From virtual to real

The state of the art in adhesive application: at Ipack-Ima 2022 Robatech welcomed customers and visitors by giving them the opportunity to touch on the many new products in the catalog, including specific solutions for e-commerce.

«The virtual event in March 2021, which had as its theme “The new dimension in gluing”, was a very important moment because it allowed us to reach thousands and thousands of people, but of course we are happy to be at the trade fair in Milan live to meet our customers and partners and physically show what we presented to them in digital format», makes it clear right away Davide Morten, Director of Robatech Italy.

Who, when asked about market trends in this first part of 2022, answers clearly: «In terms of sales trends, we are in line with forecasts. What we could not foresee is that the purchase costs of raw materials would rise so much. Not wanting to generate excessive market repercussions, we are nonetheless absorbing most of the increases, although it is inevitable that, even in our industry, some prices will be revised upward, although not as is the case in components»

Technology landscape

A leading provider of eco-friendly “solutions,” the latest product innovations, which already stand to set a new standard compared to what is available on the market today, were therefore on display: the smart melter, Vision; the electro-heated hose for high-precision adhesive applications, Performa; and finally the high-speed adhesive application head, SpeedStar Compact, but not only that...

Vivo 18

«For the occasion - Morten says - we have reserved a corner in our booth for the world of e-commerce, which is one of our main focuses globally for 2022. On display will be the products we make for the industry and, in particular, the new Vivo 18 coating head: precise, fast, and compact, it enables the application of high-quality hot glue to affix tear-off tapes and adhesive closures on shipping packages made of cardboard, paper, or film. The Vivo 18 ensures precise, even, clean-cut coating, thanks to the optimized adhesive distribution in the nozzle, the negative-closing element, and the ability to finely adjust the alignment of the nozzle itself to the substrate. Also not to be forgotten is the system’s small footprint and fast format change».

Vision

The new smart melter for the application of hot melt adhesives is gaining great acceptance.

«Vision is fully digital and connected via wi-fi with the operator, it is easy to install, flexible and sustainable because it provides good energy savings compared to any other traditional applicator we know. And I’m not just referring to Robatech systems, as we have had the opportunity to conduct measurement benchmarks on models from other brands». A focus was also placed on optimizing maintenance processes, with a single access door: «Vision is made to make life easy both for those who have to install it on their machines and for those who use it every day. Manufacturers who adopt it can leverage its technology to optimize machine performance. I make it clear, however, that the product is not intended to replace the traditional and reliable Concept series, as the two ranges complement each other by targeting different application ranges».

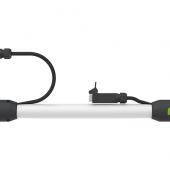

Performa

«These electro-heated hoses, suitable for low-viscosity thermoplastic adhesives and reactive adhesives, require up to 45 percent less energy than conventional devices. Advantages include the speed with which the operating temperature is reached, the fact that they do not have an outer mesh sheath but an abrasion-resistant plastic sheath, and the Prime Connect quick-connect system that allows the hoses to be hooked up and unhooked without the need for tools, Last but not least, the fact that they can also be used on dated systems, thus allowing, even for those who do not have the immediate need to renew the entire fusion system, to upgrade only certain parts».

Speedstar Compact

«Launched last year, these application heads are very compact, allow precision adhesive application at high production speeds, up to a maximum of 800 dots per second, and are capable of dispensing millimeter dots of hot melt glue and short beads on tiny tabs and small surfaces. Like all Robatech heads, they are insulated, in favor of energy conservation and operator safety».