Open digital ecosystems

Industry needs common standards so that other producers’ intelligent products, machines and equipment can interact dynamically and without constraints. The future of digital production must therefore incorporate open, transparent and secure ecosystems. This is the true revolution announced by Emerson Discrete Automation at the SPS trade fair.

Milena Bernardi

The fruit of the recent amalgamation of different business units, Emerson Discrete Automation, took part for the first time at SPS as a group team. Its participation at the fair was characterised by the broad offer of intelligent and integrated solutions enabling the achievement of ambitious production, safety and sustainability objectives in the context of “discrete production*” and automation in the factory.

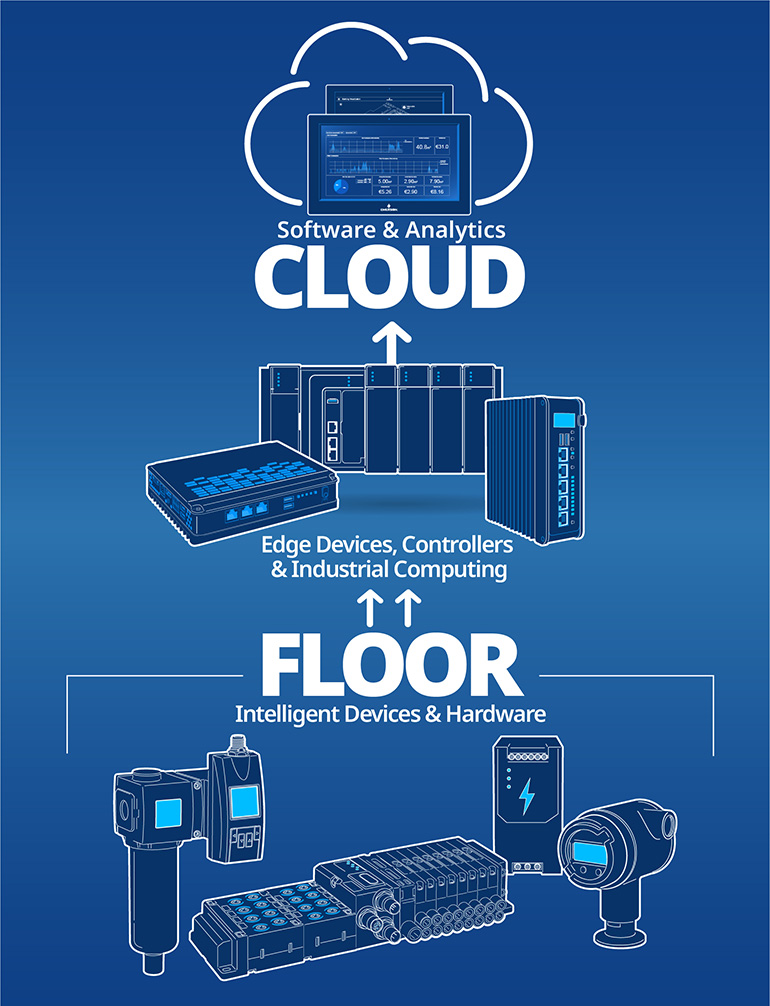

The new Floor to CloudTM approach promoted at SPS, therefore, raises the bar of efficiency in all production activities and makes it possible to manage an entire ecosystem starting from the bottom, with intelligent devices and single components able to communicate between each other through appropriate interfaces.

«Starting from the existing machine, through combined actions and real-time data management, we can arrive at cloud level, optimising the efficiency of systems to then demonstrate the profitability of investments and modify the control application in the field, in a simple and meliorative way» explains Martino Caranti, Emerson sales leader Italy and Israel who we met at the fair. «To achieve this, Emerson offers intelligent solutions able to clearly monitor the key parameters of processes stating from the single device right up to the entire system, allowing OEMs to take informed decisions on the management of the single machine, line or plant, based, for example, on real-time OEE data for each of these and for each production lot».

Designing flexible architecture

The true revolution, however, lies in enabling sensors that speak different languages to dialogue with each other: this means that components of different producers need to be connected in a flexible way.

The objective, therefore, is to distribute automatically scalable architectures, independent of the number of components and producers involved. In a scalable architecture, the components recognise each other and provide the same information to the environments and levels appropriate for visualising information, for example, on predictive maintenance, regardless of the dimensions of the system.

«Emerson develops preconfigured solutions that automatically recognise the components and immediately integrate them into the corresponding environments» continues Caranti. «In other words, it involves providing for open languages in order to construct veritable digital ecosystems that collect data and transmit them to the software for processing. The same software then extracts the most significant efficiency parameters and makes them available, both in loco and in remote, to those that have to use this data to take decisions».

Working on existing technologies

Most production plants are not necessarily new, but have been operating for some time. In this context Emerson Discrete Automation supports producers in making their products smart at various levels without having to redesign the entire machine, through appropriate extensions of the existing components or small integrations.

«We follow the “do more with less” logic: we have to help the customer to produce more with fewer resources, with a view to the optimisation of costs and sustainability»

Caranti pointed out, emphasizing that this is turn can become a competitive advantage for the same company. The service offered by Emerson is also moving in this this direction, offering customers the possibility to use simple development tools with which to demonstrate in advance, on a pilot scale, the profitability of investments at industrial level.

Digital sustainability

Acquiring awareness of energy consumptions to then calculate the potential economic savings is possible only in an adequately digitalised production environment. Together with customers, Emerson’s discrete production experts analyse processes and evaluate efficiency in real time on every single production lot, identifying practical ways to save energy and implement intelligent technologies that extract and evaluate extensive flows of data to provide key information and optimization levels. An informed decision-making process can significantly reduce environmental impact, improve energy efficiency and guarantee compliance with regulatory requirements.

With regards to future plans, Caranti reveals that Emerson will continue to develop cyber security solutions and continue to produce modulable and scalable systems with a life-cycle aligned to that of the machine hosting them.

«Priority objectives also include the development of the software division, aimed not only at integrating new solutions in portfolio, but also at ensuring greater engagement in the upgrading of controllers with dated software» the manager concludes.

*Note The term “discrete production” generally refers to a specific type of production that focuses on single and distinct articles (production of bottles, snacks, machines, that is, also complex objects that can be individually counted). This is distinguished from “continuous production”, typical of the processing world, in which the product is a flow (productions of tonnes of petroleum, kilos of salt, that is, products that flow with a sort of continuity).