a step forward following the dictates of Industry 4.0, starting from what it is today (a collection of machine usage data linked, for example, to a recipe or the setting of certain parameters) moving toward more usable, readable and interpretable data so as to offer a competitive advantage to the end user».

Among the digital services offered on Prati machines should be mentioned FASTLANE, a real database that records history, alarms, interventions, and gives insight into machine status and operation.

Then to solve the long-standing shortage of super-skilled operators, Prati is working on another pivotal concept, usability.

«We have succeeded in decreasing the learning time to get to know and start the machine, and we do this by “guiding” new operators step by step on the machine, in the name of maximum safety. And since tomorrow’s operators are the kids who study and play in digital worlds today, we are adopting the concepts of gamification to make ourselves better understood. We are convinced that going along with these changes, including providing statistical usage data, is the best way to grow and grow skills».

Sustainable together

Finally, Enrico Gardegni and Carlotta Innocenti, Prati’s QHSE Manager and QHSE Specialist, respectively, explained how the company is moving to achieve sustainability goals starting with the machine design processes and thus be ready for the transition to the circular economy.

In December 2018, Prati obtained its first certification (UNI EN ISO 14001:2015), but the focus on the environment began as early as 2014 with Treedom, and will continue in the future with a commitment to various projects toward decarbonization, to be shared with suppliers and customers to keep up with a changing world.