The European robotics market has a new player

Finding out about Jaka Robotics with country manager Giacomo Mariotti, who focuses on its arrival and expansion in Italy.

Maria Costanza Candi

Just Always Keep Amazing: this is the meaning hidden in the acronym making up the name Jaka Robotics, a spin-off of the University of Shanghai founded in 2014 to create wonder and which today has more than 10,000 robots installed throughout the world, 600 employees and a German branch, in Nuremberg, which performs the fully operational role of headquarters for the European market. The company motto, “free your hands”, tells of a mission that views robotics as a unique tool for collaboration with people, to relieve the burden of repetitive and tiring tasks which also have low added value.

Exponential growth and high-end partnerships

The story of Jaka Robotics on the market is characterised by constant growth, starting from China, and extending through South-East Asia and then arriving in Europe in 2022 through the technical/commercial branch in Germany. A geographical spread that allows it to follow customers in every aspect, offering constant assistance and really competitive supply times, thanks to the use of express airmail for deliveries.

The Italian service, developed with the collaboration of partners authorized at service level II, guarantees constant customer support and a very short supply chain made up of highly professional interlocutors.

«In Europe we can count on the collaboration of professionals in every country» explains Giacomo Mariotti who has held the position of country manager for Jaka Robotics since July 2023. «And this allows us to collaborate closely with system integrators in the development of projects, following customers step-by-step, according to a philosophy that doesn’t just aim at distributing the product, but at forming an integral part of our users’ business as innovation accelerators. We are working hard on our partnerships with high-level operators such as OnRobot, with which we have entered into an agreement specifically for developing plug-and-play kits in machine tending on various applications, which will be followed by palletizing and finishing. We have over 300 partners at European level that work with us and provide holding devices, vision systems, linear axes and software, with the aim of creating an ecosystem of simplified solutions which are ideal for customers. Schneider Electric, for example, has recently inserted our collaborative arm in its catalogue, demonstrating that Jaka is ready for the European market thanks to the wide range of testing and certifications, whether binding or optional».

It’s worth pointing out that, in Europe, besides technical assistance, Jaka Robotics also guarantees pre-sales application support, involving simulations and project studies, and offers free advanced training in all phases of product management, right from initial installation, without this excluding personalized courses in the field on the basis of the customer’s specific needs.

Zu, Pro, MiniCobo: solutions for all markets (also food-serving)

As we know, cobots are fully collaborative 6-axis robots, which allow operators to be freed from the most dangerous and repetitive jobs, in which the human being is the mind and the added value while the robot is a smart assistant, which stands in for the less demanding part of the job. And it is according to this paradigm that Jaka Robotics’s varied product range has been developed.

Precise and flexible

«Let’s start with the Zu line: full-optional with a very varied payload from 3 to 18 kg and 1300 mm of lateral reach – points out Mariotti - ideal for end-of-line applications in the food, pharma and cosmetics sectors. It should be underlined that there is a remarkable level of repeatability, with 2 hundredths of a millimetre declared, for a precision which is among our product’s points of strength. Another plus are the consumption parameters under 600 Watts, which make the line particularly sustainable.

The distinctive features are many, and include the possibility of integration in many packaging applications, with integration in the seventh and eighth axis and the insertion of linear axes and telescopic columns to expand the reachability of the robot. Wi-Fi programming, moreover, not only helps expand the application without the limitations caused by wiring, but permits programming offline from any Windows, Apple, or Android device; connecting to the router inside the cabinet, furthermore, activates the system to control the robot … an advantage for flexibility but also in the event of breakdowns, and soon will also be web-based.

The robot is full-optional and open to all the most common communication protocols: Profinet, TCP-IP, Modbus and Ethernet, and supports various programming languages such as Python, C++… In short, we do everything possible to simplify the life of users from every aspect. »

Maximum protection

Jaka Pro is also ideal for the packaging market, the only IP68 range in the world, about which Mariotti continues:

«The Pro is a fundamental step forward, because thanks to it being watertight, the robot can work in every type of environment, in ideal for serving in any market, from food to painting. An aluminium body, compressed air, also inside, completely revised servo-actuator design and a model with payload up to 16 kg, the Pro 16 with lateral reach of 1700 mm responds to the needs of the best end-of-lines. »

News for food serving

Designed specifically for serving food, the MiniCobo with 1 kg payload and 560 mm reach is already operating in new applications, like the supply of food to vending machines, managed online or from an app, in which the cobot manages the entire process, from ordering to serving the customer.

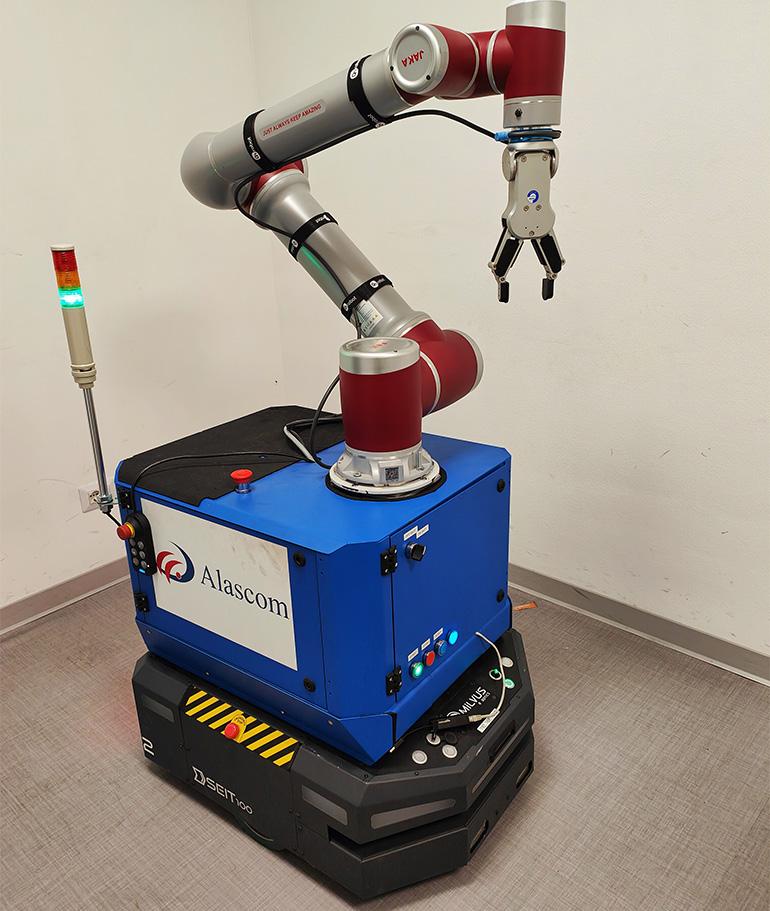

«Requests for food handling, especially from large chains, are many and of various types» Mariotti comments. «They are contexts in which the operator must be supported in placing the food on trays, but also in the display and in the management of all the repeatable elements typical of fast food, such as, for example, depositing hamburgers. A further application context for this small, great cobot is intralogistics, perhaps with the robotic arm on board AGVs or AMRs: we have, in fact, developed a version integrated with lithium battery power supply, a 2D vision system and torque force sensor to create servo applications with a mobile robot, strategic for improving work efficiency and quality. “Mobot” is, in fact, an Italian project developed with the Alascom partner which enables an AMR to carry out tasks in complete autonomy modifying, at the same time, the route in real time if the operator enters the movement area of the mobile robot».

Industry 5.0 ready, with an eye on the environment

With regards to the environment, finally, Mariotti offers us some considerations:

«Our robots are 4.0 ready and make it possible to download all the data, analysing operations from remote to study efficiency strategies as well as reduce consumption and waste. In general, consumption is extremely low and we are working on PDT (Performance Digital Traceability) green certification with a view to the imminent 5.0 transition.

It should be underlined that the characteristics of flexibility and mobility of a cobot makes it possible to drastically reduce occupied space, but most of all, to reconfigure production lines with a minimum operating cost, significantly reducing impacts in terms of costs and layout disruption, and with the optimisation of existing resources. We are focusing heavily on Italian SMEs, which often need to revamp existing lines and where Jaka technology can intervene effectively, supporting the automation of processes and modernizing existing plant. »

Advice for the correct use of cobots

Having studied at the Bocconi University, with specialisation in innovation and new technologies, Giacomo Mariotti kept his interest in these themes alive working first and foremost on interactive virtual reality for the industrial world. First export manager in internationally oriented companies, he finally reached robotics and AMR, mobile collaborative robotics, an authentic expression of the most advanced concepts of industry in the 4.0 and 5.0 evolutions. Since July 2023 he has held the position of country manager in Jaka Robotics, bringing to the company a wealth of concepts and ideas developed over time.

«In these years, I’ve taken active part in the development of collaborative robotics, trying to modify a widespread incorrect communication message in the early stages of its appearance. Cobots have long been presented as easy to use and install, bringing onto the market many devices that now lie unused due to lack of internal skills. The customer must be trained to understand that, to activate a successful project, they need quality consultancy, a system integrator who studies the context, develops a customized project and follows it through to installation. Specific training of staff is also needed to make the new technology a competitive asset of the company, as well as a commercial partner ready to assist the customer at all times».